A kind of nano-semiconductor photorefractive film material and preparation method thereof

A nano-semiconductor and thin-film material technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of complex process, material consumption, slow crystal growth cycle, etc., and achieve simple and easy preparation process, preparation The method is simple and easy, and the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

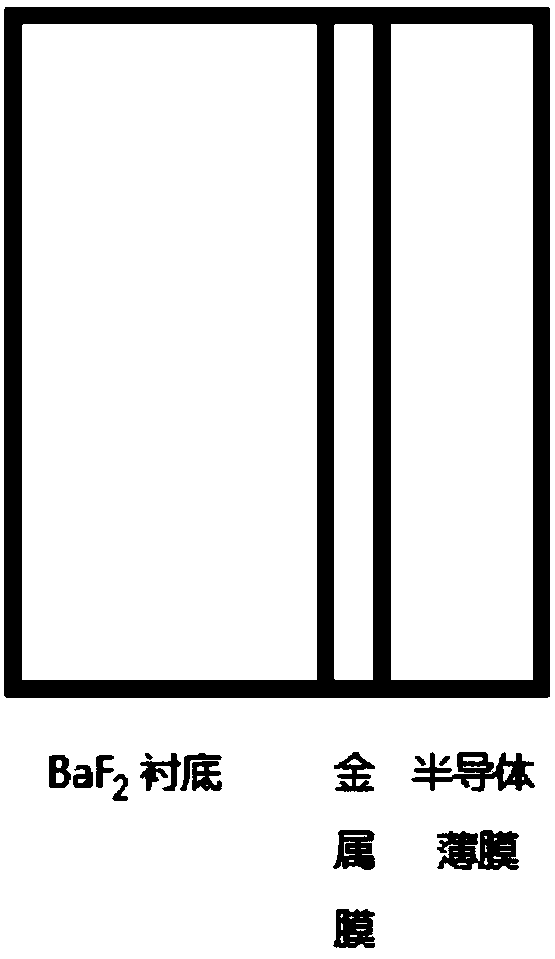

[0047] Wash BaF with absolute ethanol 2 Substrate, using 99.99% copper target, the sputtering chamber is evacuated to 5×10 -4 Pa, filled with argon, the working pressure of the sputtering chamber is 0.45Pa, the sputtering voltage is 300V, the current is 80mA, the sputtering rate is 0.08nm / s, and the sputtering time is 125s. 2 A transparent copper film of about 10nm is prepared on the substrate.

[0048] Using 99.99% PbTe target material, the sputtering chamber is evacuated to 5×10 -4Pa, filled with argon, the working pressure of the sputtering chamber is 0.45Pa, the sputtering power is 20W, the sputtering rate is 0.09nm / s, and the sputtering time is 1100s, so that a PbTe film of about 100nm is prepared on the transparent copper film, that is, BaF 2 / Cu / PbTe film.

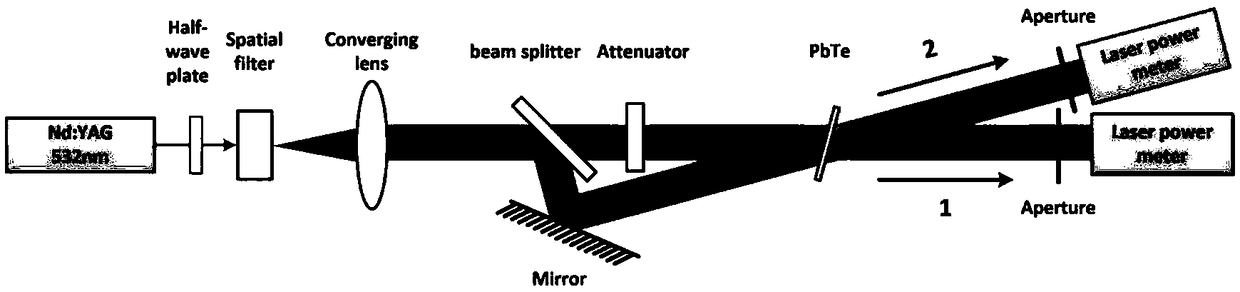

[0049] The prepared material structure is as figure 1 shown. BaF prepared by two-wave coupling experiments 2 / Cu / PbTe film for photorefractive effect test, such as figure 2 As shown, the two-wave coupling ex...

Embodiment 2

[0057] Wash BaF with absolute ethanol 2 The substrate is made of 99.99% PbTe target material, and the sputtering chamber is evacuated to 5×10 -4 Pa, filled with argon, sputtering chamber working pressure 0.45Pa, sputtering power 20W, sputtering rate 0.09nm / s, sputtering time 1100s, thus in BaF 2 A PbTe film of about 100nm is prepared on the substrate, that is, BaF 2 / PbTe film.

[0058] BaF prepared by two-wave coupling experiment 2 / PbTe film for photorefractive effect test, BaF 2 / PbTe film has weak photorefractive effect. The weaker photorefractive effect means that the diffraction efficiency of the grating obtained by taking pictures with a CCD (charge-coupled device) is very low, less than 0.1%, and the refractive index grating stripes read from the optical path diagram of the two-wave coupling experiment are very weak. BaF prepared in this embodiment 2 / PbTe thin film grating diffraction efficiency is very low, only 0.05%.

Embodiment 3

[0060] Wash BaF with absolute ethanol 2 Substrate, using 99.99% gold target, the sputtering chamber is evacuated to 5×10 -4 Pa, filled with argon, the working pressure of the sputtering chamber is 0.45Pa, the sputtering voltage is 340V, the current is 80mA, the sputtering rate is 0.19nm / s, and the sputtering time is 60s. 2 A transparent gold film of about 10nm was prepared on the substrate.

[0061] Using 99.99% PbTe target material, the sputtering chamber is evacuated to 5×10 -4 Pa, filled with argon, the working pressure of the sputtering chamber is 0.45Pa, the sputtering power is 20W, the sputtering rate is 0.09nm / s, and the sputtering time is 1000s, so that a PbTe film of about 100nm is prepared on the transparent silver film, that is, BaF 2 / Au / PbTe film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com