Clothes dryer and fault self-diagnosis method thereof

A fault self-diagnosis and dryer technology, which is applied to household dryers, washing machine control devices, textiles and papermaking, etc., can solve the problems that dryers cannot detect faults by themselves and maintenance is inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will describe in detail with reference to the drawings and embodiments, and the embodiments in the present application and the features in the embodiments can be combined without conflict.

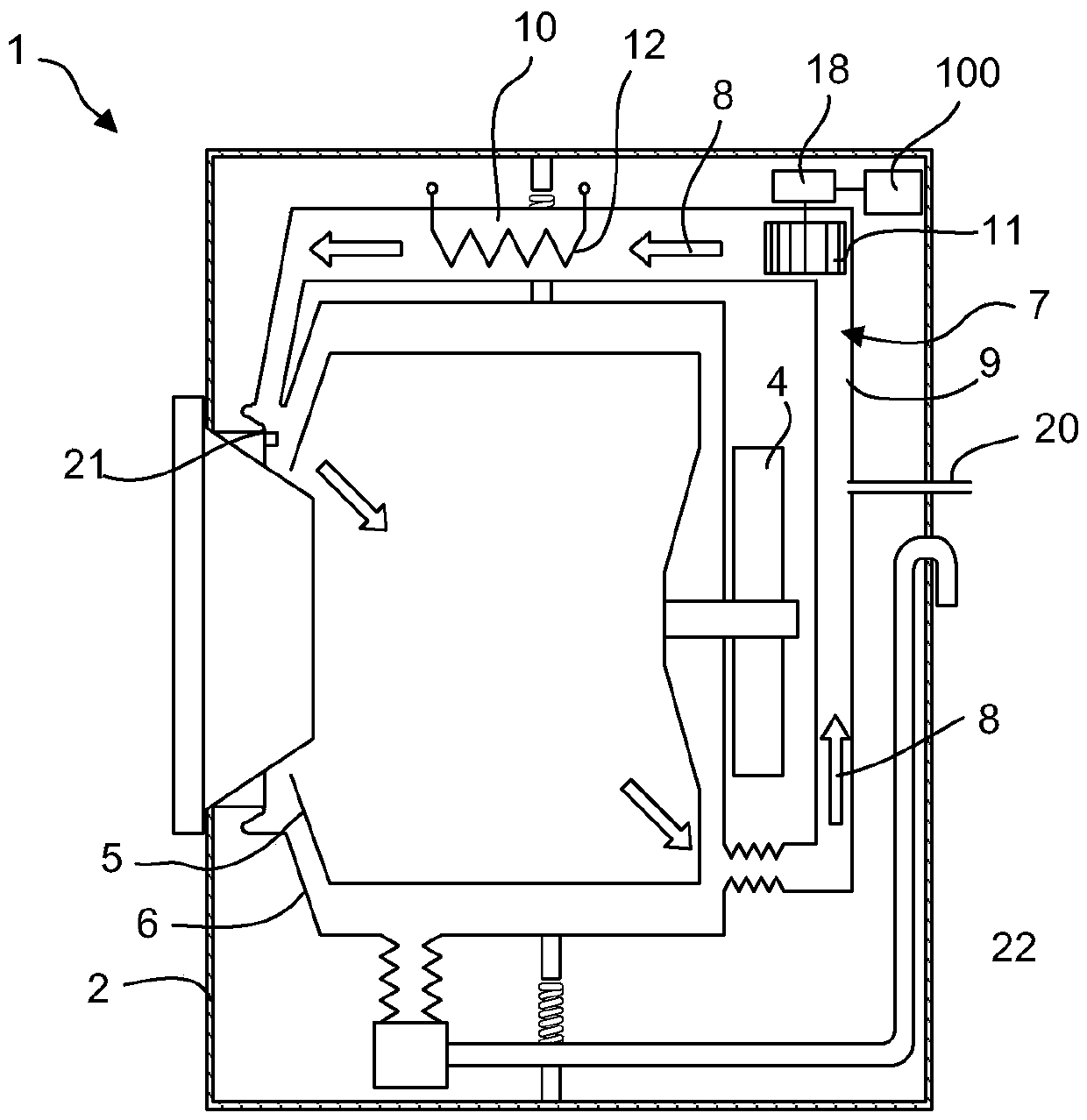

[0034] figure 1 For a side view of a clothes dryer, such as figure 1 As shown, the clothes dryer 1 has a cabinet 2, an inner tub 5 located in the cabinet 2 and driven by a main motor 4 to rotate, and an outer tub 6 (ie, a drying tub) set outside the inner tub 5 . The outer tub 6 is connected to the air channel 9 of the condensing device 7 and communicated in space. The air channel 9 of the condensing device further connects the fan 11 and the air heating channel 10 in sequence. The other end of the air heating channel 10 is then in spatial communication with the tub 6 .

[0035] In the drying process, the heater 12 (heating device) in the air heating channel 10 heats the drying air 8 flowing through it; the heated high-temperature drying air 8 enters the inner barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com