Sewer structure

A gutter, the same technology, applied in the field of gutter structure, can solve the problems of increasing the cable length, affecting the process flow, etc., achieving the effect of simple structure, reasonable design, and eliminating the need for line planning and redesign

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

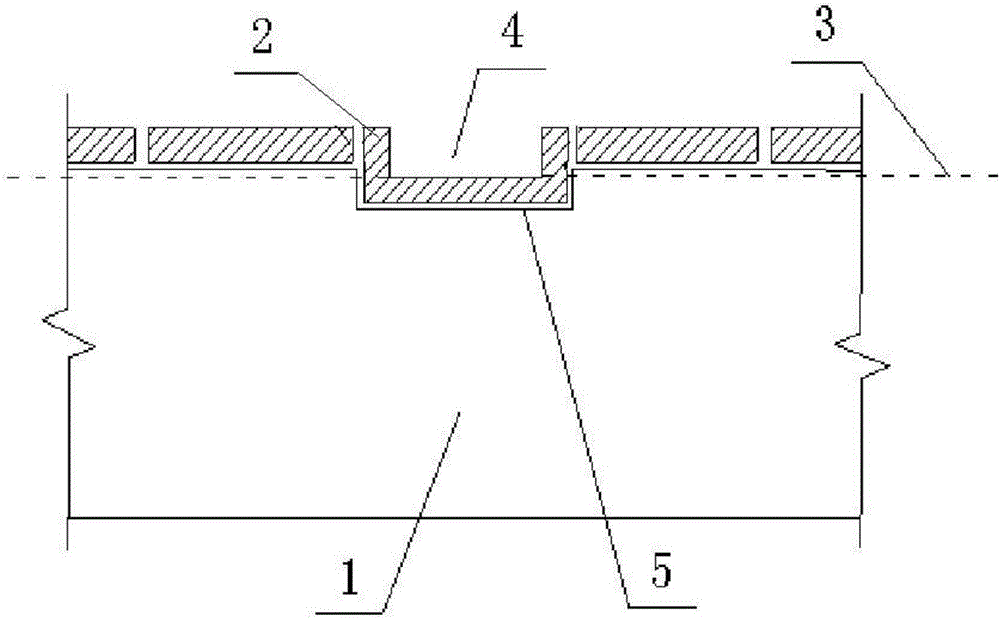

[0012] Such as figure 1 As shown, a gutter structure includes a gutter body 1 buried under the ground 3 and a gutter cover 2 arranged on the top of the gutter body 1 , and the top of the side wall of the gutter body 1 is higher than the ground 3 on both sides. The gutter cover 2 is provided with a rainwater aqueduct 4 communicating with the ground 3 on both sides of the gutter body 1 , and the inner bottom surface of the rainwater aqueduct 4 is on the same level as the ground 3 on both sides of the gutter body 1 . A groove 5 corresponding to the rainwater aqueduct 4 is provided on the top of the side wall of the gutter main body 1 . The cross-section of the rainwater aqueduct 4 is in the shape of a "mouth" with an upper opening, which can maximize the flow of rainwater through the rainwater aqueduct 4, reducing the possibility of excessive rainwater flow and causing water accumulation.

[0013] In normal use, when rainwater is discharged from the factory building to the gutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com