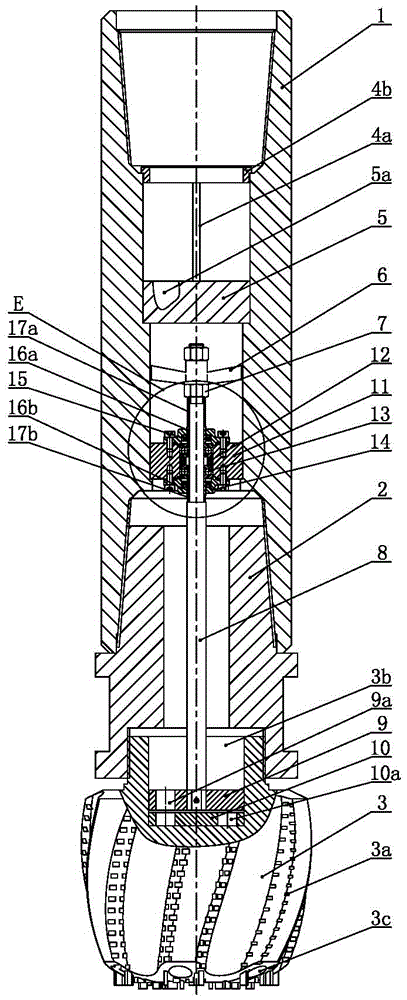

Equal flow pulse jet drilling bit device and design method thereof

A technology of pulse jet and design method, which is applied in the direction of drill bits, drilling equipment, drilling with liquid/gas jet, etc. It can solve the problems of not realizing equal flow pulse jet, etc., so as to improve the ability of rock cleaning and rock breaking, reduce the failure rate of equipment, The effect of increasing ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

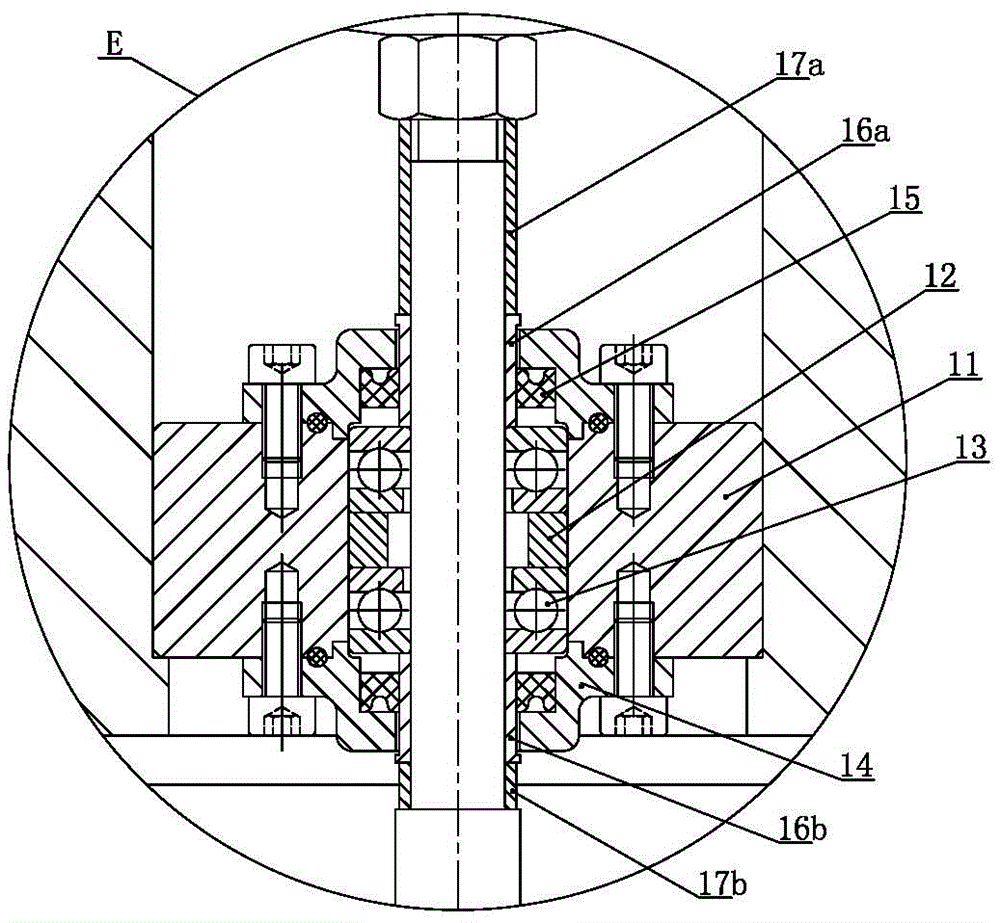

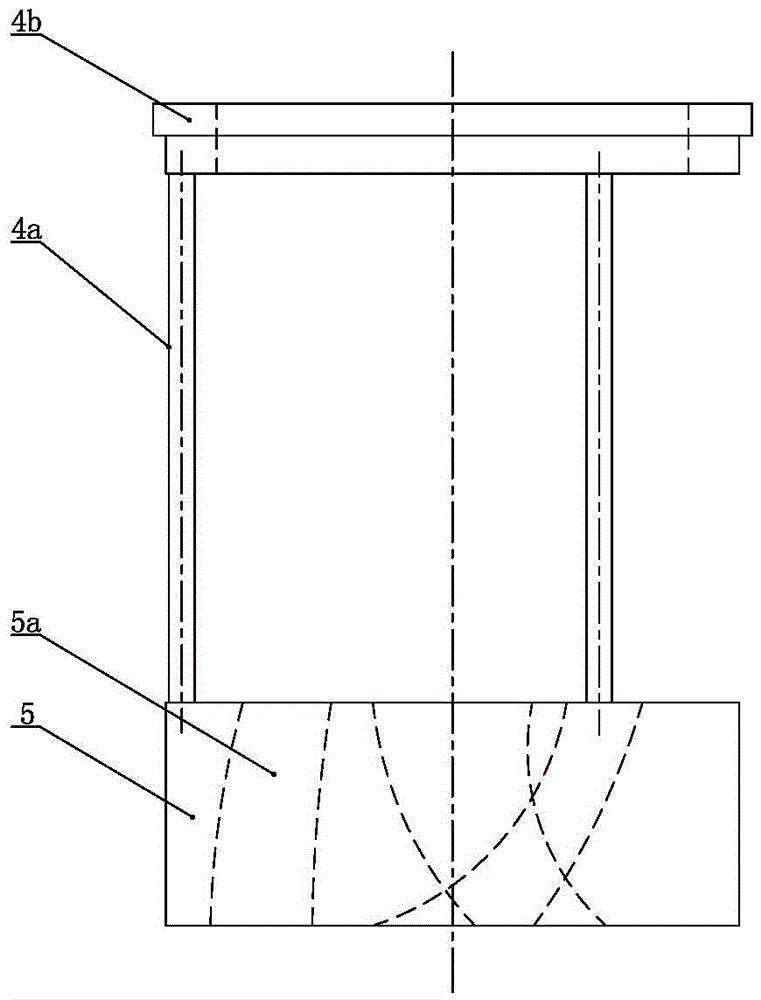

Embodiment approach

[0053] like Image 6 As shown, as the first embodiment of the present invention, the number n of static valve disc water holes is 3, the number m of fan-shaped ring holes is 2, and the central angle of the first movable valve disc fan-shaped ring hole A1 is Φ 1 , the central angle of the sector ring hole A2 of the second moving valve disc is Φ 2 ; When the first radial side of the fan-shaped ring hole A1 of the first movable valve disc rotates to the second tangent line with the water hole B1 of the first static valve disc, the second diameter of the fan-shaped ring hole A2 of the second movable valve disc The side is inscribed with the second tangent line of the water hole B3 of the third static valve disc. At this time, the second radial side of the fan-shaped annular hole A1 of the first dynamic valve disc is inscribed with the first tangent line of the water hole B2 of the second static valve disc. The angle between them is θ 1 , the angle between the first radial side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com