Yaw vibration noise digestion device for sliding bearing of wind generating set

A technology for wind turbines and sliding bearings, which is applied to wind turbines, wind power generation, engines, etc., and can solve problems such as difficulty in eliminating yaw vibration and noise, vibration and noise, and affecting the safety and reliability of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

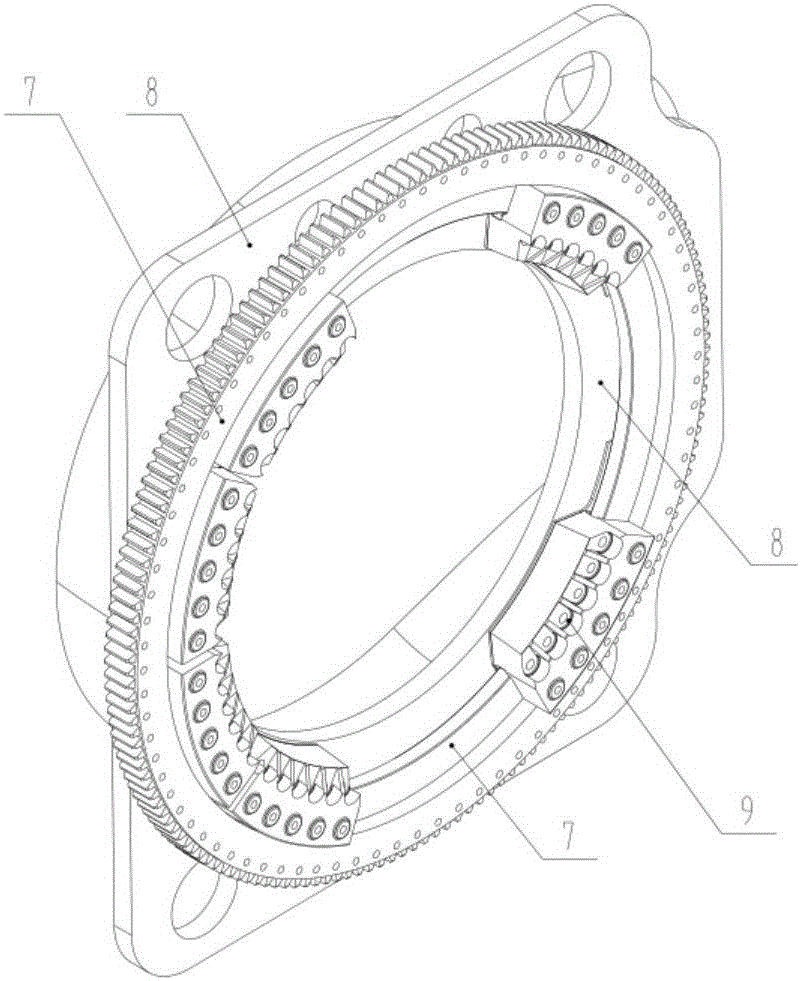

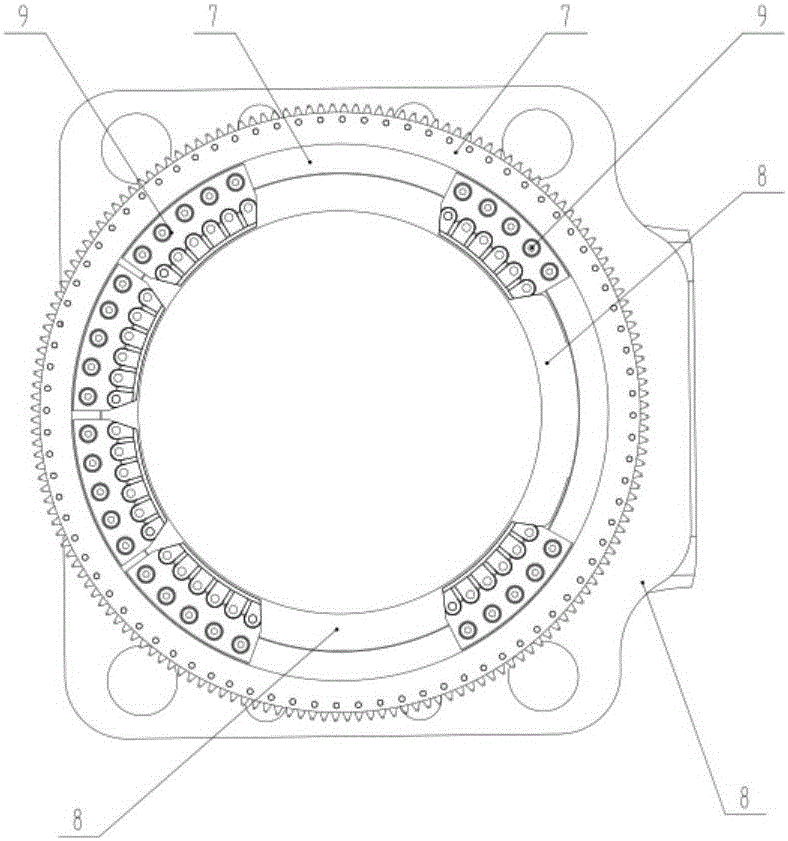

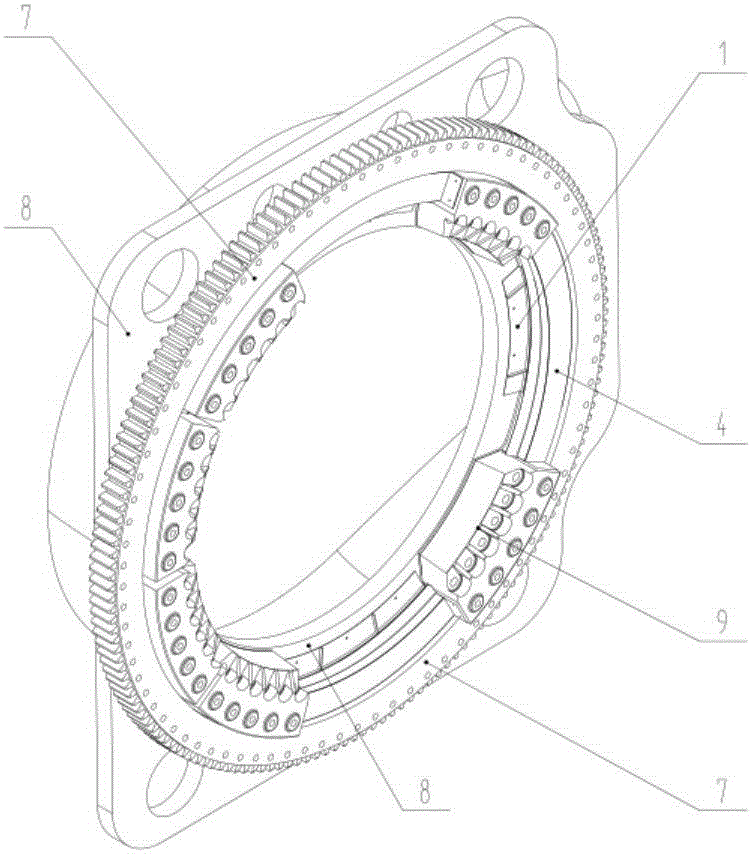

[0024] The present invention will be further explained below in conjunction with the drawings:

[0025] As shown in the figure, the present invention provides a device for eliminating yaw vibration and noise of the sliding bearing of a wind turbine generator, which includes a yaw ring gear 7, a main frame 8 and a lateral support 9. Vibration element support assembly G1, special assembly F2, anti-vibration element E3, support assembly 4 of the anti-vibration element on the lower surface of the yaw ring gear, special assembly B5, and anti-vibration element 6; the anti-vibration element E3 is installed in the support assembly G1 On the upper part, the special component F2 is against the anti-vibration element E3, and the anti-vibration element E3 is brought into contact with the friction surface of the yaw ring gear 7 through the special component F2, and the bracket assembly G1 is connected to the main frame 8; the anti-vibration element 6 is installed on the bracket On the assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com