Slewing bearing with overload alarming function

A technology of slewing bearings and functions, which is applied in the direction of rotating bearings, centrifugal force-resistant rotating parts, bearings, etc., can solve the problems of long replacement or maintenance of slewing bearings, broken rolling elements, high working frequency, etc., to avoid economic and Loss of social benefits, prevention of emergencies, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is further described.

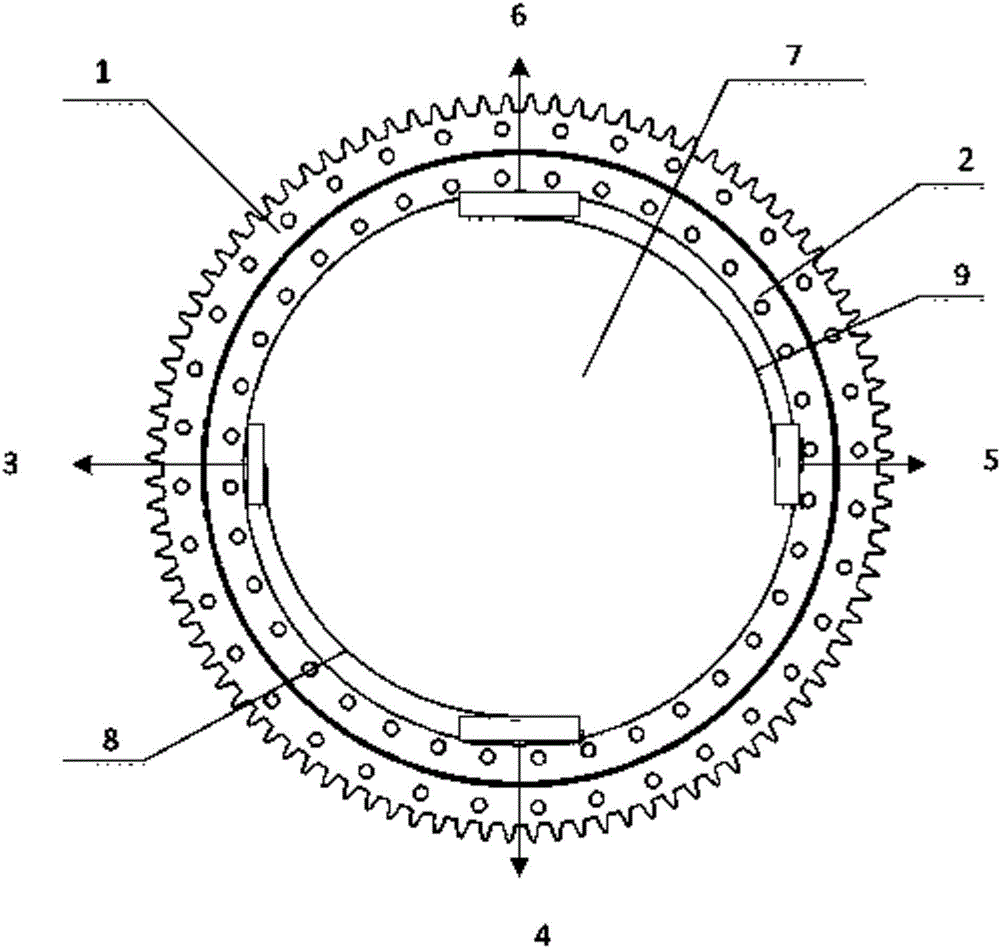

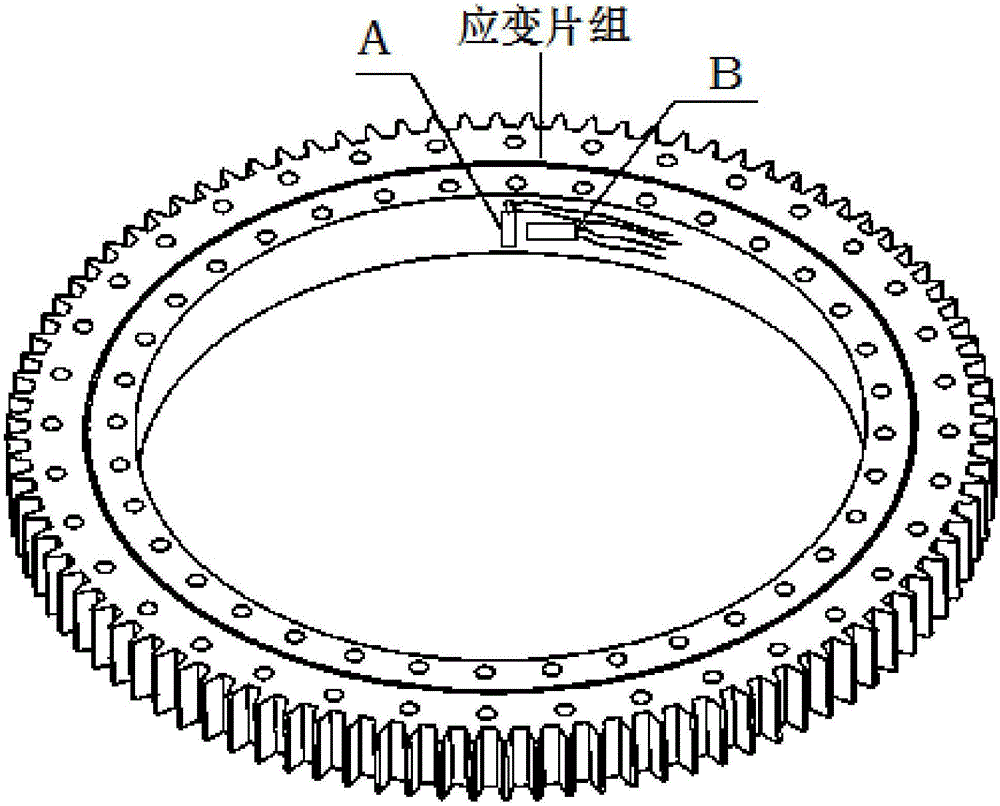

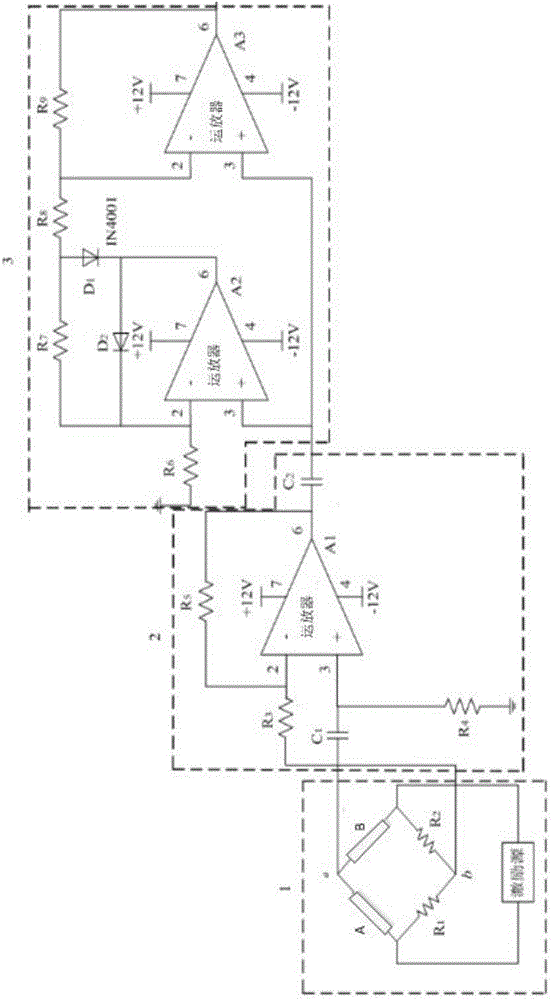

[0028] Such as figure 1 As shown, a slewing bearing with an overload alarm function includes a slewing bearing (7), and the slewing bearing includes an inner ring (2) and an outer ring (1), and also includes a first data acquisition module (4) and a second data acquisition module A module (6), a first set of strain gauges (1) and a second set of strain gauges (2). The first strain gauge group (1) and the second strain gauge group (2) are installed symmetrically and pasted on the inner ring (2), and the angle difference between the two strain gauge groups is 180 degrees. The first data acquisition module (4) and the second data acquisition module (6) are installed in the inner ring (2), and the signals of the first strain gauge group (1) and the second strain gauge group (2) are respectively output through the first cable (8) and the second cable (9) are connected with the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com