A sealing protection device for transmission shaft roller products

A sealing protection and transmission shaft technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of affecting the production progress, glass glue falling off, and inconvenient maintenance at the machining site, and achieve the goal of easy promotion and application, easy to use. Good operation and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

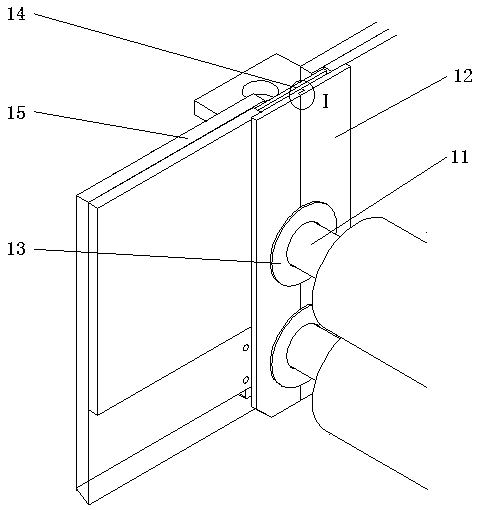

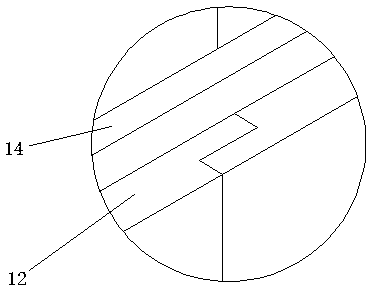

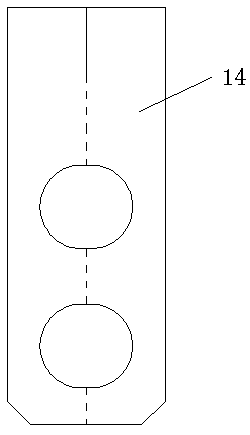

[0017] like figure 1 As shown, a sealing protection device for transmission shaft and roller products is provided. A set of sealing protection devices are respectively provided at both ends of the transmission shaft 11. The sealing protection device includes a tight-fitting sealing rubber ring 13, a slotted liquid separator 12 And the sealing baffle 14, the end of the transmission shaft 11 is sequentially sleeved with a tight-fitting sealing rubber ring 13, a slotted liquid separator 12, a tight-fitting sealing rubber ring 13 and a sealing baffle 14, and the sealing baffle Adopt plastic welding torch to weld between plate 14 and the frame wallboard 15 of the supporting equipment of transmission shaft roller.

[0018] A preferred solution is that the position of the shaft sleeve of the transmission shaft 11 is covered with rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com