Layering ventilation plywood airing support

A board drying rack and board drying technology, applied in the direction of veneer drying, lighting and heating equipment, drying, etc., can solve the problems of veneer scratches, uneven quality of finished products, affecting surface quality, etc., and improve the quality of finished products , easy to take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, referring to the drawings, through the description of the embodiments, the specific embodiments of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, etc. The detailed description.

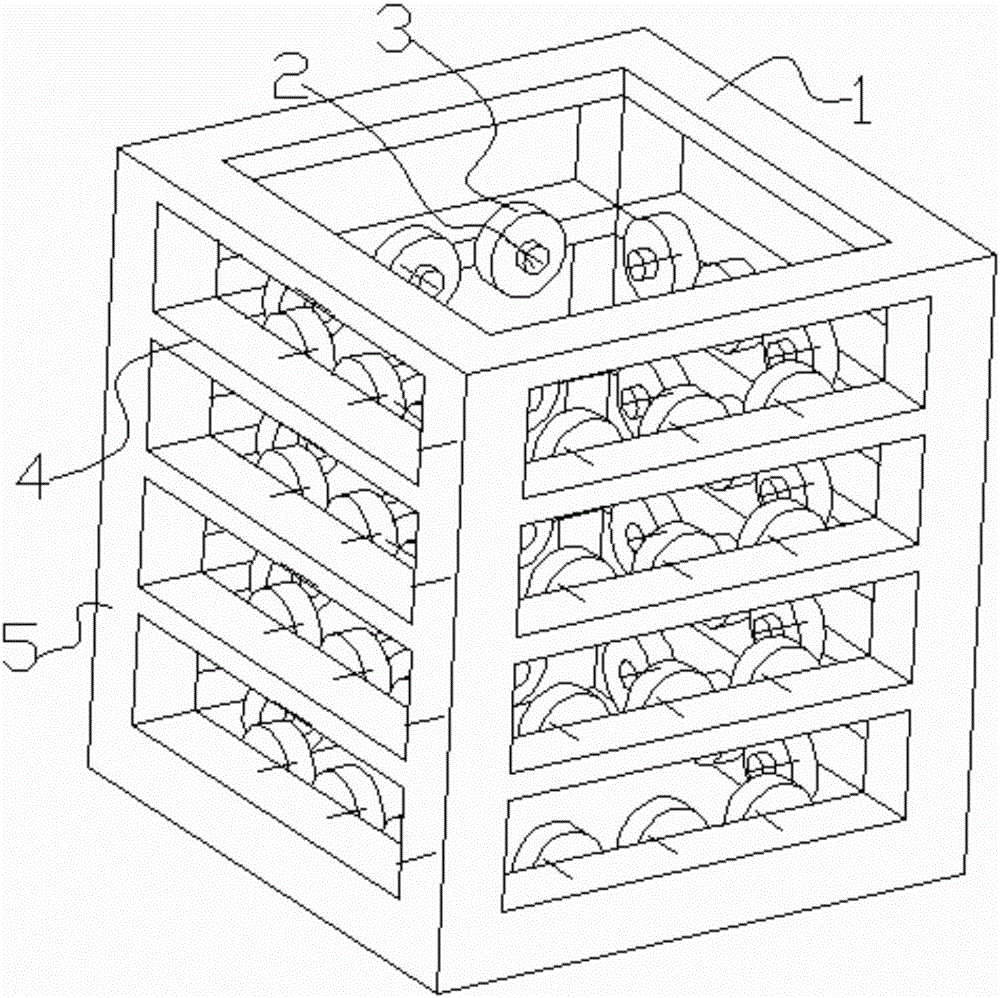

[0013] Such as figure 1 As shown, the layered air-permeable drying rack includes a drying board support 1, a roller shaft 2 and a roller 3. The drying board support 1 is a cubic hollow frame structure, the roller 3 is stringed on the beam 4 through the roller shaft 2, and the beam 4 is fixed horizontally On the frame of the drying board support 1, a cross beam 4 is set between two adjacent frames 5 of the cube frame. The beam 4 is arranged in multiple layers in the cube frame of the drying board support 1, and each layer is arranged in parallel. The height of the roller 3 is higher than the horizontal plane formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com