Rolling linear guide rail pair slider profile accuracy measurement method

A vice-slider-type, linear guide technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as low cost, inability to measure the data of the inner raceway in real time, and a blank on-line detection of profile accuracy. Achieving a novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

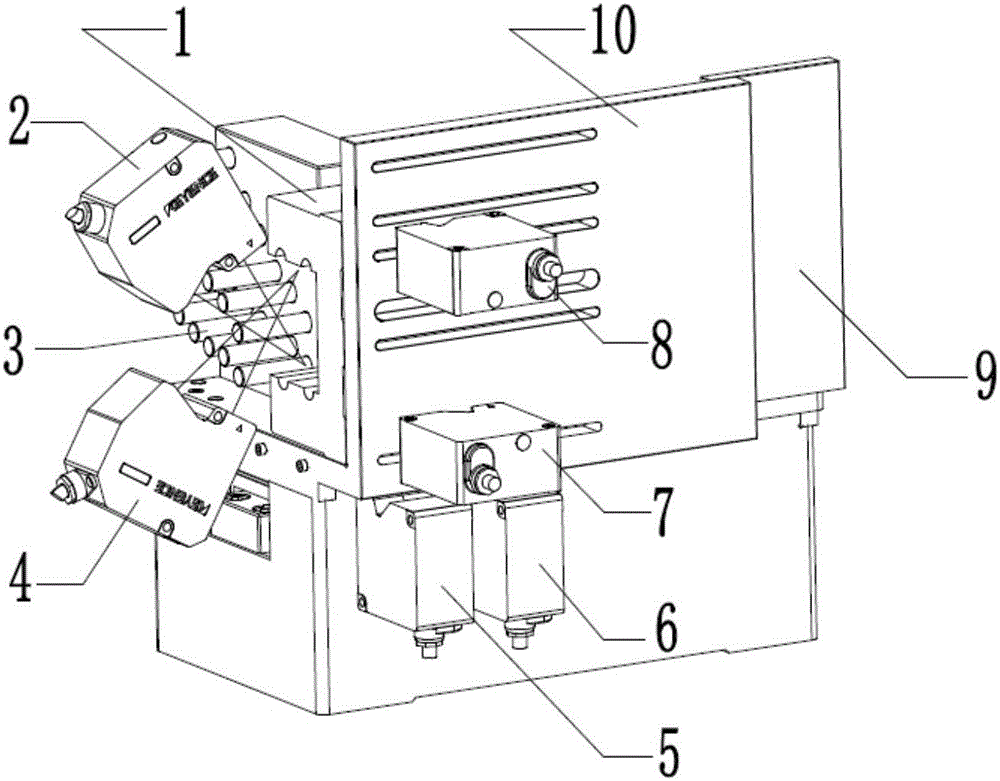

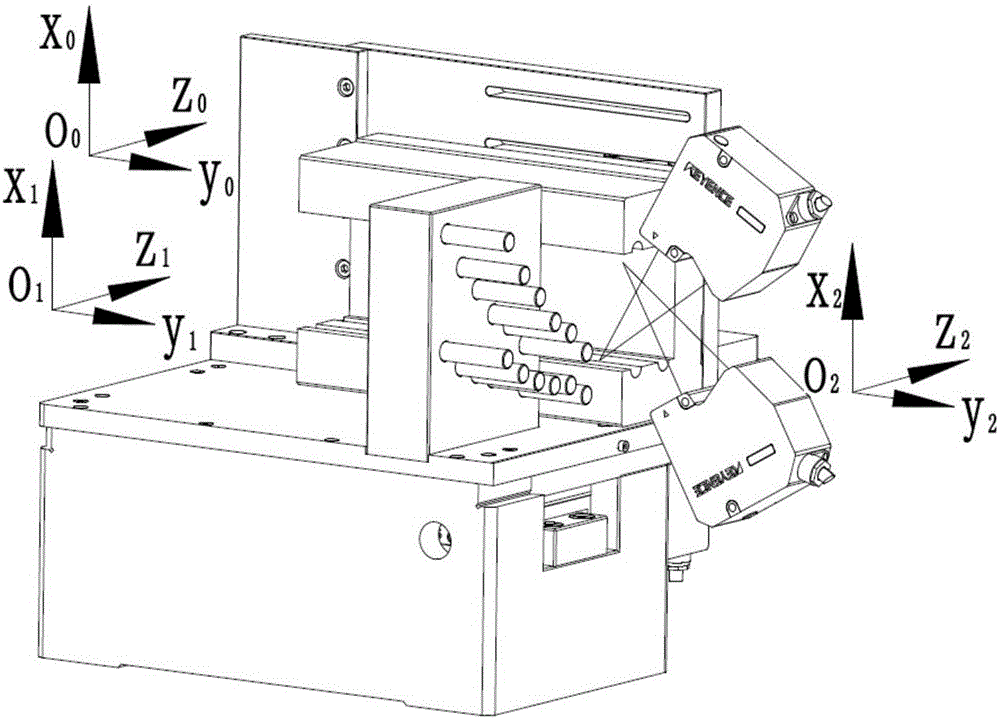

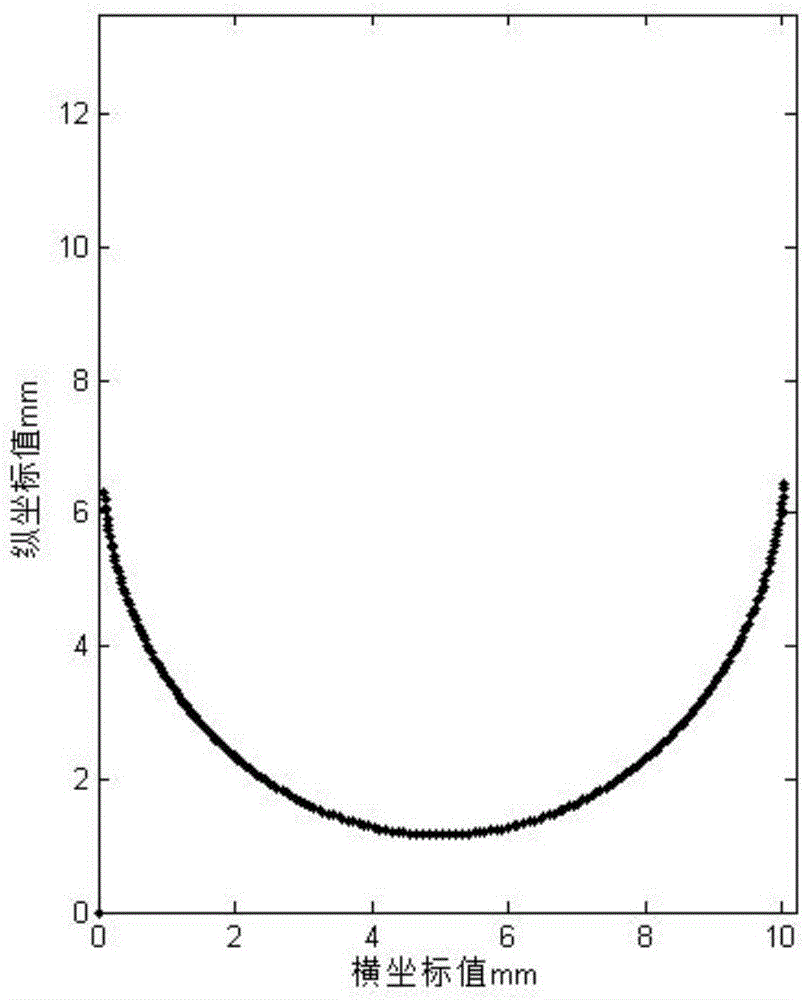

[0213] Combination of Profile Accuracy Detection of Rolling Linear Guide Rail Auxiliary Slider figure 1 , figure 2 To illustrate, the calibration block [9], the calibration cylinder combination [3] and the fixture table [10] are correctly installed and fixed. The measured diameter of the calibration cylinder is 9.996mm, the roundness is 0.003mm, and the straightness is 0.003mm. The first laser displacement sensor [2], the second laser displacement sensor [4], the third laser displacement sensor [5], the fourth laser displacement sensor [6], the fifth laser displacement sensor [7], the sixth laser displacement sensor The measurement system composed of [8] can simultaneously move along the y 2 axis movement, while the measurement system composed of the first laser displacement sensor [2] and the second laser displacement sensor [4] can simultaneously move along the z 2 Axis movement, that is, the measurement system composed of the first laser displacement sensor [2] and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com