Plying-up type main transformer thermometer

A technology of thermometer and protective cover, applied in the field of fitted main variable thermometer, can solve problems such as damage, difficulty in waterproofing, power failure and replacement, etc., and achieve the effects of being beneficial to waterproofing, saving manpower and reducing working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

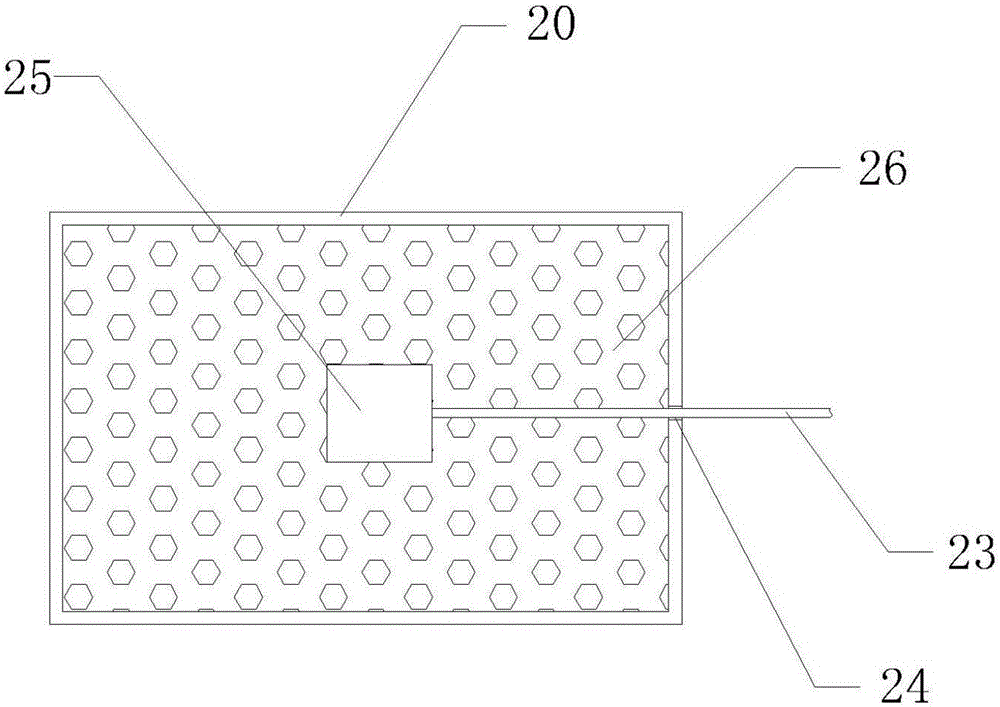

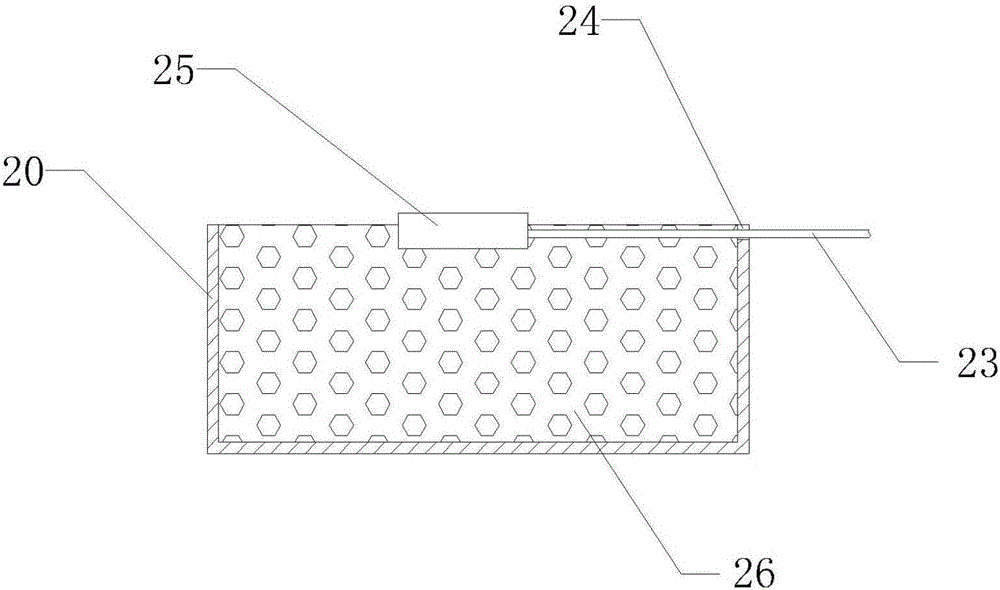

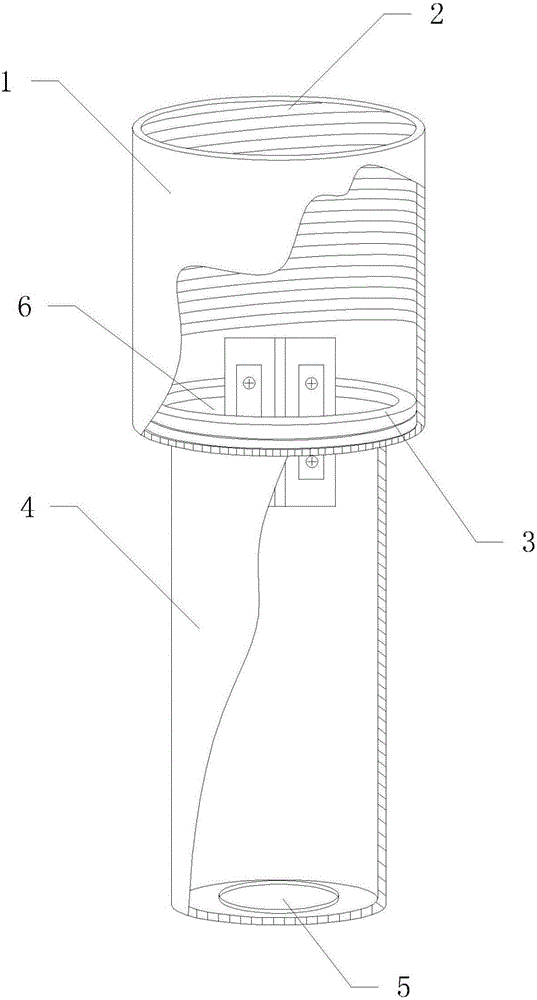

[0032] Example: such as figure 1 , 2 As shown, the bonding type main transformer thermometer includes a plastic protective cover 20, an opening is provided on one side of the protective cover 20, a thermal resistor 25 is provided at the opening, and a thermal resistor 25 is provided between the protective cover 20 and the thermal resistor 25. The thermal insulation layer 26, the thermal resistance 25 is connected with a secondary cable 23, and the secondary cable 23 is connected with an adapter.

[0033] The heat insulation layer 26 can reduce local heat dissipation, so that the measured temperature is closer to the actual top layer oil temperature.

[0034] The heat insulation layer 26 is made of foam plastics and fills the entire protective cover 20 . The heat insulation layer 26 is provided with a groove, and the thermal resistor 25 is arranged in the groove.

[0035] The protective cover 20 is rectangular, and the protective cover 20 is provided with a gap 24 for allowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com