Main transformer insulation paper vacuum sampling device and implementation method of vacuum sampling

A technology of sampling device and insulating paper, which is applied in the direction of sampling device, etc., can solve the problems of easily damaged insulating paper, main transformer winding and high-voltage lead wire insulation damage, irregular pattern of insulating paper, etc., and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

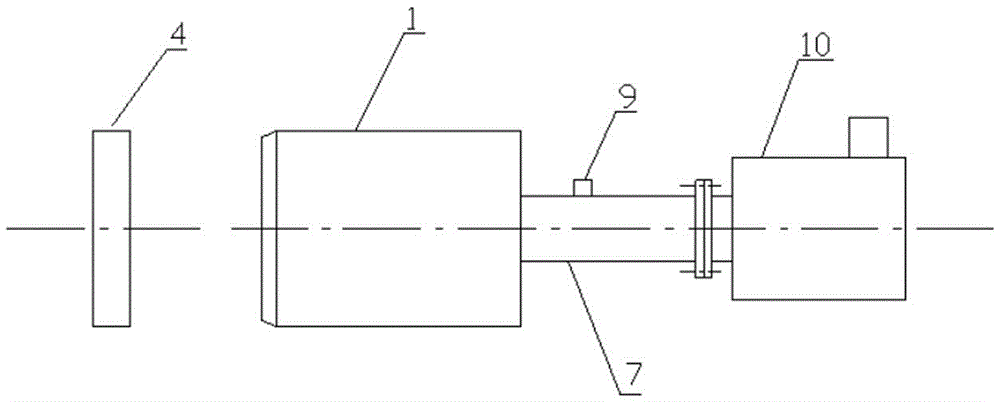

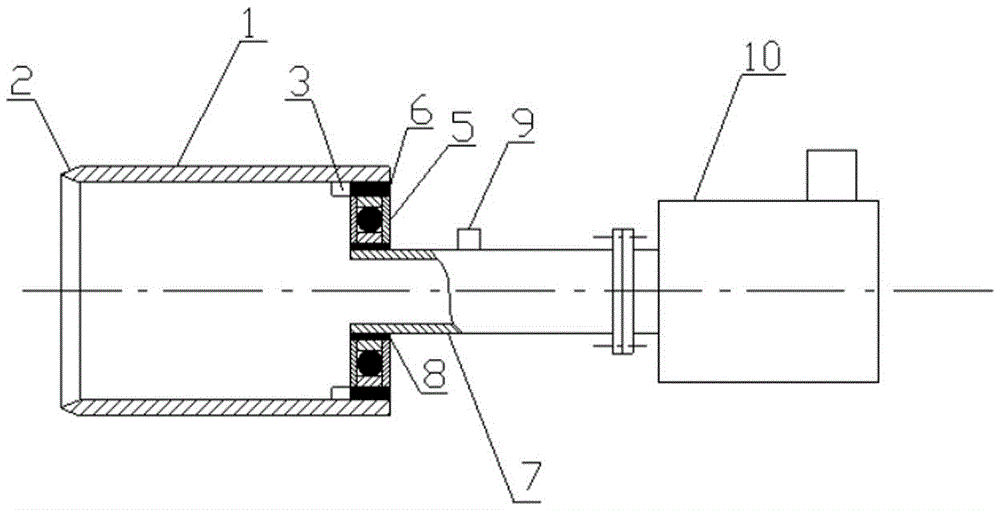

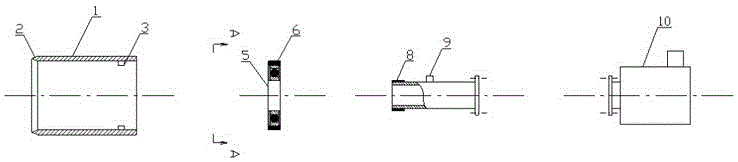

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] Please refer to Figure 1 to Figure 4 , the present invention provides a vacuum sampling device for main transformer insulating paper, which is characterized in that it includes a rotary sampling cylinder 1, the head of the rotary sampling cylinder 1 is provided with an annular blade 2, and the tail of the rotary sampling cylinder 1 is connected to a sealed bearing 5, the inner ring of the sealed bearing 5 is connected to one end of a connecting pipe 7; in the case of keeping the connecting pipe 7 still, the rotary sampling cylinder 1 can rotate around its central axis, and the annular blade 2 is opposite to the main transformer. The sampling site of the insulating paper is rotated and cut. The other end of the connecting pipe 7 is connected with an air extraction port of a vacuum pump 10, and the rotary sampling cylinder 1 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com