Ice core drilling device

A drilling and ice core technology, applied in the direction of sampling devices, etc., can solve the problems of ice layer damage, rough ice core surface, ice core breakage, etc., and achieve the effect of avoiding damage, ensuring smoothness and flatness, and convenient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

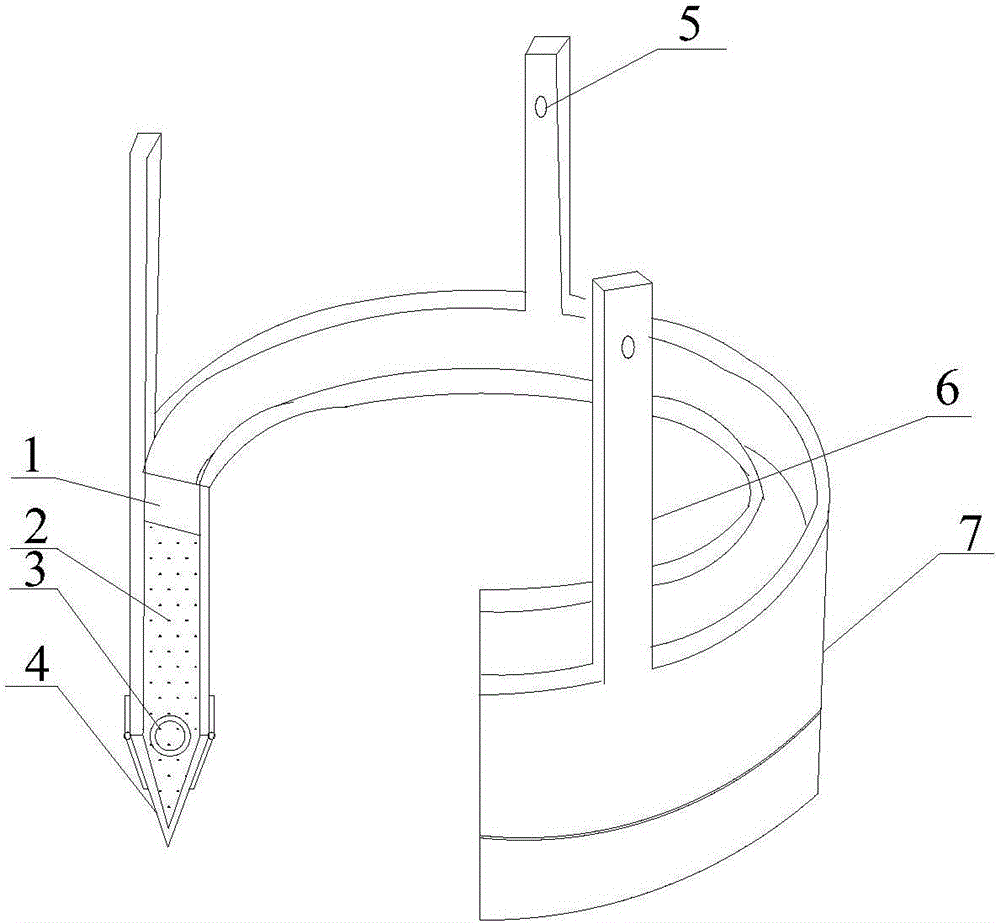

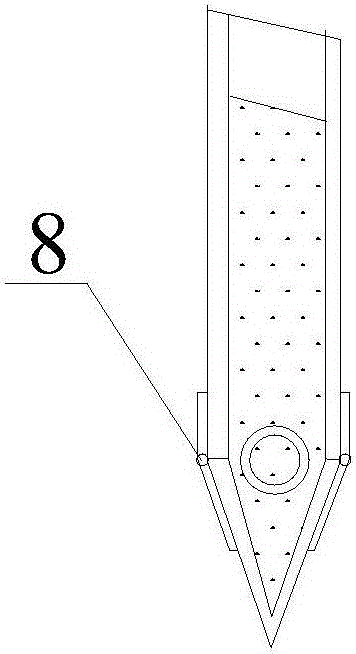

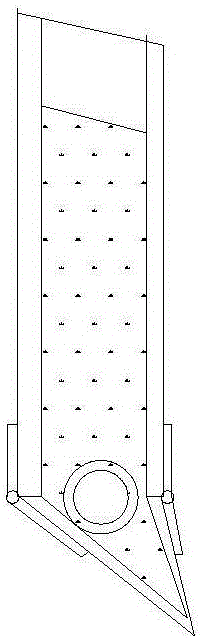

[0029] Such as Figure 1-5 As shown, this embodiment provides an ice core drilling device, including an ice core cylinder, a drilling mechanism and a control center, the drilling mechanism is fixed on the bottom side of the ice core cylinder; the drilling mechanism includes a drilling mechanism main body 7 , the heating wire 3 and the heating head 4, the main body 7 of the drilling mechanism is a hollow ring, the top of the main body 7 of the drilling mechanism is provided with a sealing cover 1, the heating head 4 is an annular shape with an inverted triangle in cross section, and the heating head 4 The interior of the heating head 4 is sealed and communicated with the bottom end of the drilling mechanism main body 7 through a plurality of electric joints 8. The inside of the connection between the drilling mechanism main body 7 and the heating head 4 is wound with a heating wire 3, the heating wire 3 and the electric heating wire 3. The joints 8 are all electrically connecte...

Embodiment 2

[0032] Such as Figure 1-5 As shown, the present embodiment provides an ice core drilling device. On the basis of the first embodiment, the ice core drilling device of the present embodiment also has the following characteristics:

[0033] Both the main body 7 of the drilling mechanism and the heating head 4 are made of metal, which is conducive to heat conduction.

[0034] The outer side of the heating wire 3 is covered with a ceramic ring, which has the properties of high temperature resistance, fast heat transfer and good insulation.

[0035] Both the drilling mechanism main body 7 and the internal empty positions of the heating head 4 are filled with magnesium oxide powder 2 .

[0036] The ice core drilling device also includes a connecting sleeve 10, the top of the drilling mechanism main body 7 is integrally provided with at least two connecting rods 6, the connecting rods 6 are provided with threaded holes 5, and the corresponding positions of the connecting sleeve 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com