Diameter determining method for calibrating standard substance of PM2.5 and PM10 cutter

A standard material, PM2.5 technology, applied in the field of standard materials, can solve the problem that aerodynamic standard particles cannot be traced, there is no PM2.5 and PM10 cutter cutting characteristics to detect aerodynamic standard particles, and PM2.5 and PM10 cannot be detected Cutter cutting characteristics detection calibration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

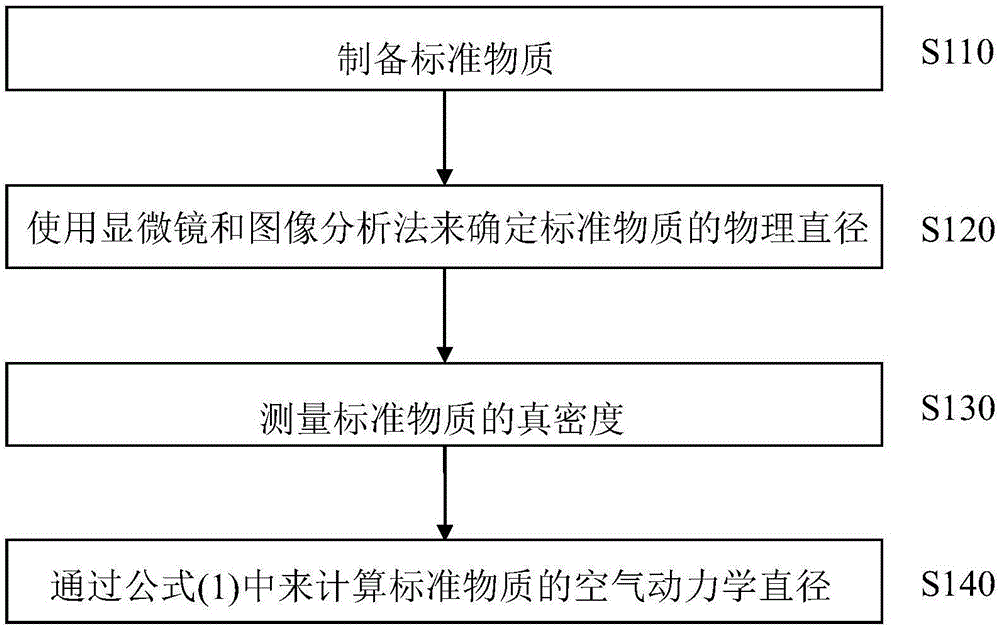

[0046] Embodiment 1, the fixed value that is used for calibrating the standard substance of PM2.5 cutter

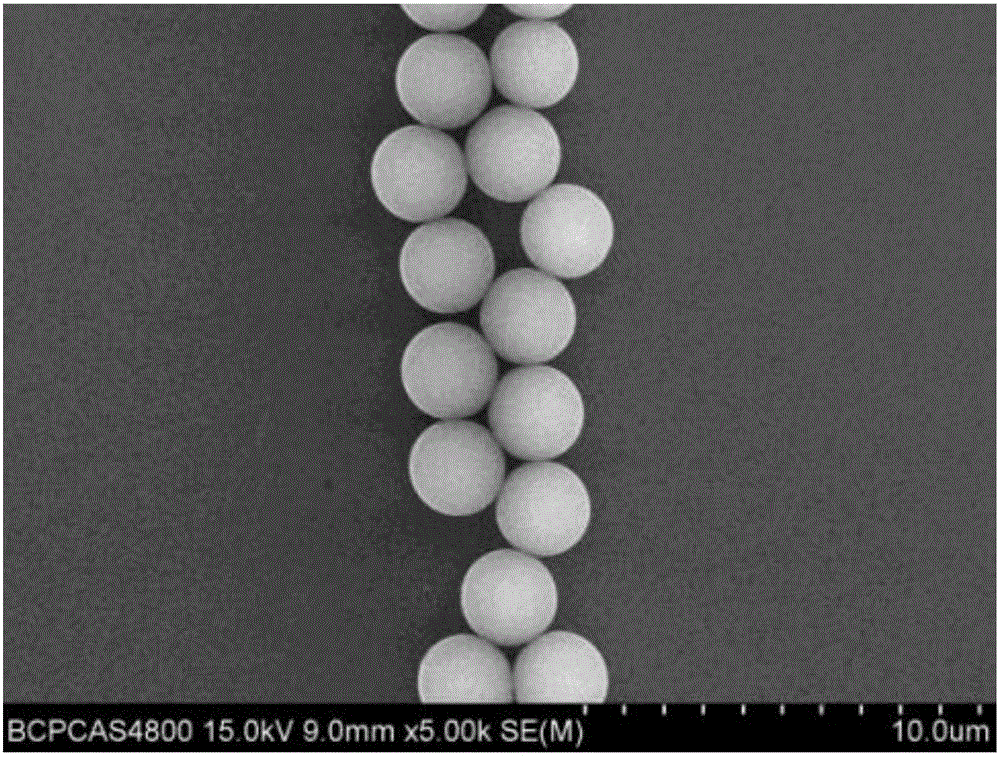

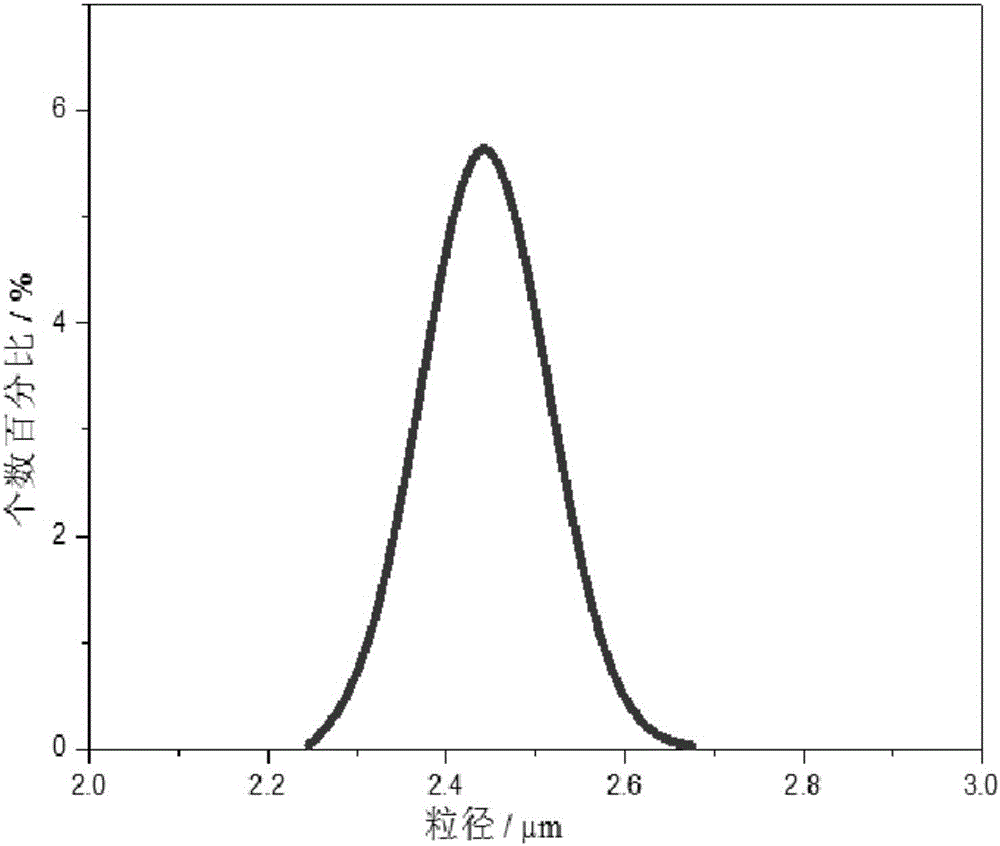

[0047] The first step is to prepare standard materials for calibrating the PM2.5 cutter (8 kinds of aerodynamic nominal diameters are 1.5 μm, 2.0 μm, 2.2 μm, 2.5 μm, 2.8 μm, 3.0 μm, 3.5 μm and 4.0 μm respectively. μm spherical monodisperse cross-linked polystyrene particles): Preparation steps: Dissolve 2.2g of polyvinylpyrrolidone in a mixed solution of 190mL of ethanol and 16mL of deionized water as the water phase, 0.5437g of azobisisobutyronitrile and 0.0622 g of divinylbenzene was dissolved in 45mL of styrene as the organic phase; reaction steps: adding the organic phase to the water phase, adjusting the stirring speed to 300r / min, and reacting at 69°C for 20h to obtain an emulsion sample; and separation steps: Emulsion samples were washed by centrifugation with ethanol and deionized water for 3 times to remove unreacted dispersants, initiators and styrene; then th...

Embodiment 2

[0057] Embodiment 2, the fixed value that is used for calibrating the standard substance of PM2.5 cutter

[0058]The first step is to prepare the standard substance used to calibrate the PM10 cutter (composed of 7 aerodynamic nominal diameters D ae Spherical monodisperse cross-linked polystyrene standard particles of 5.0 μm, 7.0 μm, 9.0 μm, 10 μm, 12 μm, 14 μm and 18 μm respectively): preparation steps: mix 4.90 g of polyvinyl alcohol and 2.24 g of sodium dodecylsulfonate (SDS) was dissolved in 100mL deionized water as the continuous phase, 0.93g benzoyl peroxide and 3.12g divinylbenzene were dissolved in 16.5mL styrene as the dispersed phase; reaction steps: the dispersed phase was added to the continuous phase, adjusted The stirring speed is 230r / min, react at 85°C for 10h, and obtain the emulsion sample; and separation step: wash the emulsion sample with deionized water several times to remove unreacted reactants, and then place the emulsion sample in deionized water Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com