True triaxial test method for simulating shearing type rock burst

A test method, true triaxial technology, applied in the direction of testing the strength of materials, measuring devices, instruments, etc. by applying a stable shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the embodiments described here are for illustration only and do not limit the invention.

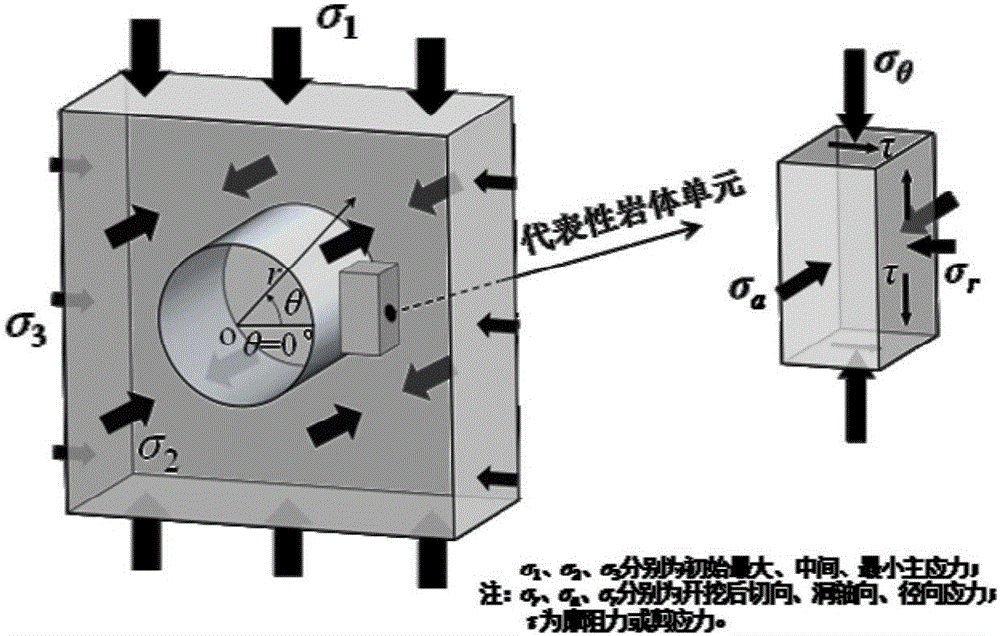

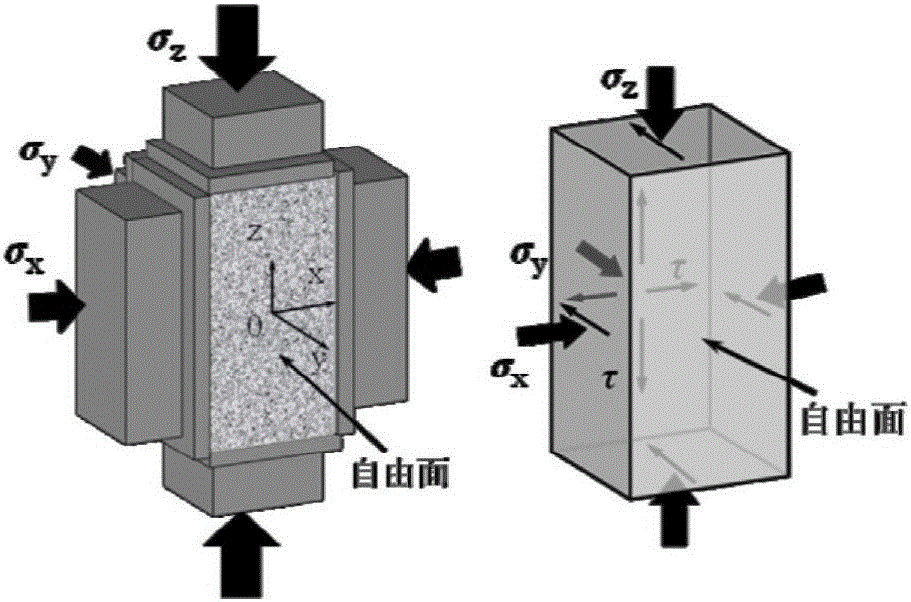

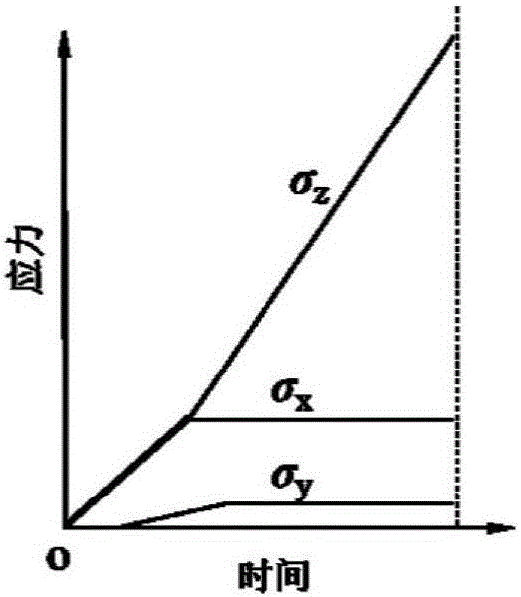

[0035]After the excavation of deep underground caverns, the stress state of the rock mass within a certain depth range near the boundary is as follows: figure 1 shown. The present invention adopts the true triaxial loading mode of one-sided air and five-sided force to simulate the above stress state, as figure 2 shown. Among them, the vertical stress σ z Simulated field tangential stress σ θ , horizontal stress σ x Axial stress σ of simulated site hole a , horizontal stress σ y Simulation site radial stress (distribution) σ r . With reference to the stress redistribution process under site excavation disturbance, formulate and adopt image 3 The test load path is shown. The hard and brittle rock specimens with good integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com