Tappet automatic comprehensive detection device

A comprehensive testing and equipment technology, applied in measuring devices, testing material hardness, optical testing flaws/defects, etc., can solve the problems of difficult structural shape detection, low testing efficiency, and high labor costs, avoiding manual testing and saving money. The effect of detection cost, time-saving and labor-saving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

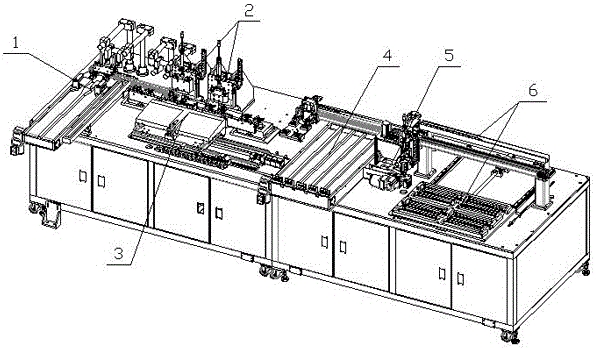

[0039] Embodiment: tappet automation comprehensive detection equipment, such as figure 1 As shown, it includes: a feeding mechanism 1, a detection mechanism 2, a station transfer mechanism 3, a marking device, a defective product classification mechanism 4, an oil injection device 5, a good product storage mechanism 6 and a control system.

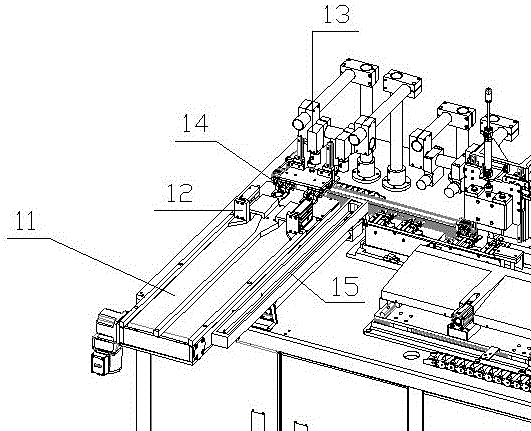

[0040] like image 3 As shown, the feeding mechanism 1 includes a feeding belt 11 , a whole material mechanism 12 , a pose judging device 13 , a mechanical jaw one 14 and a misplaced tappet recovery groove 15 . The whole material mechanism 12 is located at the end of the feeding belt 11, and the feeding belt 11 is a conveyor belt. The whole material mechanism 12 includes a single tappet drainage aisle, a material shifting block 121 and a material shifting cylinder 122, and the front side of the material shifting block 121 is slope-shaped. It is located on one side of the drainage passage, and the dialing block 121 is driven by the dial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com