A method for measuring the hydrogen evolution critical current density of steel bars in reinforced concrete structures

A critical current density, reinforced concrete technology, applied in the field of electrochemical treatment, can solve the problem of inability to accurately measure the hydrogen evolution critical current density of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

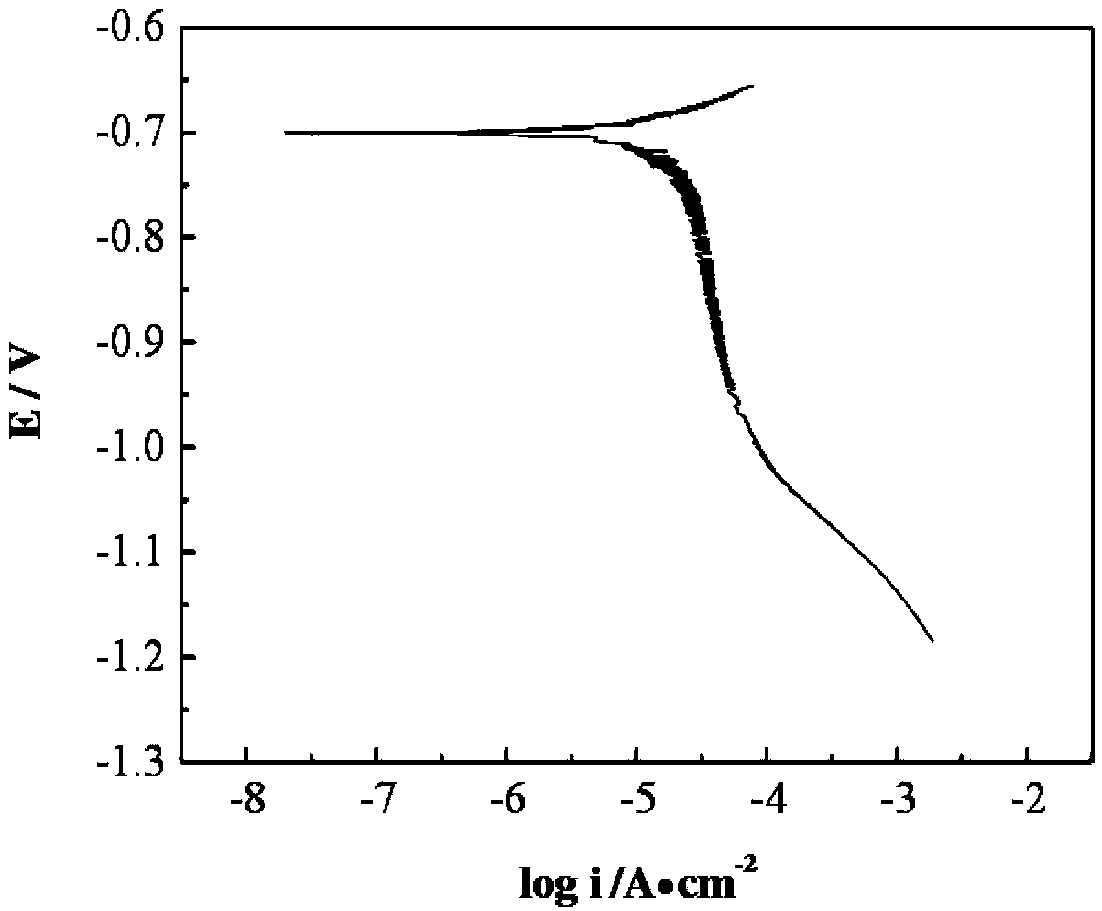

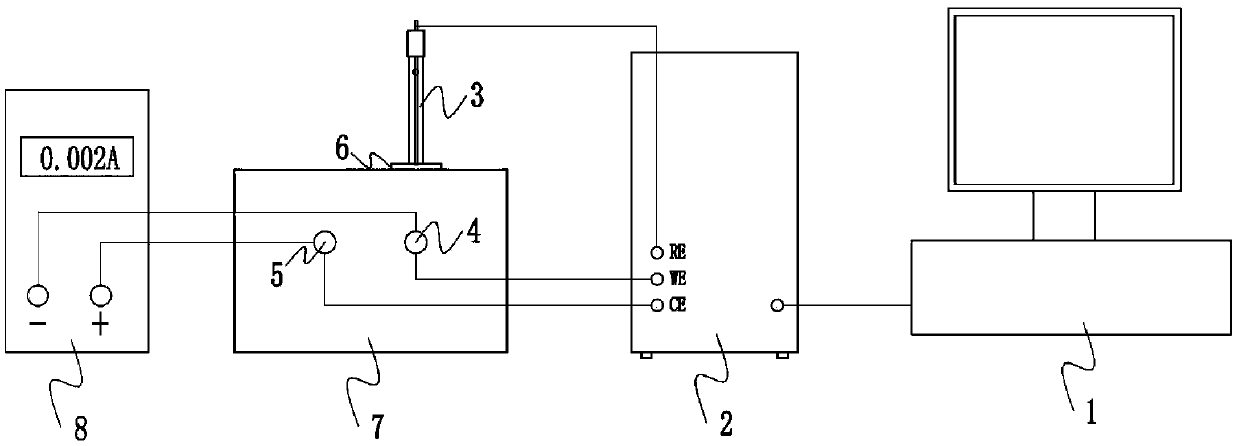

[0051] A reinforced concrete sample 7 is prepared in advance in the laboratory, and a steel bar 4 (ie, the working electrode) and a stainless steel rod 5 (ie, the counter electrode) are embedded in the sample 7 . Soak the sample 7 in pure water for one day to reduce the resistance of the test block, and then use the electrochemical workstation 2 (model is Refence600, produced by GAMRY Company of the United States) to test the potentiodynamic polarization curve of the steel bar. The test device is connected as follows: figure 1 shown.

[0052] During the test, the wetted sponge 6 is placed on the upper part of the sample 7, and then the saturated calomel reference electrode 3 is placed on the sponge 6 and corresponds to the middle position of the steel bar 4, so as to form a three-electrode test system Meanwhile, steel bar 4, stainless steel bar 5 and saturated calomel reference electrode 3 are connected with electrochemical workstation 2 respectively, steel bar 4, stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com