Material-saving silicon steel sheet

A technology of silicon steel sheet and cross-sectional shape, applied in the direction of magnetic material, inorganic material magnetism, magnetic core/yoke, etc. The problem of high iron loss value of sheet iron can achieve good economic and social benefits, improve magnetic properties, and low-loss magnetic induction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

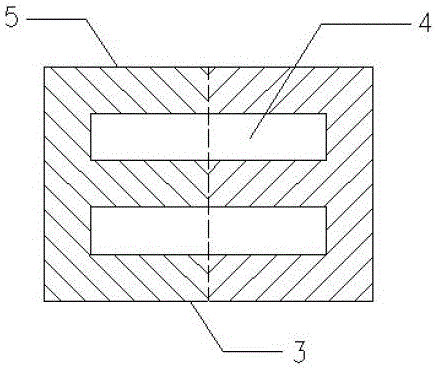

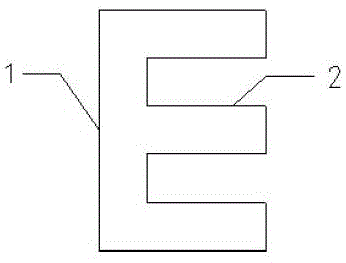

[0012] see figure 1 and figure 2 , the present invention relates to a material-saving silicon steel sheet, its cross-sectional shape is "day" shape, it includes an E-shaped structure 5 and an I-shaped structure 4, and the E-shaped structure 5 consists of a long side 1 and three short sides 2 Composition, the long side 1 of the E-shaped structure is twice the length of the short side 2, and the material of the silicon steel sheet is: C 0.06-0.08%, Si 2.6-3.2%, Mn 0.15-0.25%, Als 0.02-0.03 %, Co 0.2-0.25%, Cr 0.15-0.25%, Sn 0.05-0.1%, V 0.03-0.05%, Hf 0.015-0.025%, Ta 0.008-0.012%, B 0.002-0.003%, N 0.004-0.005%, Sc 0.02-0.03%, Gd 0.015-0.025%, Yb 0.01-0.02%, P≤0.05%, S≤0.0025%, and the rest is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com