a magnetic element

A technology of magnetic components and magnetic cores, applied in electrical components, parts of transformers/inductors, circuits, etc., can solve problems affecting performance and life, magnetic components without heat dissipation structures, secondary copper sheet windings and primary windings The relative position cannot be accurately positioned, etc., to achieve the effect of enhancing heat dissipation and flow, and realizing modular expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

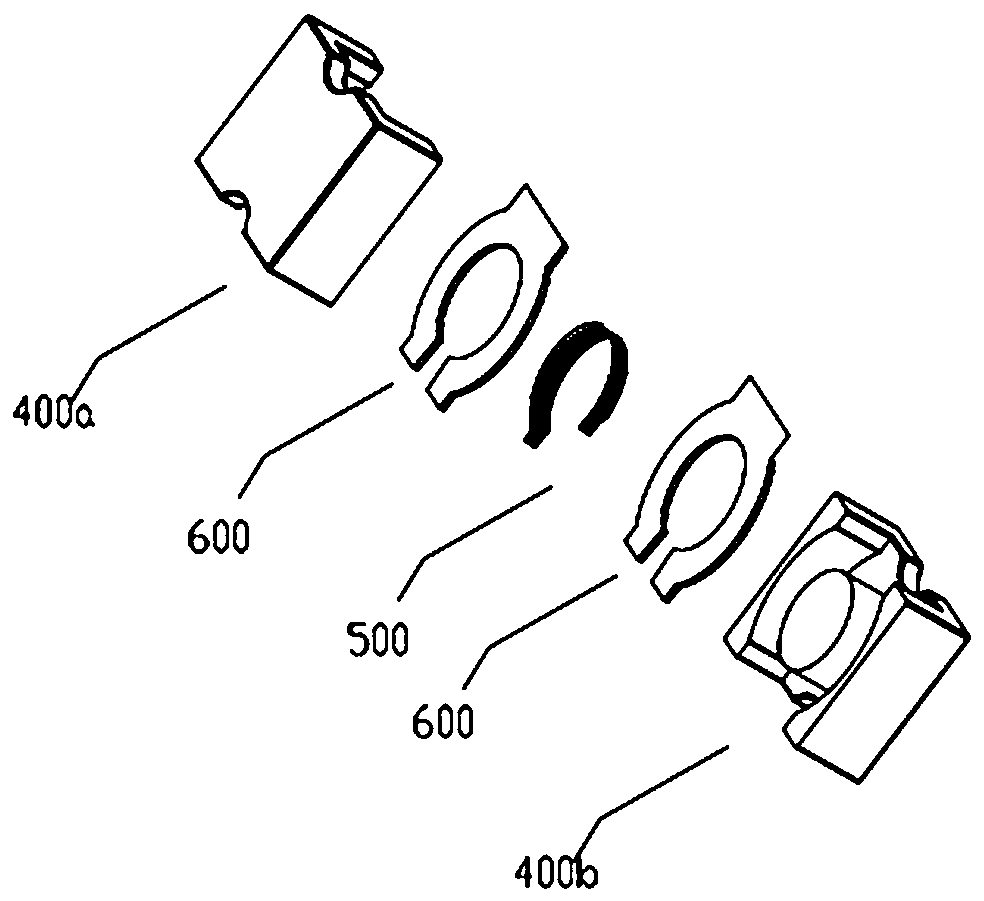

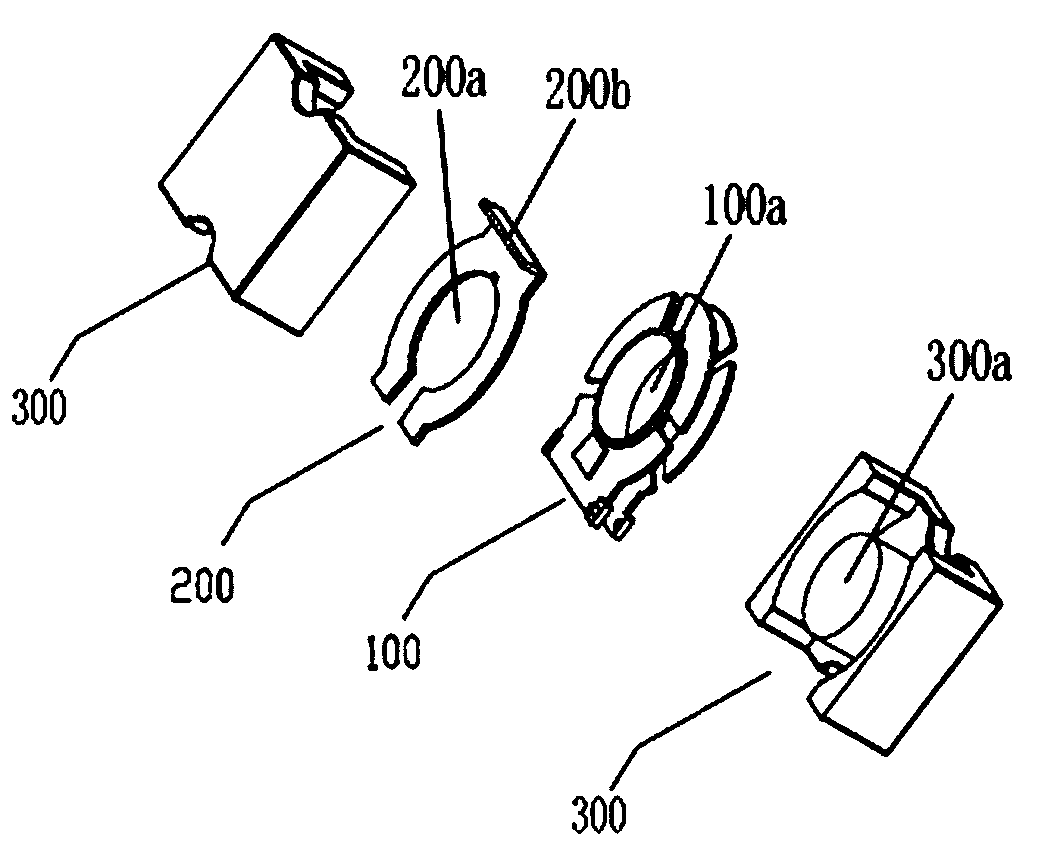

[0030] Such as figure 2 , 6 As shown in , 9 , the magnetic element proposed by the present invention includes: a winding bobbin 100 , a magnetic core group and a conductive winding 200 .

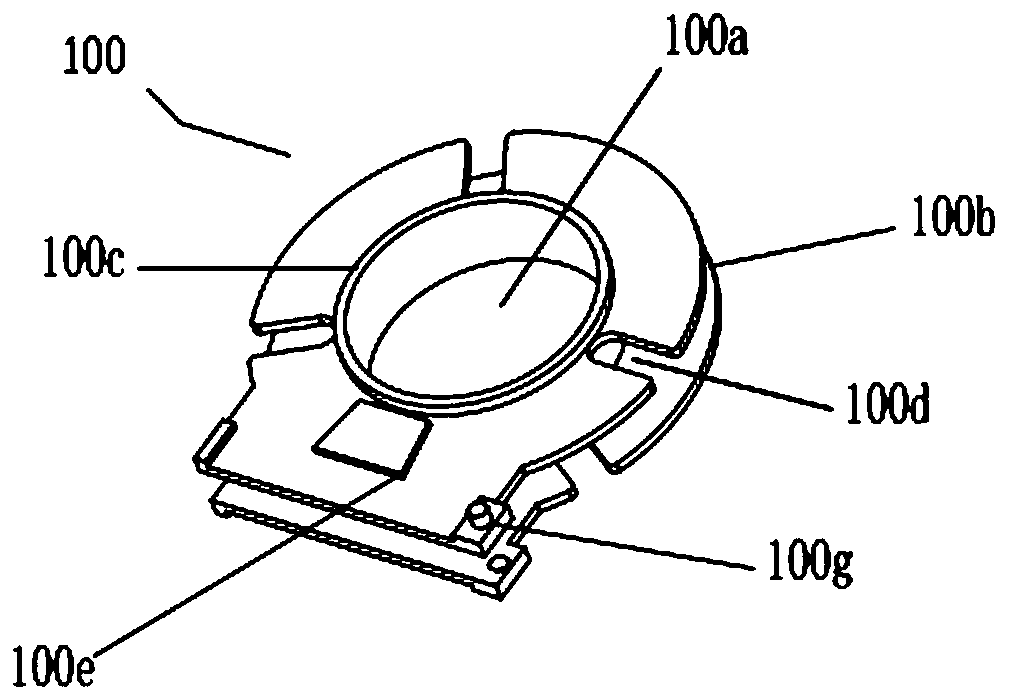

[0031] The main body of the bobbin 100 is a flat disc, and the center of the disc is provided with an installation channel 100a that runs through both ends of the disc. The side of the bobbin 100 is recessed inward to form a wire groove 100b, and the wire groove 100b surrounds the installation channel 100a. The setting of the outer ring and the wire groove 100b can realize the automatic winding process. The magnetic core group is composed of two butted magnetic cores 300 on the left and right, and at least one of the magnetic cores 300 is provided with a mounting post 300a that can be inserted into the mounting channel 100a. In actual application, the two magnetic cores 300 in the magnetic core group can be symmetrically arranged left and right, and the two magnetic cores 300 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com