Novel biochemical reactor and use method thereof

A biochemical reactor and reactor technology, applied in chemical instruments and methods, biological treatment devices, sustainable biological treatment and other directions, can solve the problems of constant optimization and regulation of equipment, large demolition and construction, and inconvenient transformation of reactor layout. To achieve the effect of saving operating costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

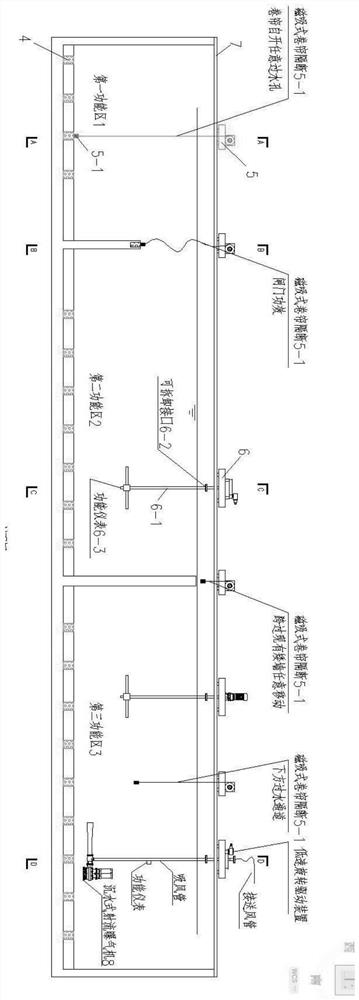

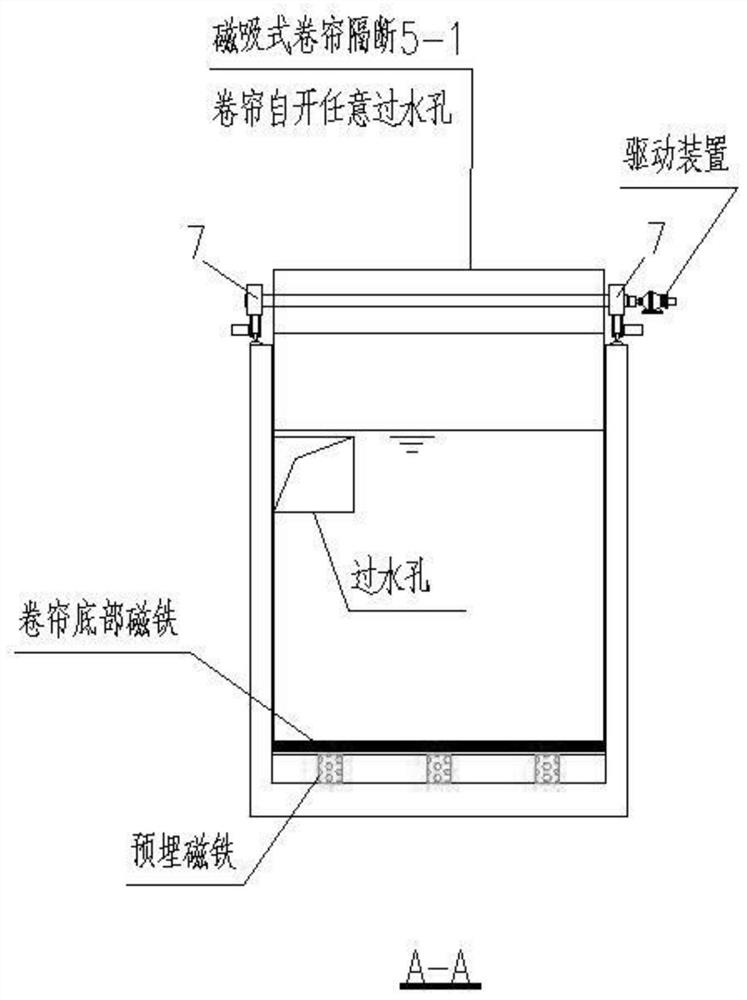

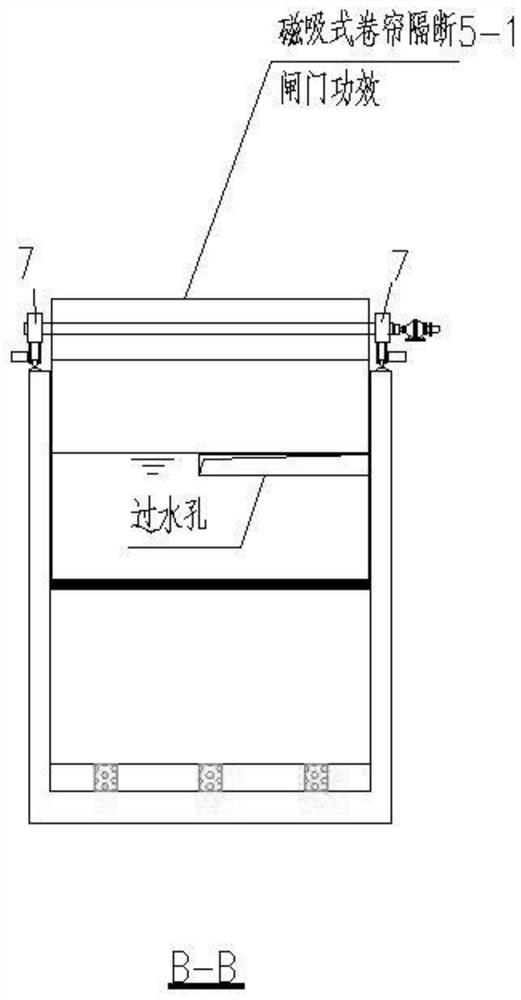

[0032] Such as figure 1 As shown, it is a novel biochemical reactor provided by the present invention, the reactor is a rectangular pool body structure, and the pool body is divided into the first functional area 1, the second functional area 2, the third functional area 3 and the Nth functional area, The number of functional areas is adjusted according to actual process requirements. The second functional area 2 is a precise mixing area with mobile functional instrument detection and linkage control, and the third functional area 3 is precise aeration with mobile functional instrument detection and linkage control. area; the pre-embedded magnets 4 are evenly and equidistantly arranged on the bottom of the pool or on the low wall in the pool, and the magnets can be in various shapes such as blocks and strips, such as Figure 2-3 As shown, the upper part of the pool body is provided with a track 7 and a longitudinal track trolley 5, and the longitudinal track trolley 5 slides l...

Embodiment 2

[0041] This embodiment provides a method for using the novel biochemical reactor provided in Embodiment 1, comprising the following steps:

[0042] 1) The longitudinal track trolley 5 moves longitudinally on the upper part of the reactor pool body along the track 7, and enters the first functional area 1, and the counterweight magnet 5-2 and the embedded magnet 4 attract each other to ensure that the magnetic roller blind is in a vertical state , to form a partition, and the roller blind can be retracted by rotating the roller blind by the driving device. After the roller blind is fully retracted, it can step over the concrete low wall in the pool and move freely to any position in the pool body. When the roller blind is lowered halfway, it can form the lower part of the roller blind Water channel, channel height adjustable;

[0043] 2) The roller blind is rotated by the driving device to retract all the roller blinds, and enters the second functional area 2 across the low wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com