A Modular Local Resonance Type Phononic Crystal Vibration Isolation Pad

A technology of local resonance and phononic crystals, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of small period number of periodic materials, limited working space, and insignificant vibration isolation effect, etc. Achieve outstanding vibration isolation effect, wide application range, and realize the effect of modular expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

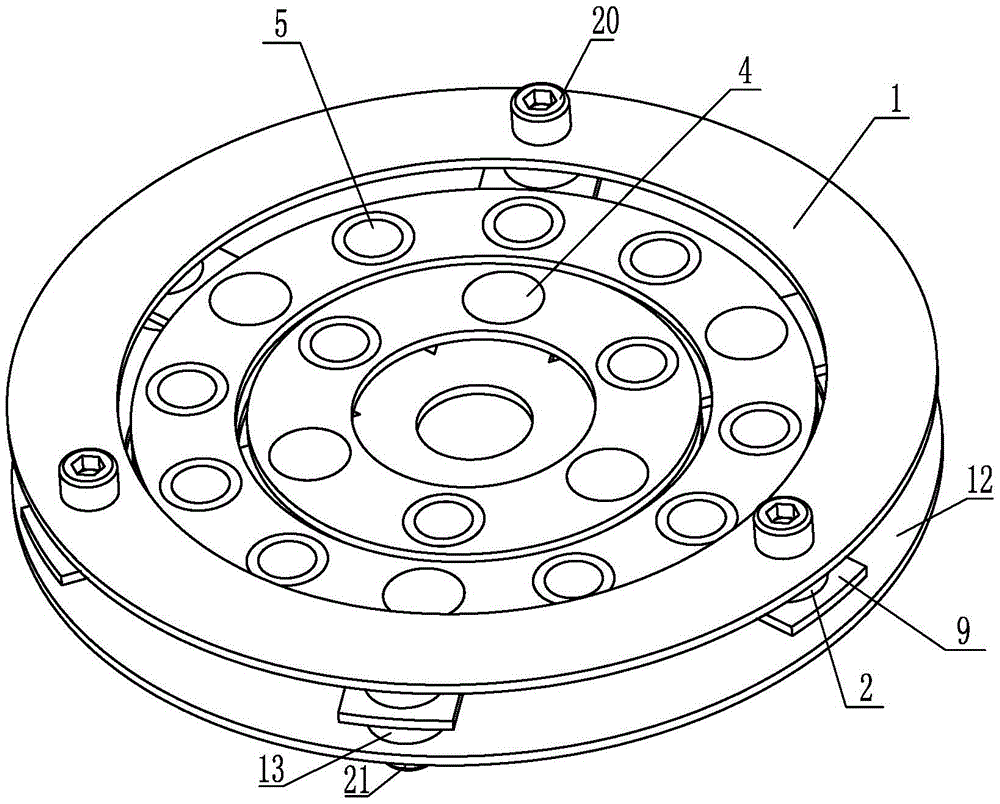

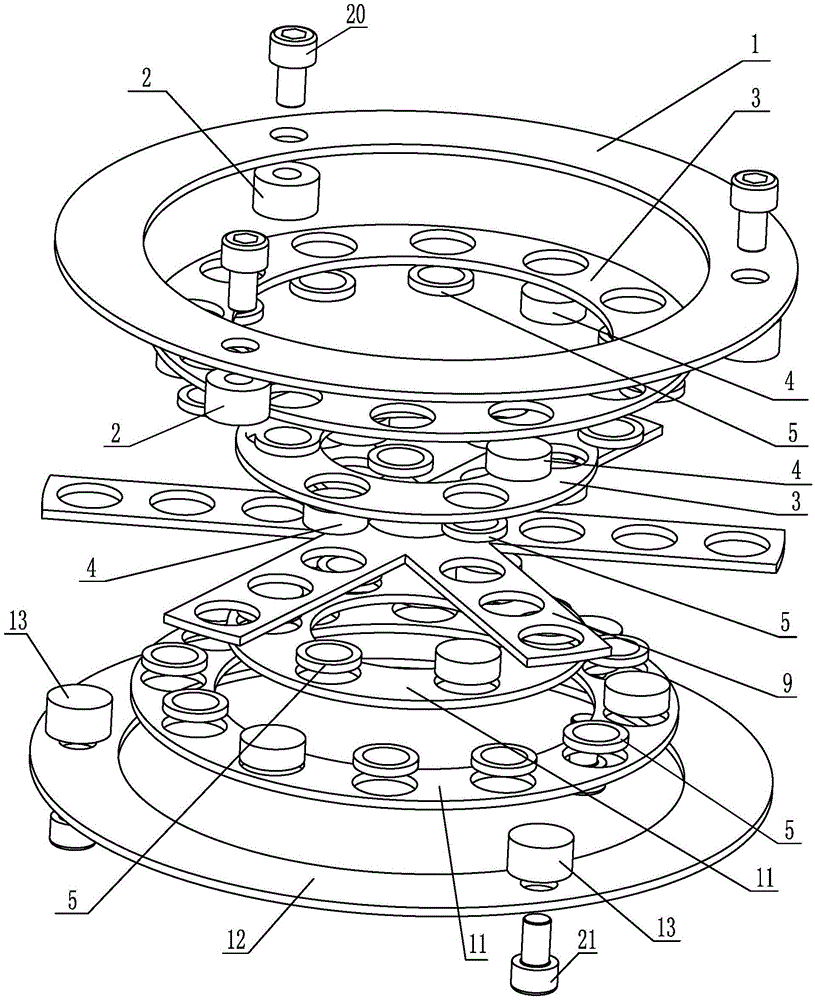

[0015] Specific implementation mode one: combine Figure 1-Figure 3 Explain that a modular local resonance type phononic crystal vibration isolation pad in this embodiment includes a vibration input support 1, a main body support frame 9, a vibration output support 12, a plurality of vibration input support connecting columns 2, multiple A vibration output support connects the cylinder 13 and the N-level local resonance type phononic crystal component, wherein N is a positive integer, and N≥2;

[0016] The vibration input support 1 is located above the vibration output support 12, between the vibration input support 1 and the vibration output support 12, N-level local resonance type phononic crystal components are arranged sequentially from outside to inside, and the N-level local resonance The type phononic crystal components are arranged between the N-1 level local resonance type phononic crystal components;

[0017] Each level of local resonance type phononic crystal assem...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 and figure 2 Explain that the vibration input support 1 and the vibration output support 12 of this embodiment are both circular structures, and the vibration isolation upper support 3 and the vibration isolation lower support 11 in each level of local resonance type phononic crystal assembly are both It is a circular structure. Such an arrangement has a simple structure and a reasonable design, which is beneficial to the optimal layout of the multi-level local resonance type phononic crystal. Others are the same as in the first embodiment.

specific Embodiment approach 3

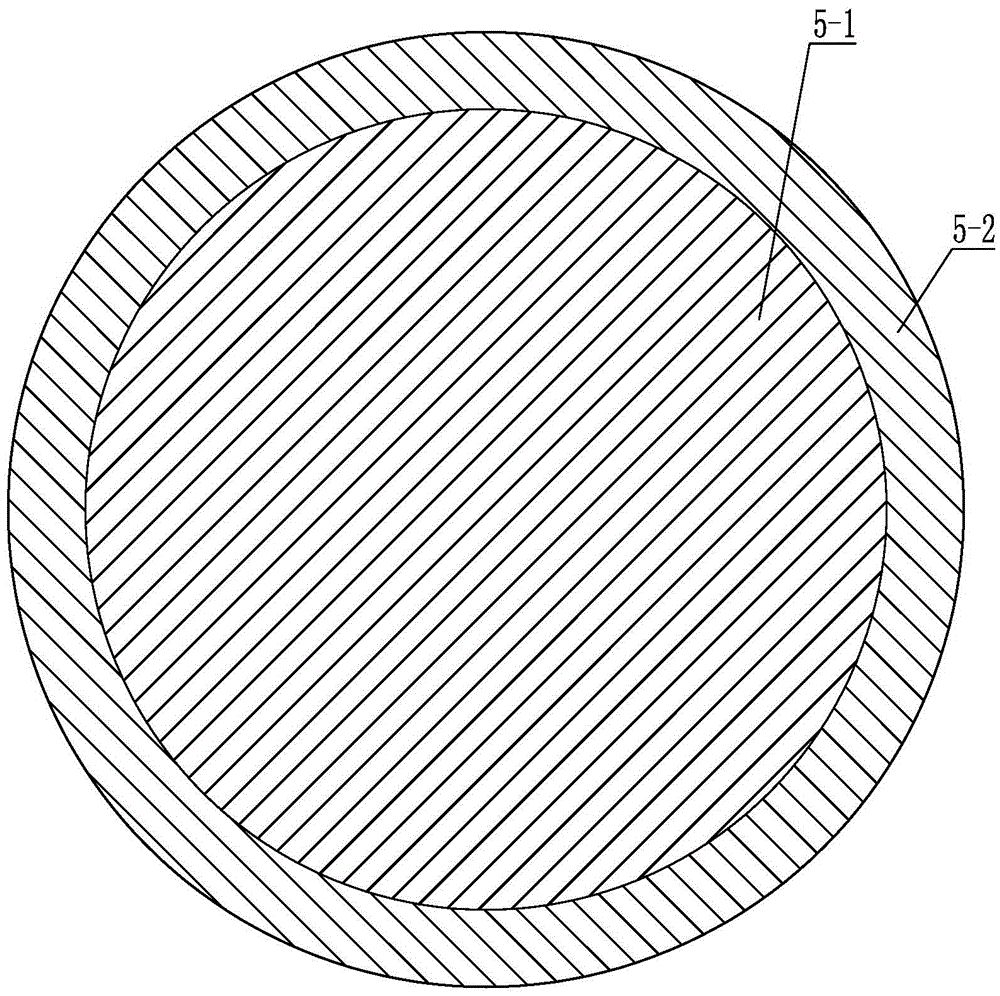

[0023] Specific implementation mode three: combination figure 2 and image 3 Note that the vibration-isolation upper support 3 and the vibration-isolation lower support 11 of each level of local resonance type phononic crystal components in this embodiment are respectively processed with the number of local resonance type phononic crystal local oscillators 5 arranged respectively. A plurality of first circular through holes are consistent, and the local resonance type phononic crystal local oscillator 5 is glued in the first circular through holes. With such setting, the connection is reliable and the structure is stable and reasonable. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com