Anti-overheating CSP (chip scale package) fluorescent diaphragm mould pressing device and anti-overheating CSP fluorescent diaphragm mould pressing method

A fluorescent film, anti-overheating technology, used in lighting devices, light sources, lighting and heating equipment, etc., can solve problems such as overheating of fixtures and melting of fluorescent film, and achieve the effects of easy control, improved service life, and reduced impact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

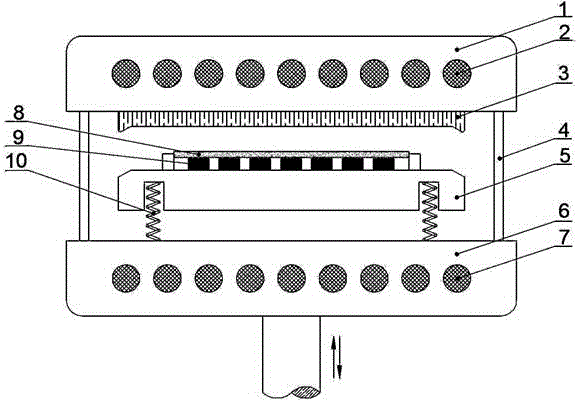

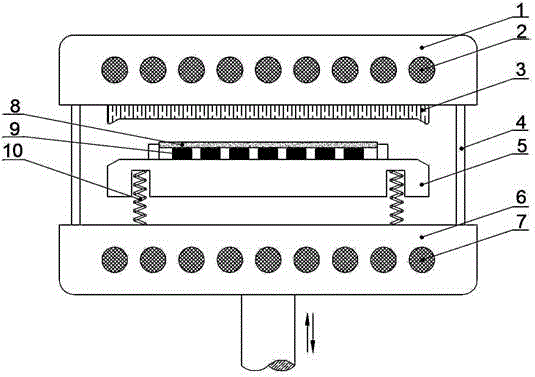

[0054] In the device adopted in this embodiment, the elastic supporting structure is a spring leaf, and the stiffness of the spring leaf along the die direction is 10N / cm; 3% of the surface area, the contact between the spring leaf and the lower die main body 6 is a line contact, and the contact area is 3% of the upper surface area of the lower die main body 6; The contact area of the upper surface of 6 is 95% of the lower bottom surface area of lower fixture 5.

[0055] The above-mentioned overheating preventing CSP fluorescent film molding device is used to realize the molding of the CSP fluorescent film.

[0056] (1) The heating devices of the upper and lower dies are activated, the dies are preheated, and the temperature is maintained at 78°C;

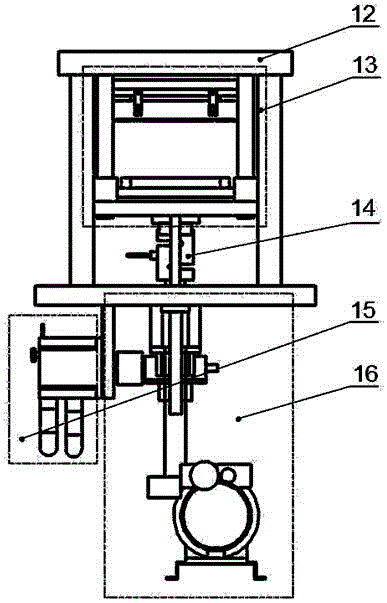

[0057] (2) The upper fixture 3 and the lower fixture 5 are controlled and separated by the feeding device 16, and the lower fixture 5 and the lower die body 6 are separated by 1mm through the elastic support structure;

[0...

Embodiment 2

[0065] In the device adopted in this embodiment, the elastic support structure is a spring leaf, and the stiffness of the spring leaf along the die direction is 25N / cm; 5% of the surface area, the contact between the spring leaf and the lower die main body 6 is a line contact, and the contact area is 5% of the upper surface area of the lower die main body 6; The contact area of the upper surface of 6 is 90% of the lower bottom surface area of lower fixture 5.

[0066] The above-mentioned overheating preventing CSP fluorescent film molding device is used to realize the molding of the CSP fluorescent film.

[0067] (1) The heating devices of the upper and lower dies are activated, the dies are preheated, and the temperature is maintained at 82°C;

[0068] (2) The upper fixture 3 and the lower fixture 5 are controlled and separated by the feeding device 16, and the lower fixture 5 and the lower die body 6 are separated by 10mm through the elastic support structure;

[006...

Embodiment 3

[0076] In the device adopted in this embodiment, the elastic support structure is a spring leaf, and the stiffness of the spring leaf along the die direction is 20N / cm; 5% of the surface area, the contact between the spring leaf and the lower die main body 6 is a line contact, and the contact area is 5% of the upper surface area of the lower die main body 6; The contact area of the upper surface of 6 is 93% of the lower bottom surface area of lower fixture 5.

[0077] The above-mentioned overheating preventing CSP fluorescent film molding device is used to realize the molding of the CSP fluorescent film.

[0078] (1) The heating devices of the upper and lower dies are started, the dies are preheated, and the temperature is maintained at 80°C;

[0079] (2) The upper fixture 3 and the lower fixture 5 are controlled and separated by the feeding device 16, and the lower fixture 5 and the lower die body 6 are separated by 8 mm through the elastic support structure;

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com