Aluminum-casing battery module assembly line and assembling process

A technology of aluminum shell battery and assembly line, which is applied in the direction of battery assembly machine, secondary battery manufacturing, sustainable manufacturing/processing, etc., which can solve the problems of low production efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

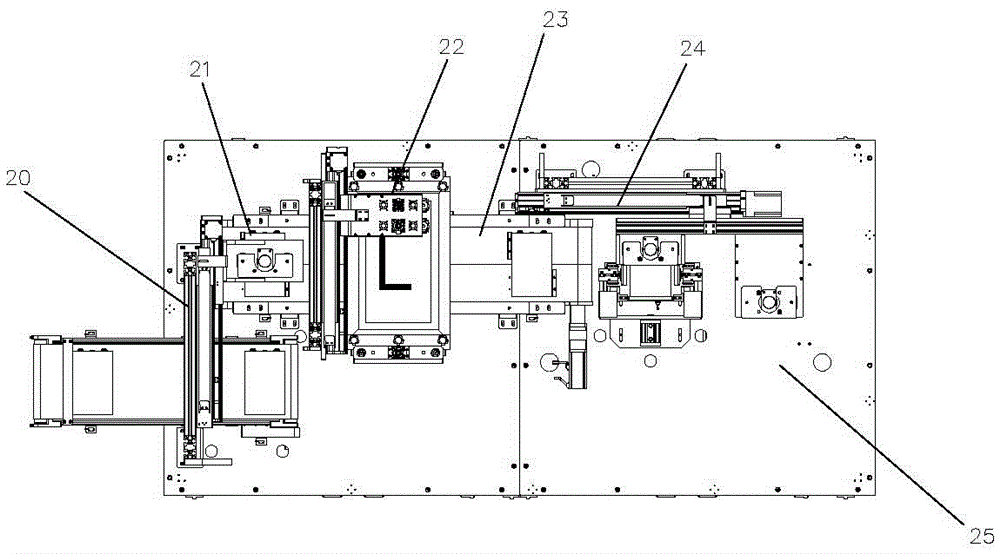

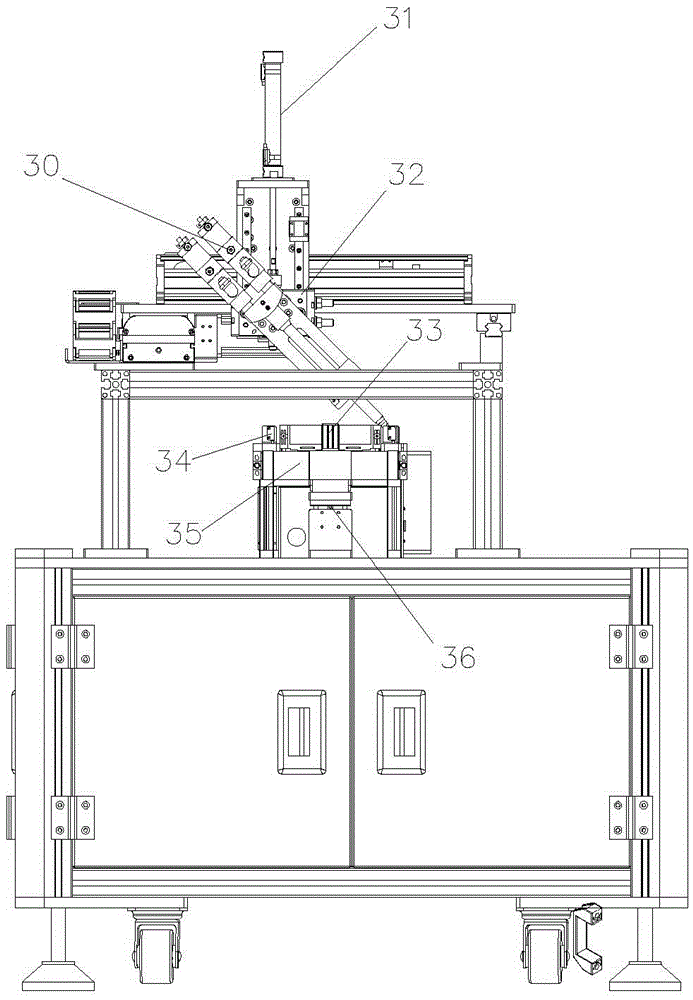

[0037] The aluminum case battery module assembly line of the present invention includes an automatic cleaning and sorting machine for voltage internal resistance testing, an aluminum case battery screen printing machine, a glue dispenser inside the heat conduction case, and a laser coding machine for the heat conduction case, which are sequentially set up according to the production process Dispensing machine outside the heat conduction shell, double-speed line of aluminum shell battery module and battery pack assembly line.

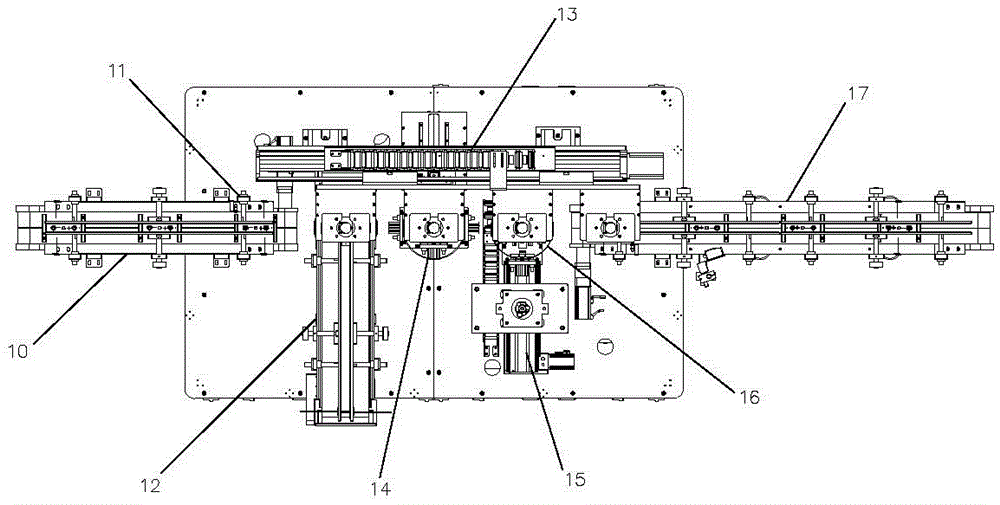

[0038] Such as figure 1 As shown, the automatic cleaning and sorting machine for voltage internal resistance test includes a loading pull belt 10, a code scanning gun 11, a plasma cleaning machine 14, a voltage internal resistance tester 16, a linkage manipulator 13 and a feeding pull belt 17; The code scanning gun 11 is set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com