Breaker assembling system and assembling method thereof

A circuit breaker assembly and circuit breaker mechanism technology, applied in the direction of switchgear, electrical components, etc., can solve the problems of non-adjustable, lack of detection data, flatness out-of-tolerance parallelism, etc., to improve assembly efficiency, ensure assembly quality, improve The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

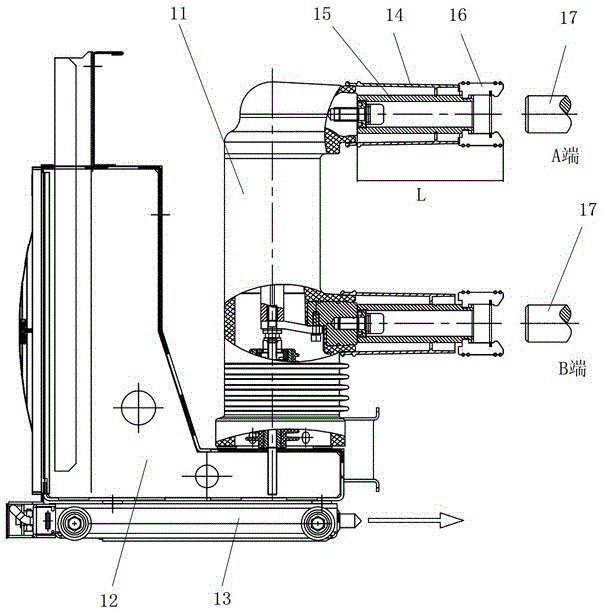

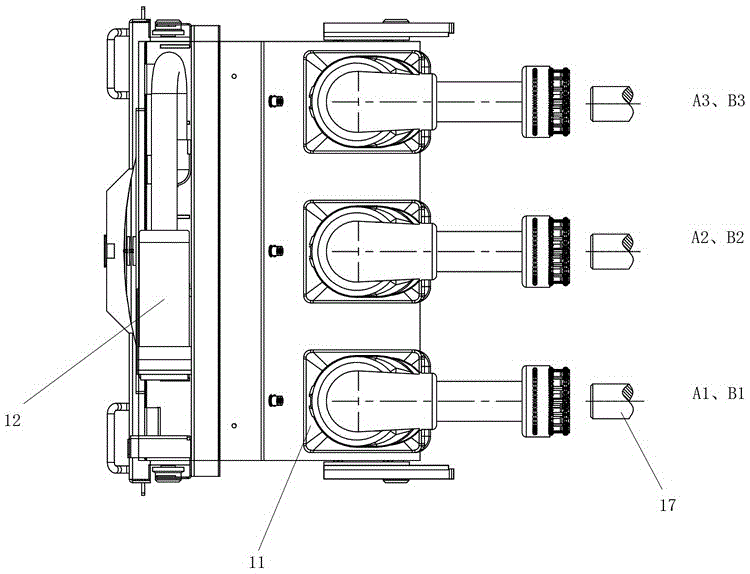

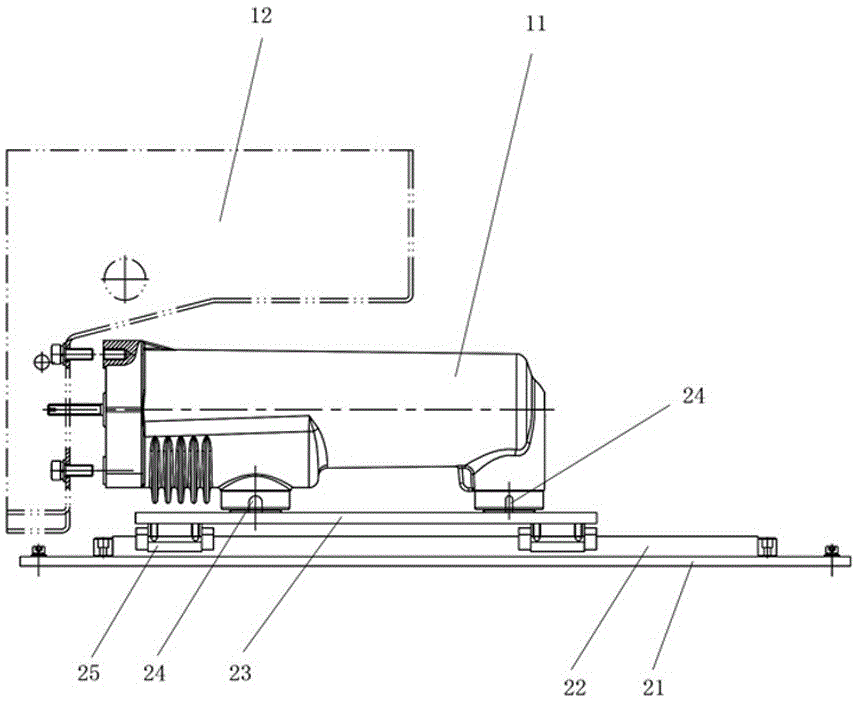

[0037] Such as Figure 4 to Figure 12 As shown, the circuit breaker assembly system of this embodiment includes a lifting platform 2, an assembly platform 3 slidingly arranged on the lifting platform 2, a first feeding device 4 for loading and unloading poles 11, and a circuit breaker mechanism. 12 The second feeding device 5 for loading and unloading, the detection device 6 for detecting the flatness of the outlet end surface of the pole 11, and the display device 7 for displaying the detection results. The number of assembly plates 3 and poles 11 is the same, and each assembly platform The board 3 is provided with a positioning part 31 for locating the outlet hole of the pole 11. The detection device 6 has the same number as the assembly table 3 and is installed on the assembly table 3 in one-to-one correspondence. The display devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com