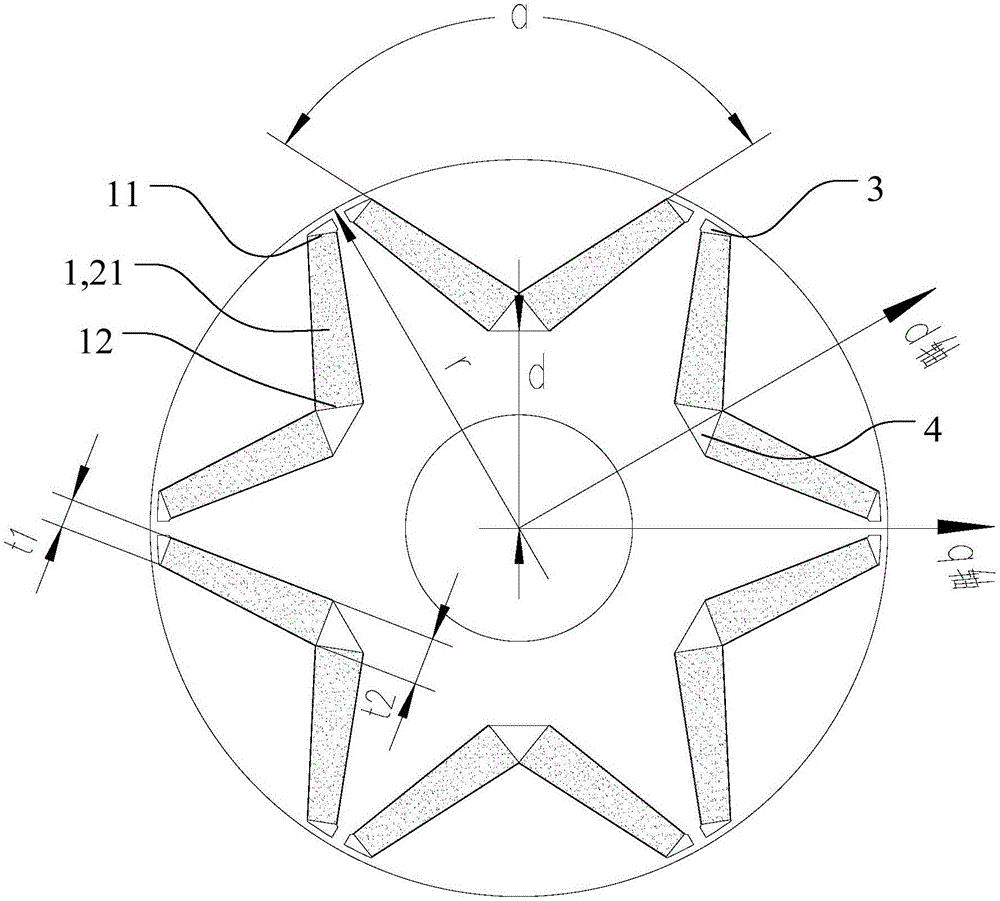

Rotor and permanent magnet motor

A rotor and permanent magnet technology, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of high harmonic content of air gap magnetic density and small reluctance torque, so as to reduce harmonic content and reduce harmonics. losses, increased efficiency and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The air gap main magnetic field of a permanent magnet motor is generated by a permanent magnet, and the magnetic density generated by the permanent magnet is positively correlated with its thickness in the magnetization direction. The larger the thickness of the permanent magnet, the larger the air gap magnetic density. Therefore, by changing The thickness of the permanent magnet in the magnetization direction can improve the air-gap flux density waveform, thereby reducing the harmonic content of the air-gap flux density, reducing harmonic loss, and improving the efficiency of the motor using it.

[0027] Based on this, the present invention provides a rotor, which includes a rotor core 2 and a permanent magnet 1 disposed in the rotor core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com