Halbach birotor self-sliding wide range speed regulation permanent magnet hub motor for electric vehicle

A technology for in-wheel motors and in-wheel motors, applied in electric vehicles, motors, electric components, etc., can solve the problems of difficulty in improving efficiency, high transmission energy consumption, low speed range, etc., so as to reduce thickness and energy loss and improve constant speed. Power capability, the effect of increasing the speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

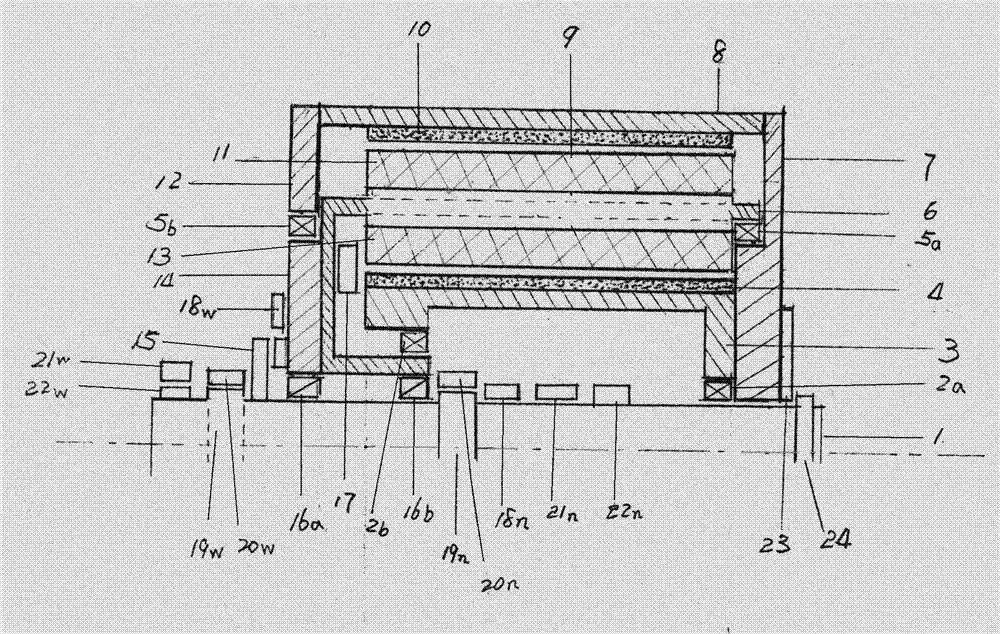

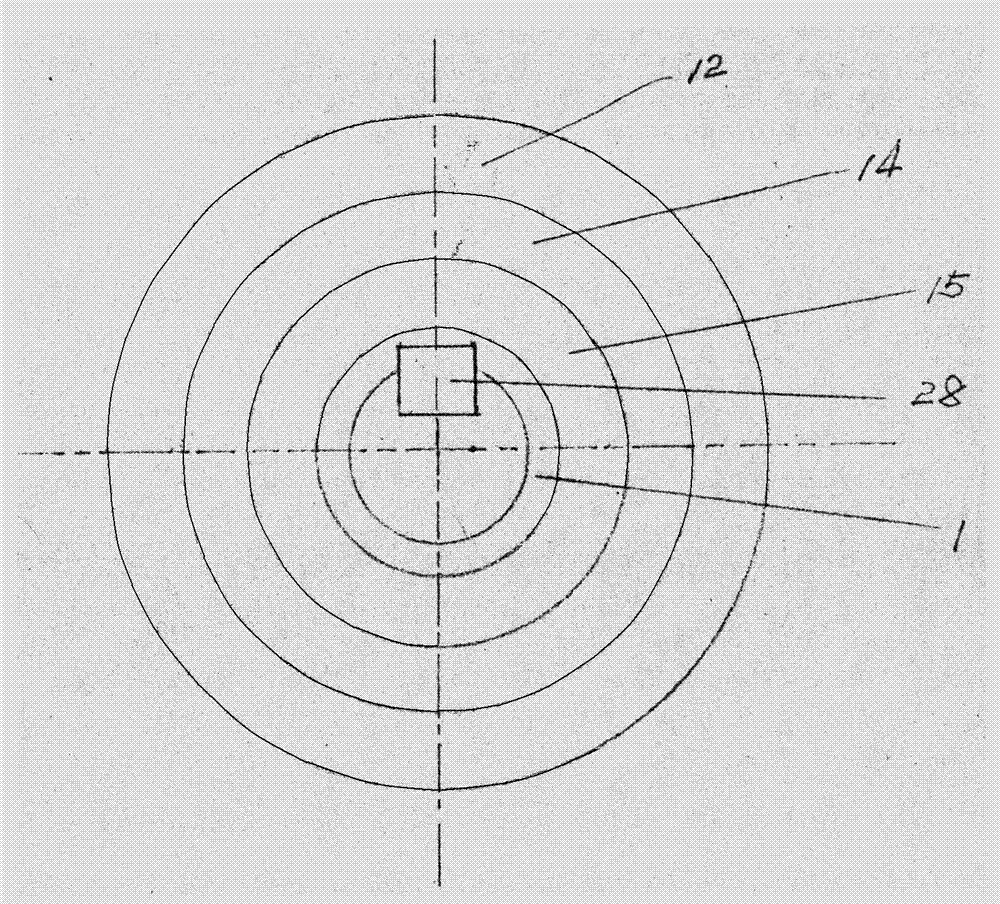

[0021] The present invention will be further described below in conjunction with all accompanying drawings: the wheel hub motor for electric vehicles described in this embodiment has the following components:

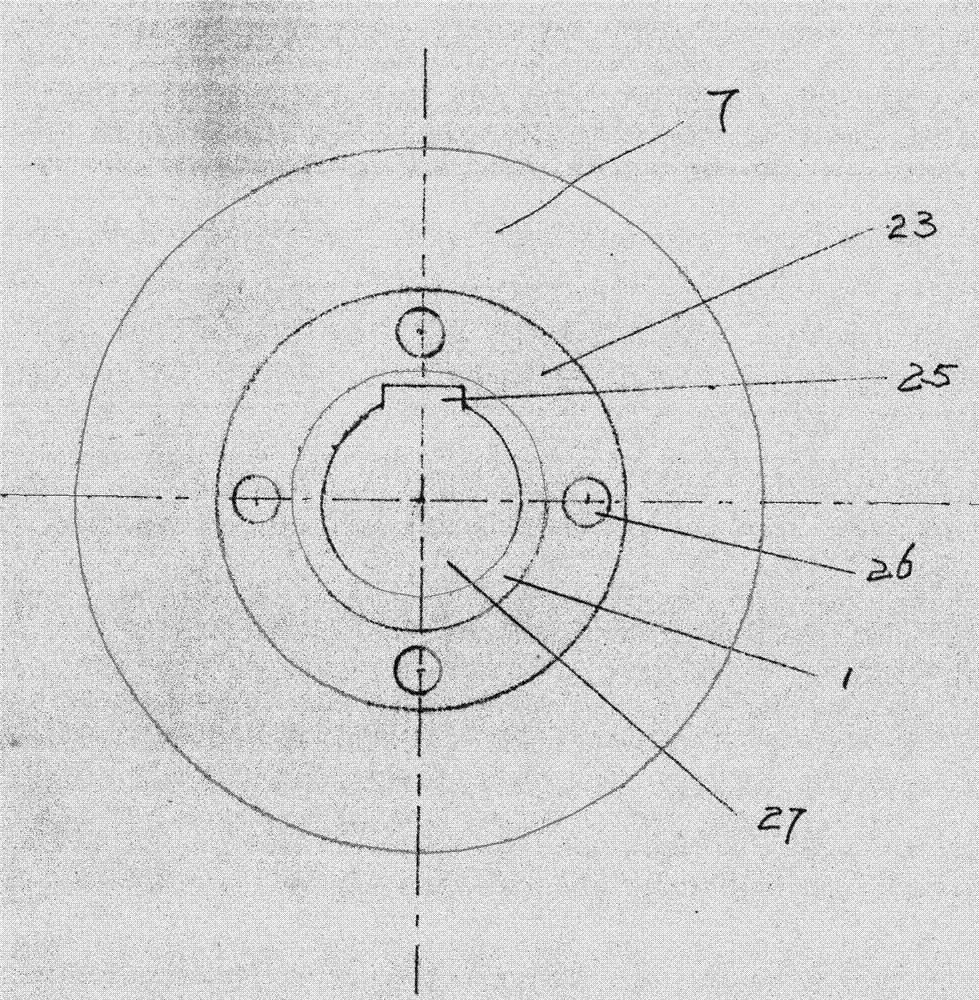

[0022] 1. Assemble the central shaft part, which includes the hollow shaft (1), keyway (25), connecting hub bolts (26), wiring sleeve (28), positioning device (24), hollow shaft (1) inner cavity (27) There is a keyway (25) and a wiring sleeve (28) inside, the keyway (25) is closely matched with the keyway on the wheel shaft of the automobile, or a spline fit can be used, and the wiring sleeve (28) is on the other end of the hollow shaft (1) It is as wide as the keyway (25), and there are various connecting wires in the wiring sleeve (28). ,convenient.

[0023] 2. Double rotor structure and Halbach array part, which includes inner rotor (3), outer rotor (8), inner rotor Halbach magnet (4), outer rotor Halbach magnet (10), right end cover (7), left end cover ( 12), inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com