Heat radiating device

A technology of heat dissipation device and thermal fluid, which is applied in the field of communication, can solve problems such as not found, and achieve the effect of increasing battery life and rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

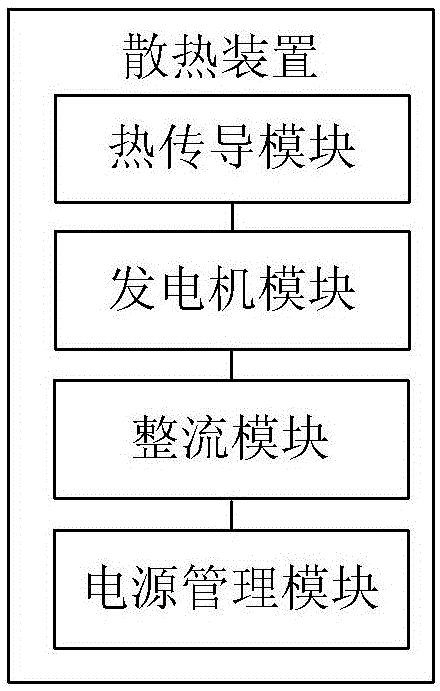

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

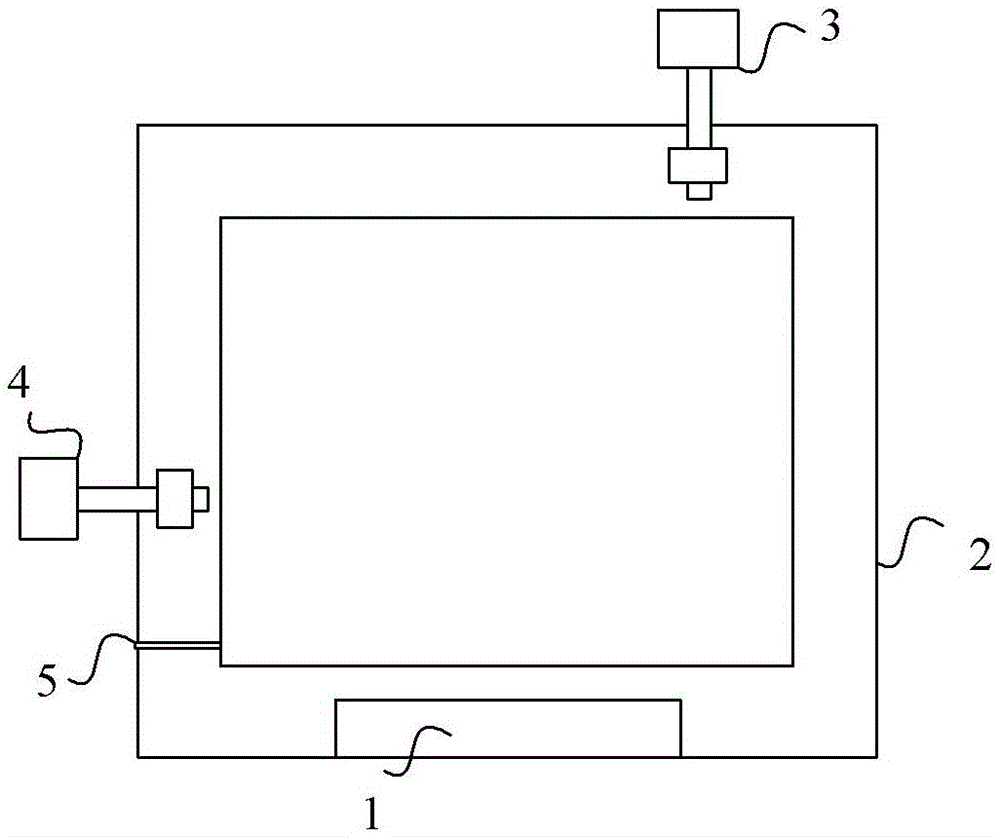

[0040] In this embodiment, the heat conduction module and the generator module are nested together to form the core components of the device, such as figure 2 As shown, it includes: thermal fluid 1, closed copper tube 2, generators 3 and 4, gravity check shrapnel 5.

[0041] The heat conduction liquid storage box of the heat conduction module is made of copper, which is in full contact with the heating area in the portable terminal product, and the contact gap is filled with silver-containing silicone grease to ensure the contact area and heat conduction efficiency.

[0042] When the thermal fluid 1 absorbs the heat emitted by the portable terminal product, the volume expands and flows in the direction indicated by the arrow, pushing the blades of the generator 3 to rotate to generate electric energy. The thermal fluid 1 flows through the generator 3 and continues to flow along the copper tube, using its own gravitational potential energy to push the blades of the generator 4...

Embodiment 2

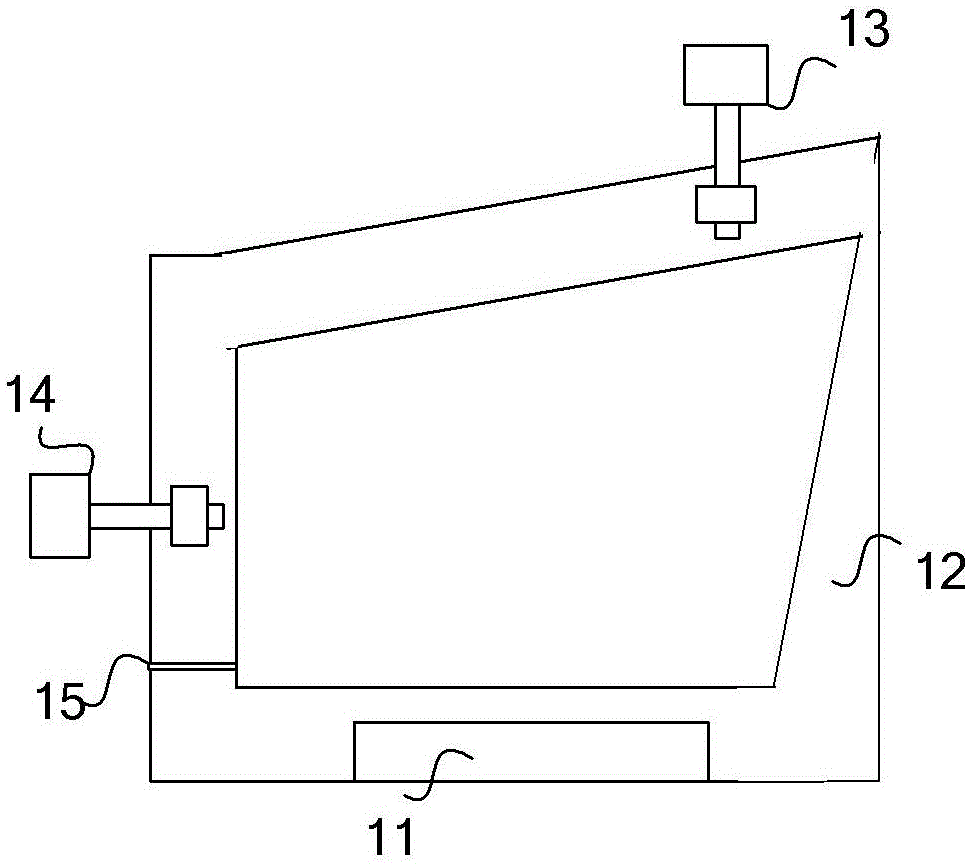

[0044] A heat dissipation device applicable to portable terminal products in this embodiment includes: a heat conduction module, a permanent magnet DC generator, a power management module and a battery module. The heat conduction module and the miniature permanent magnet DC generator are nested together to form the core part of the cooling device of this embodiment, and the electric energy generated by waste heat is used to charge the battery through the power management chip.

[0045] The module composed of heat conduction module and permanent magnet DC generator nesting is as follows: image 3 shown. Wherein, 11 is the thermal fluid methyl silicone oil, 12 is the closed copper tube, 13 and 14 are the permanent magnet DC generators, and 15 is the gravity check shrapnel. The thermal fluid storage box of the thermal conduction module is made of copper, which is in full contact with the heating area inside the portable terminal product, and the contact gap is filled with silver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com