Milking device

A technology of cleaning device and monitoring device, applied in milking device, milk container, cleaning method using liquid, etc., can solve the problems of lack of control, insufficient control of cleaning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

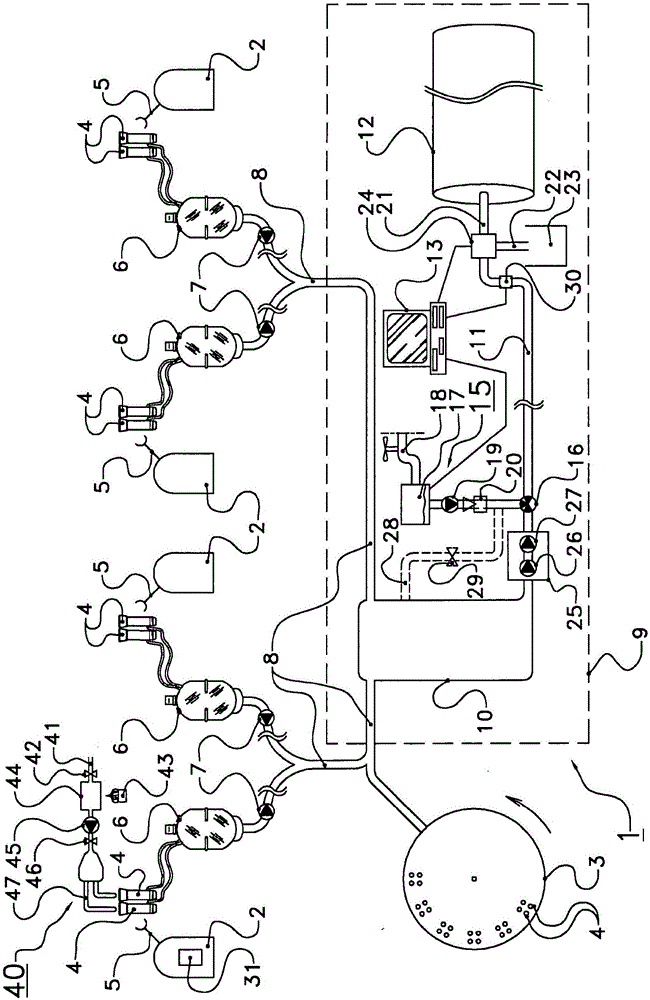

[0034] figure 1 A height schematic view of a milking system 1 according to the invention is shown. Here, the milking system 1 also includes a carousel 3 plus four milking robot devices 2 . Each milking robot device 2 has a teat cup 4 and a clamp arm 5 to allow the teat cup to be attached to the teat of a dairy farm animal. In addition, there are in each case: a milking glass 6 for collecting milk from the milking operation; and a milk pump 7 for pumping milk through a milk duct 8 to a milk storage system 9 , The milk storage system 9 comprises a temporary milk storage container 10 connected to a milk storage tank 12 via a main milk conduit 11 .

[0035] Reference numeral 13 denotes a control unit, reference numeral 15 denotes a pressurized liquid supply source connected to the main milk line 11 through a second selection means 16, a boiler 17, a water line supply source 18, a pump 19 and flow meter 20 .

[0036] Furthermore, reference numeral 21 designates a first discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com