Absorbent core

A technology for absorbent cores and absorbent products, applied in the field of absorbent cores, can solve the problems of not having, not providing comfort and safety protection, etc., and achieve the effects of good fit, good absorption capacity, and high absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

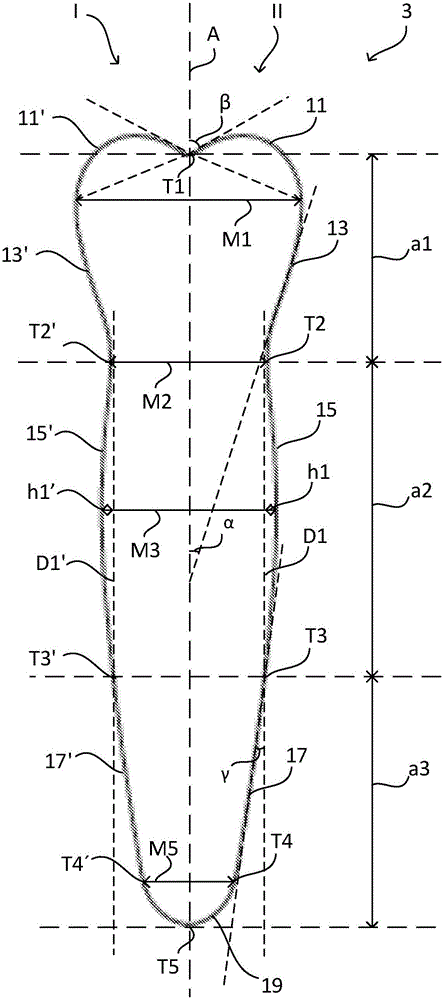

[0035] figure 1 is a schematic view of an absorbent core 3 according to the invention, seen from above. The core 3 comprises absorbent material and superabsorbent material having absorbent properties. The core has a first extension in the longitudinal direction and a second extension in the transverse direction. The core has a longitudinal centerline A extending through the core. The longitudinal centerline A is located between the first longitudinal section I and the second longitudinal section II. The first and second longitudinal sections I, II are symmetrical about a longitudinal centerline A. The core has a head a1 , a middle part a2 and a rear a3 extending longitudinally of the core 3 from the front of the core 3 to the rear of the core 3 . The longitudinal extension of the head a1 is about 1 / 4 of the longitudinal extension of the core 3, the longitudinal extension of the middle part a2 is about 1 / 2 of the longitudinal extension of the core 3 and the longitudinal exten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com