Method and device for treating an organic effluent

A discharge and equipment technology, which is applied in the field of equipment for treating emulsion, highly colloidal water and/or liquid sludge, can solve problems such as inability to remove, and achieve the effect of simple equipment, less operation restrictions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

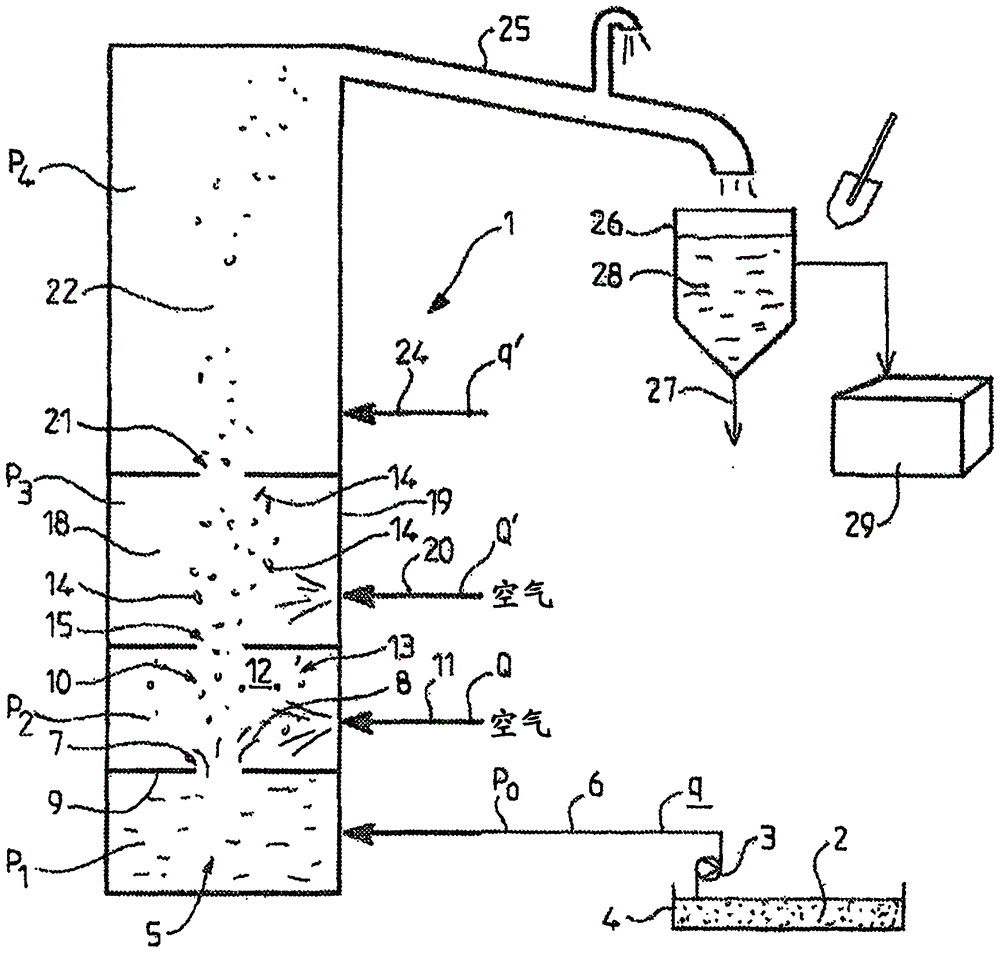

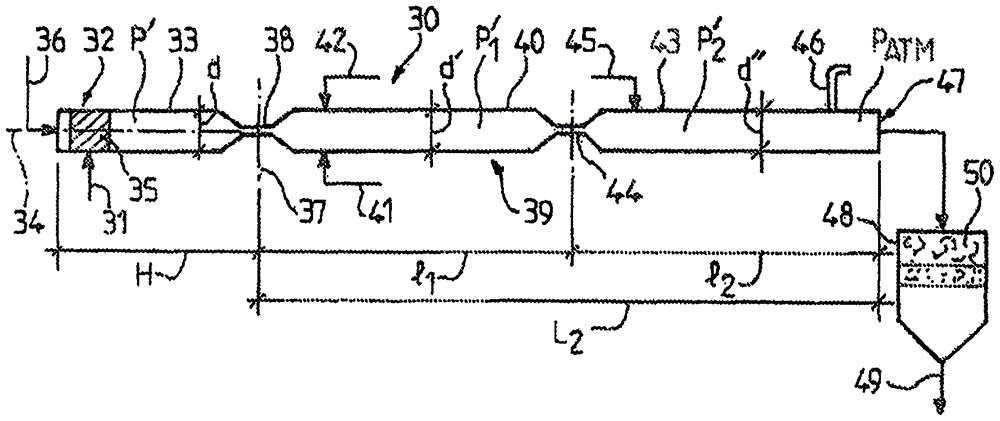

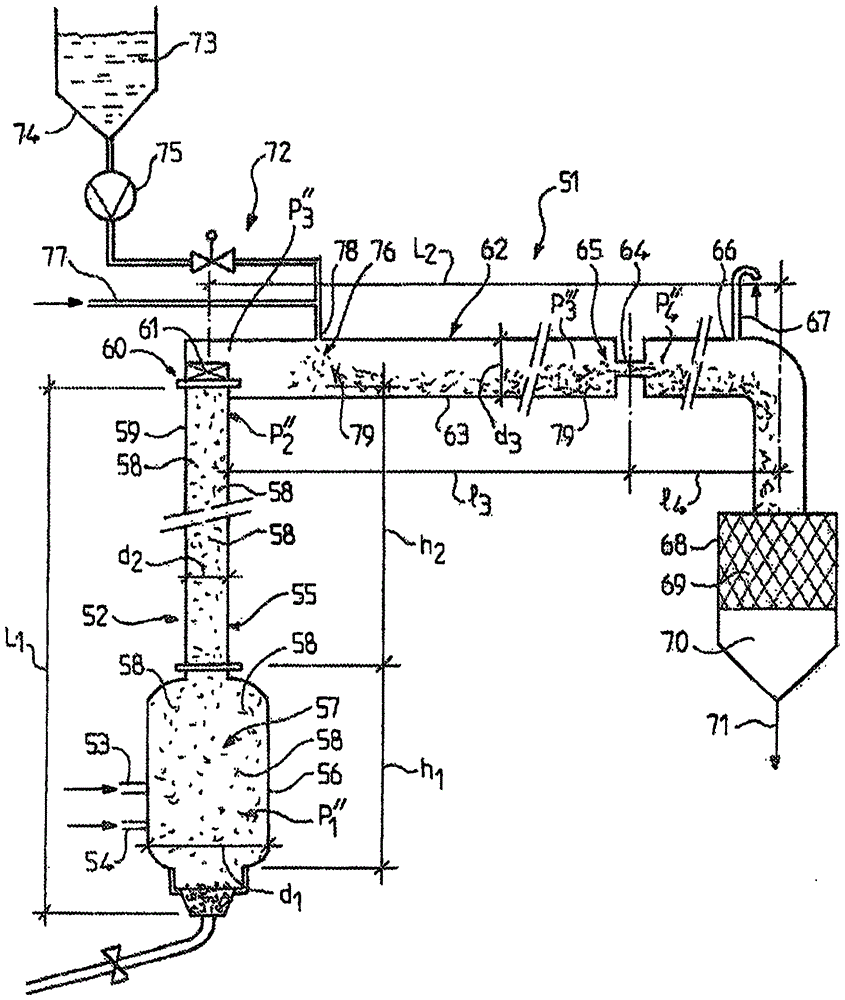

Method used

Image

Examples

Embodiment 4

[0139] Big bag; Example 4: 100 g / l after 24h, 115 g / l after 7 days and 221 g / l after 1 month.

[0140] Big bag; Example 5: 144 g / l after 24 h, 154 g / l after 7 days and 459 g / l after 1 month.

[0141] Big bag; Example 4: 120g / l after 24h (while raining all night) and 402g / l after 1 month.

[0142] It is to be noted that the sludge treated according to the invention is initially liquid.

[0143] Up to 30g / l, theoretically no dilution is required. However, if the sludge is thicker, for example above 40 g / l, it can be diluted at the inlet of the plant to enable a satisfactory pumping of the sludge, recalling that the The sludge is organic sludge, ie for which the MO (Matière Organique, organic matter) ratio relative to the MS (Matière en Suspension, suspended matter) ratio is 65% to 85%. The term "organic substance" is understood to mean essentially phospholipids, polysaccharides, proteins, alkali metals, alkaline earth and / or metals . . .

[0144] Another operating example is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com