Method for calibrating a robot and a robot system

A robot system and robot technology, applied in the field of calibration robots, can solve problems such as difficult optimization problems and limited final accuracy of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

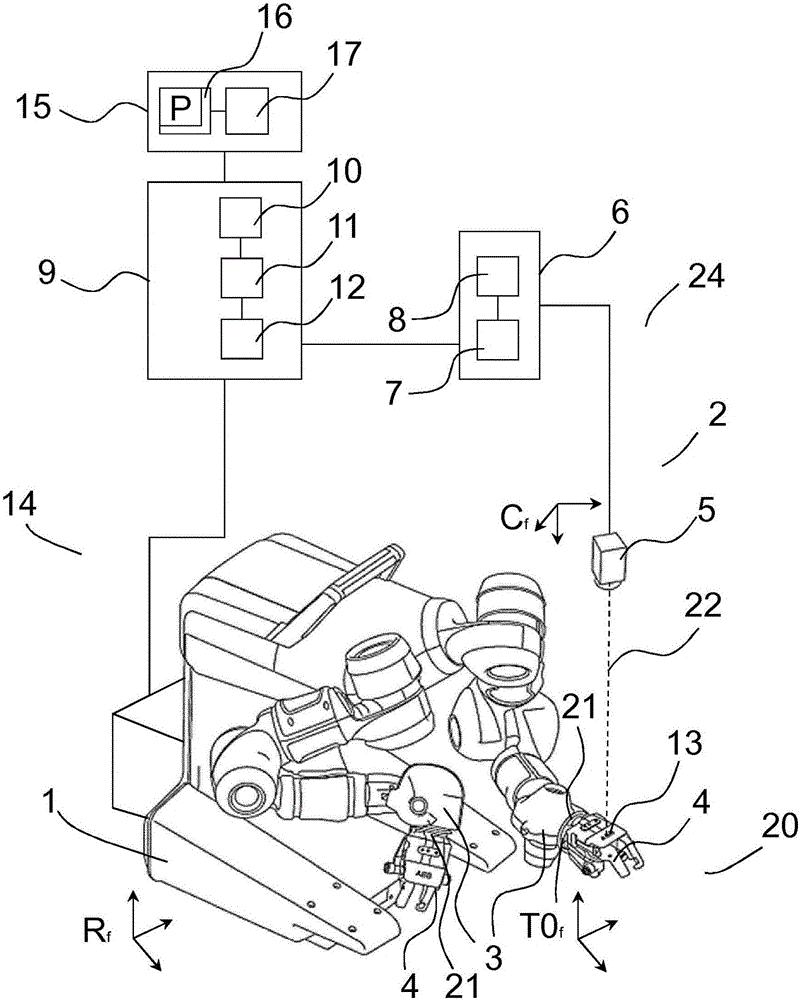

[0041] figure 1 An example of a robotic system 14 is illustrated. The robot system 14 includes defining the robot coordinate system R f The robot 1 and define the camera coordinate system C f Object Recognition Unit 2. Robot 1 is a redundant robot and has seven degrees of freedom. figure 1 The robot 1 shown in is a dual-arm robot with two robot arms 3, but the invention can be used with all types of robots. Specifically, the present invention is also applicable to articulated robots having six degrees of freedom.

[0042] figure 1 Each robot arm 3 in has a plurality of links connected in series. The movement of each of these linkages may be a translational movement or a rotation about an axis or a combination. These two changes in movement give each link a mechanical degree of freedom around or along what will hereinafter be referred to as a joint. The joints may be actuated by servo-controlled motors, controlled via feedback from the measured motion of the motors. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com