Insulated anti-corrosion silicon steel sheet for wind driven generator rotor

A technology for wind turbines and silicon steel sheets, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of poor insulation and corrosion resistance of silicon steel sheets, heavy solid silicon steel sheet rotors, and low energy conversion efficiency. and other problems, to achieve the effects of improving insulation and corrosion resistance, high energy conversion efficiency, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

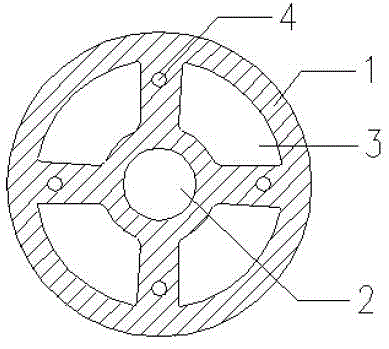

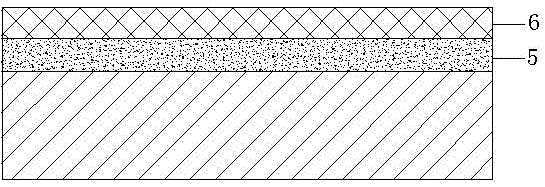

[0012] see figure 1 and figure 2 , the present invention relates to an insulating and anti-corrosion silicon steel sheet for the rotor of a wind power generator, which includes a silicon steel sheet body 1, the silicon steel sheet body 1 is in a circular structure, the central hole is the mounting shaft hole, and the outer side is a slot for the coil. The chip body 1 is provided with a heat dissipation hole 2, the heat dissipation hole 2 is a trapezoidal structure, the heat dissipation hole 2 is double or multi-layer, and the width of the heat dissipation hole 2 is smaller than the distance between two adjacent heat dissipation holes 2 Half, the surface of the silicon steel sheet body 1 is coated with an insulating layer 5 and an anti-corrosion layer 6 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com