Electromagnetically actuable proportional flow valve, and method for operating an electromagnetically actuable proportional flow valve

A flow proportional valve, electromagnetic operation technology, applied in the direction of flow control, non-electric variable control, valve heating/cooling device, etc., can solve the problem of filter element clogging, to ensure flow regulation, reduce the risk of clogging, reliable flow Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

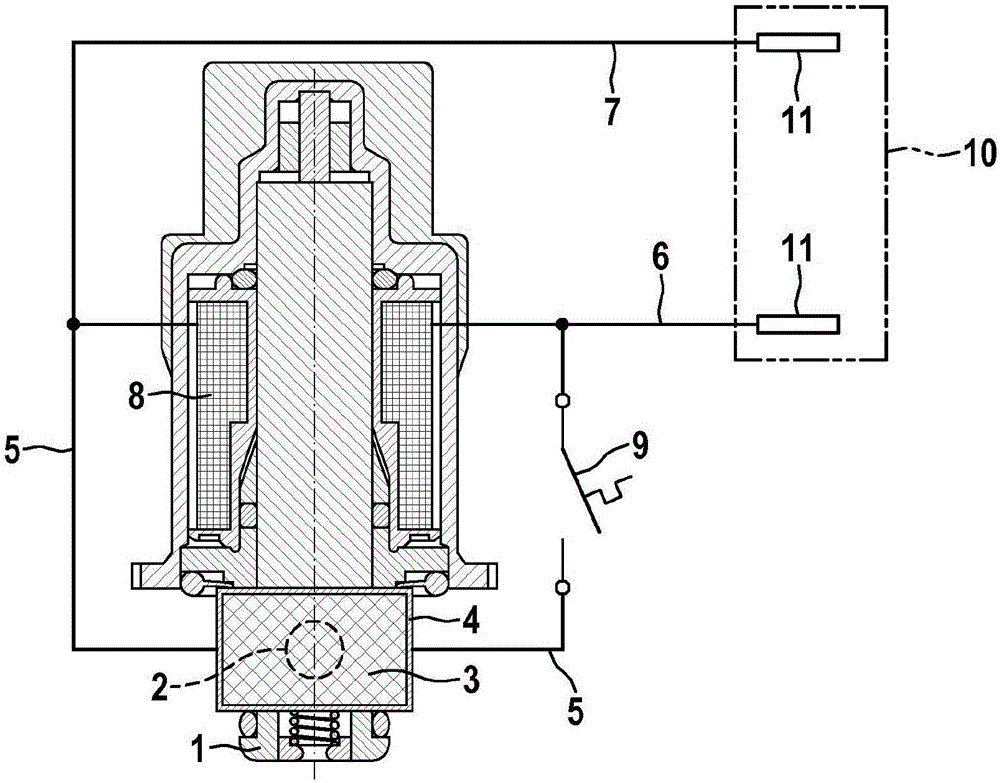

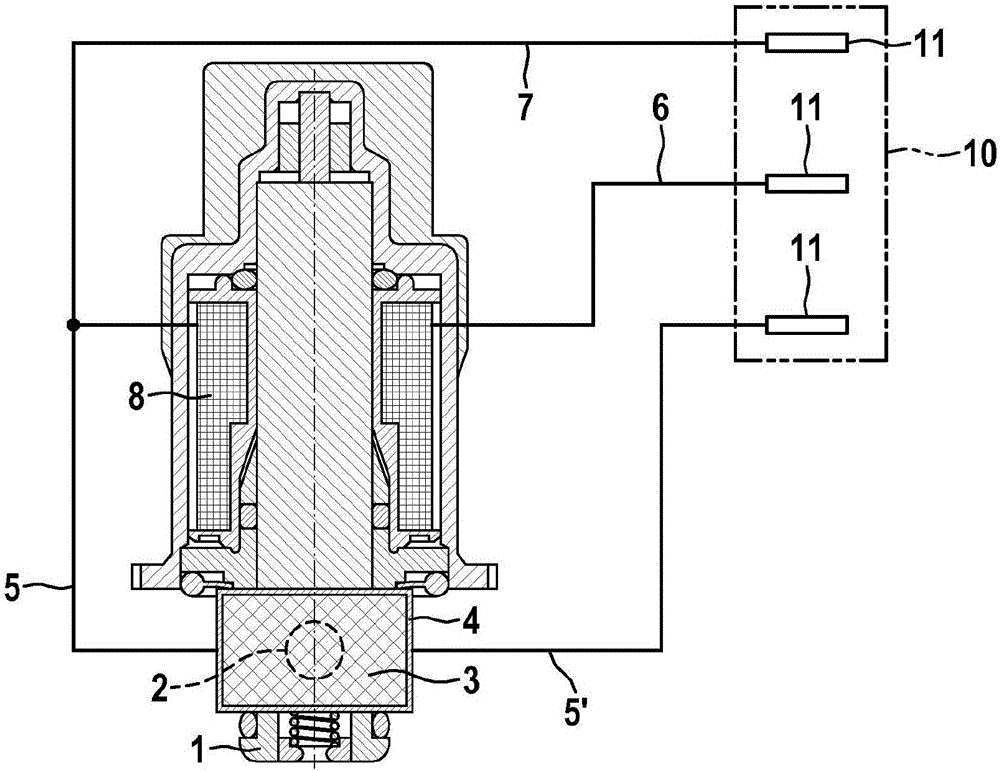

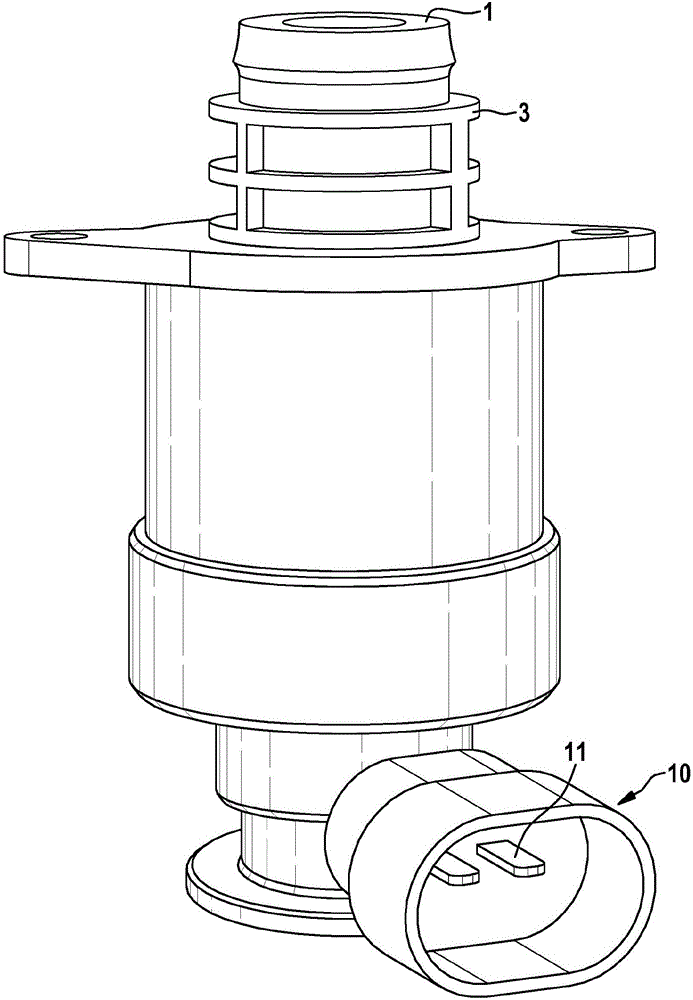

[0024] figure 1 The flow proportional valve shown in includes a valve housing 1 in which at least one inlet opening 2 is formed. The inlet opening 2 is in the present case embodied as a radial bore and is surrounded on the outer peripheral side by a filter element or sieve 3 . At least one heating wire 4 is integrated into the sieve or mesh of the filter element or sieve 3 , said heating wire being part of an electrical heating device for heating the filter element or sieve 3 . The heating wires 4 are respectively connected via electrical lines 5 to electrical lines 6 and 7 of an electromagnet 8 capable of actuating the valve. The actuation of the filter element or the electric heating of the sieve 3 thus takes place parallel to the actuation of the electromagnet 8 . In order to enable a desired actuation of the electrical heating device, a temperature switch 9 is arranged in the electrical line 5 . The temperature switch is only switched on when the temperature of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com