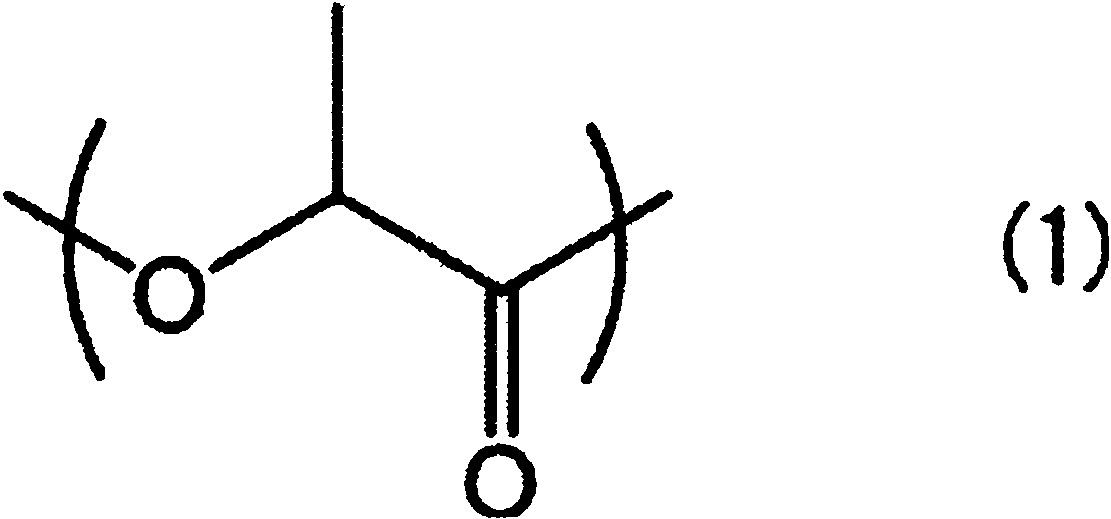

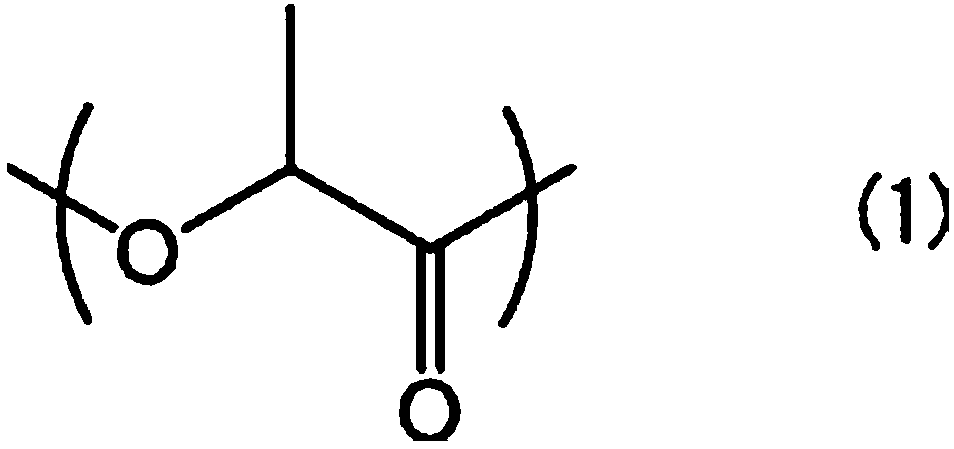

Polymer piezoelectric material, laminate, method for producing piezoelectric polymer material, and method for producing laminate

A piezoelectric material and polymer technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve Inhomogeneous electrical properties of laminated structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0163] -Sample preparation-

[0164] The helical chiral polymer (A) was dissolved in a solvent (for example, chloroform) at 40° C. to prepare a sample solution with a concentration of 1 mg / mL.

[0165] -Measurement conditions-

[0166] At a temperature of 40° C., 0.1 mL of the sample solution was introduced into the column using a solvent [chloroform] at a flow rate of 1 mL / min.

[0167] The concentration of the sample in the sample solution separated by the column was measured using a differential refractometer. A universal calibration curve was prepared using polystyrene standard samples, and the weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn) of the helical chiral polymer (A) were calculated.

[0168] As the polylactic acid-based polymer as an example of the helical chiral polymer (A), commercially available polylactic acid can be used.

[0169] Examples of commercially available products include PURASORB (PD, PL) manufactured by PURAC, LAC...

Embodiment 1

[0212] [Production of piezoelectric polymer materials and laminates]

[0213]

[0214] Polylactic acid (PLA) (trade name: Ingeo TM biopolymer, brand name: 4032D, weight-average molecular weight Mw: 200,000) into the feed hopper of the extrusion molding machine, while heating at 220°C to 230°C, extrude from a T-die with a width of 2000mm to make it with 50 A cast roll (cast roll) at °C was contacted for 0.5 minutes to form a pre-crystallized film with a thickness of 150 μm (molding step). The crystallinity of the obtained precrystallized film was measured and found to be 4.91%.

[0215] For the obtained precrystallized film, while heating at 70° C., stretching was started in a roll-to-roll manner at a stretching speed of 1650 mm / min, and uniaxially stretched in the MD direction to 3.5 times to obtain a uniaxially stretched film (stretching step).

[0216] Then, the uniaxially stretched film was annealed by contacting the roll heated to 130° C. for 78 seconds in a roll-to-r...

Embodiment 2

[0295] In Example 2, the piezoelectric polymer material and the laminate were produced under the same conditions as in Example 1 except that the scanning speed as the laser irradiation condition was changed to 30 m / min (500 mm / sec).

[0296] Table 1 shows the measurement results in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com