Foot-pedaling paddy rice threshing machine

A thresher and paddy technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of many stones, cost a lot of labor, and the harvester cannot adapt to mountain terrain, etc., and achieve the effect of easy detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

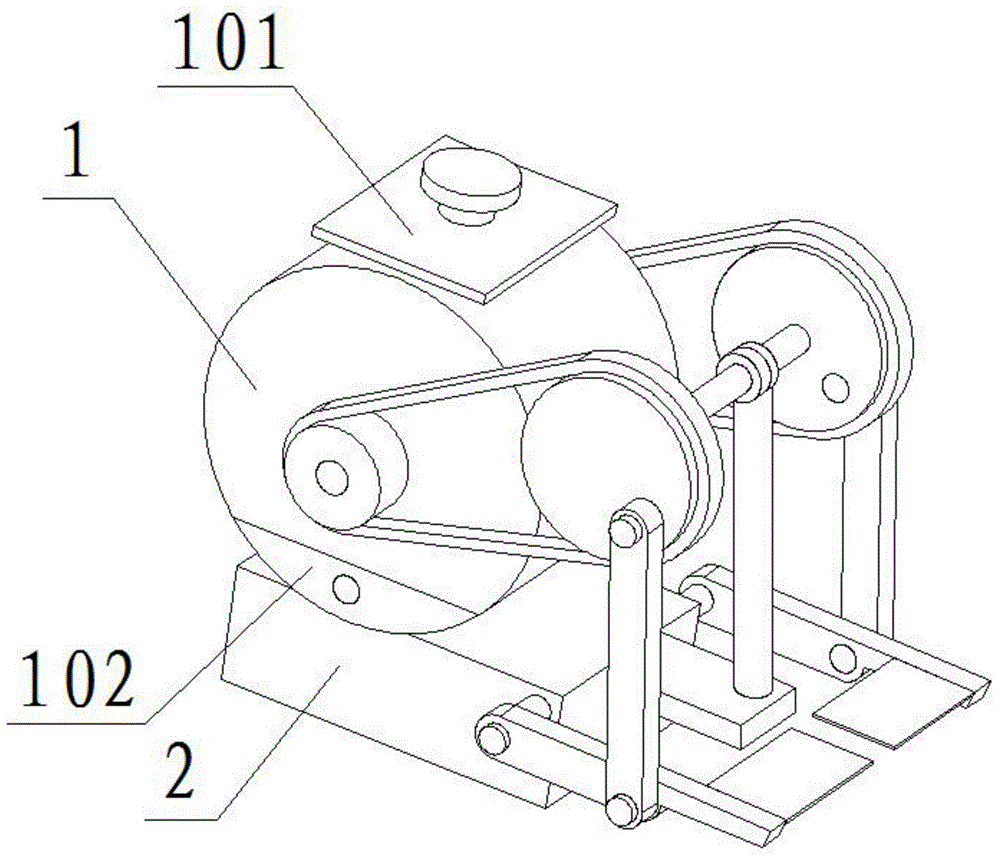

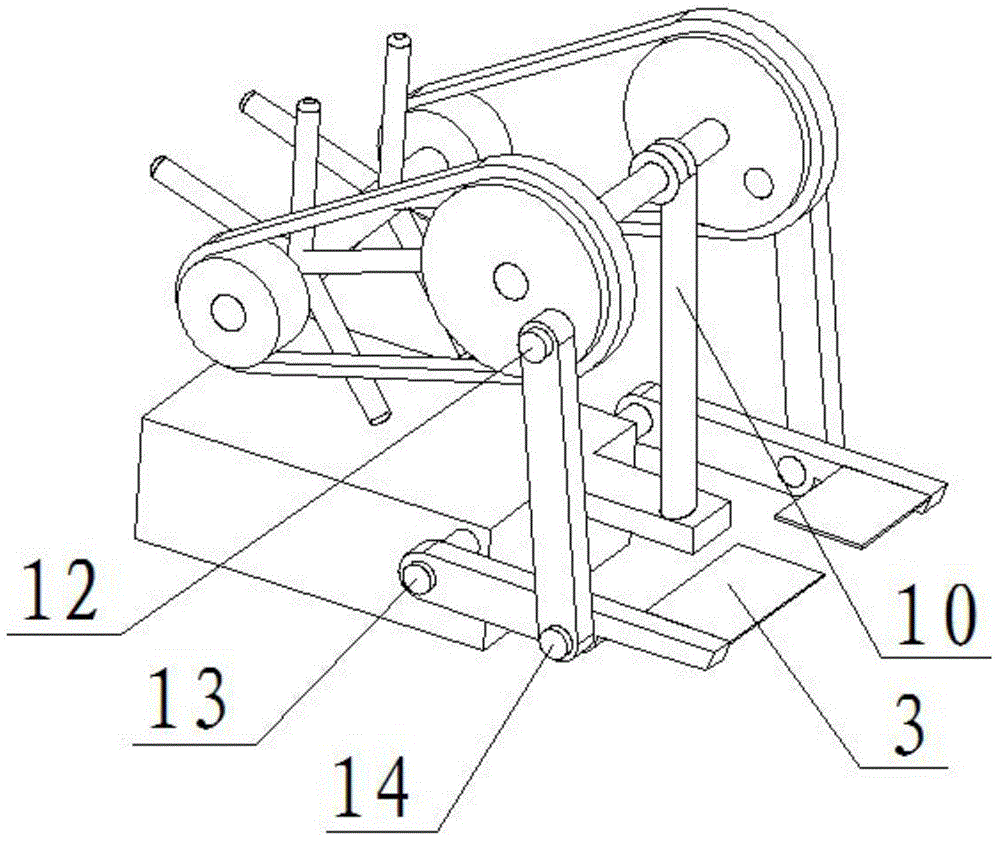

[0017] A foot-operated rice thresher, comprising a frame 2, a material holding drum 1 and two sets of stirring mechanisms,

[0018] The parts, shapes and structures of the two sets of stirring mechanisms are exactly the same. The two sets of stirring mechanisms operate independently and are symmetrically installed on the frame and the drum.

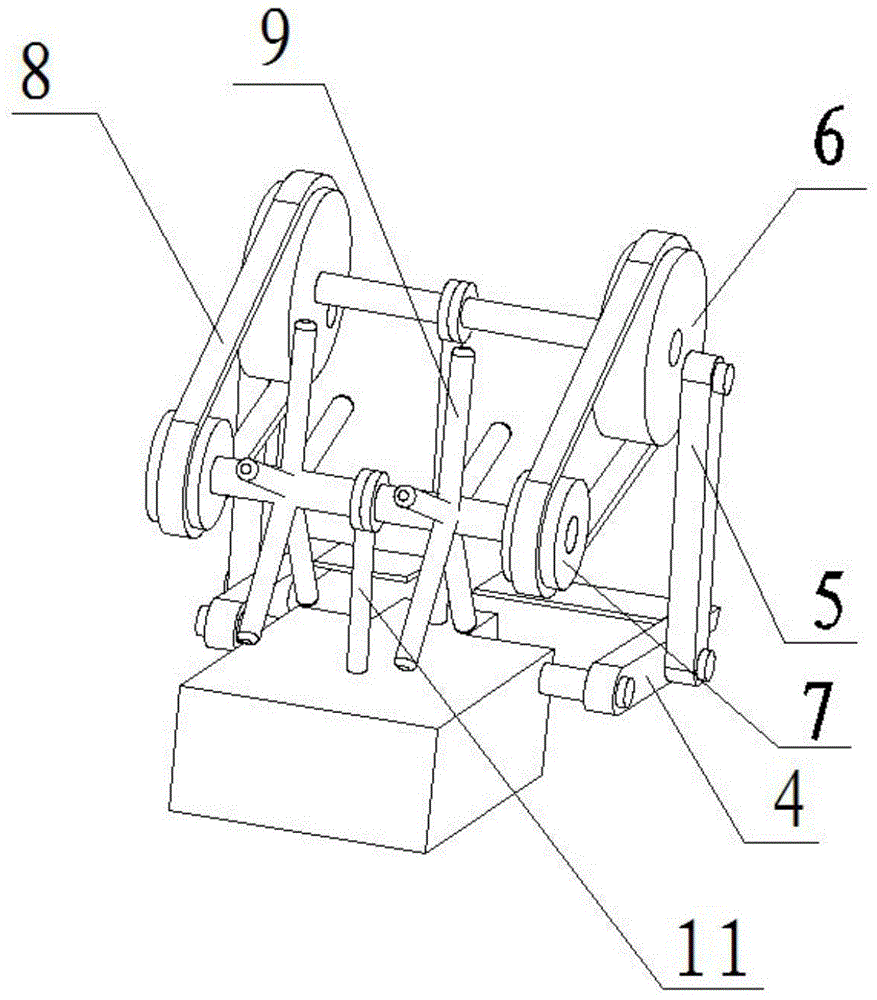

[0019] Each set of mixing mechanism includes pedal 3, first connecting rod 4, second connecting rod 5, driving pulley 6, driven pulley 7, belt 8, stirring paddle wheel 9, first support rod 10 and second support Rod 11, the specific connection method is as follows:

[0020] The front end of the first connecting rod 4 is connected to the frame 2 through the first rotating pair 13, the rear end of the first connecting rod 4 has a pedal 3, and one end of the second connecting rod 5 is connected to the first connecting rod 4 through the second rotating pair 14. Above, the other end of the second connecting rod 5 is connected to the driving pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com