Intelligent carbon brush head rotating arcing machine

A carbon brush and intelligent technology, which is applied in the direction of grinding workpiece supports, grinding machines, metal processing equipment, etc., can solve the problems of increasing equipment procurement costs, unstable product quality, and increasing production costs, so as to improve equipment utilization and reduce labor costs. and time, and the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

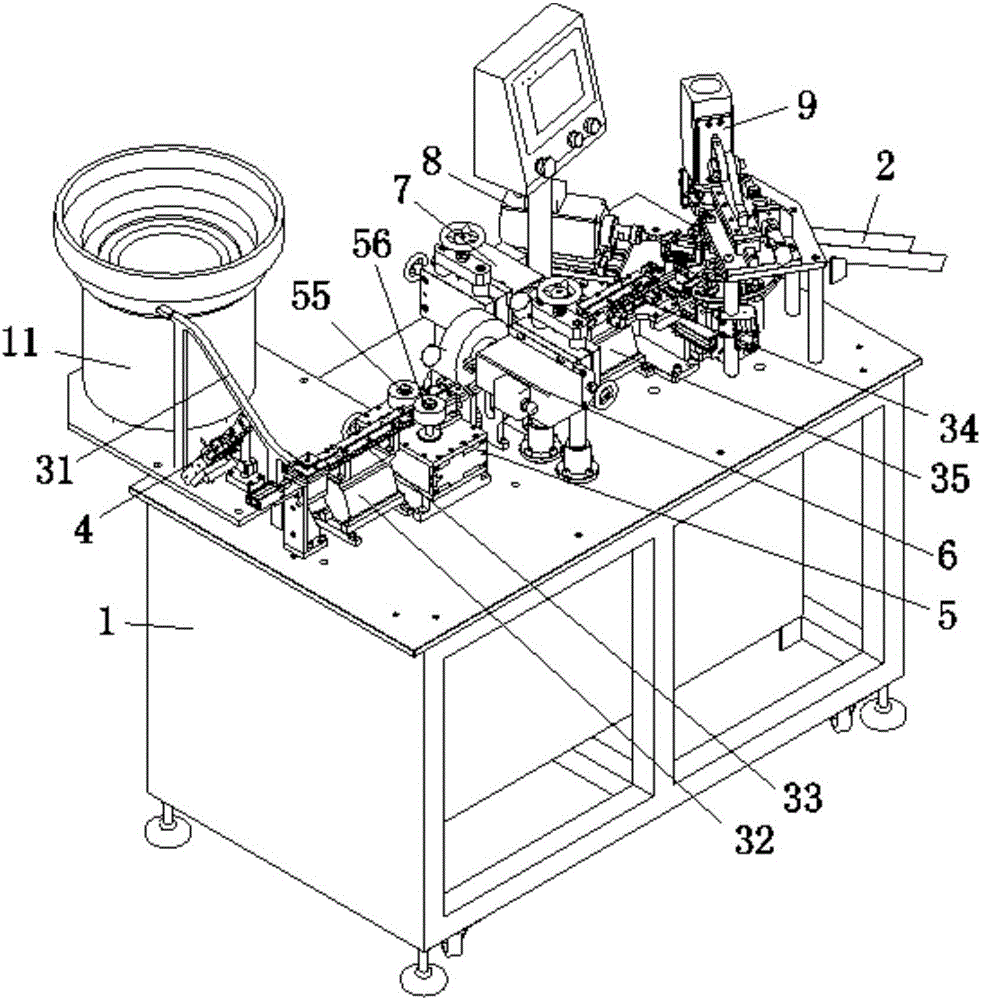

[0040] Such as figure 1As shown, it is a schematic structural diagram of the intelligent carbon brush swivel head arcing machine provided by the present invention. It can be seen from the figure that it includes: a fixture for clamping the carbon brush installed at the introduction station; The swivel device 8; the arc device 9 installed at the arc station; the export device 2 installed at the export station; wherein, when the clamp holding the carbon brush is rotated to the swivel station, by The swivel device performs swivel processing on the front face of the carbon brush; after the swivel processing, the fixture with the carbon brush is rotated to the arcing station, and the rear end face of the carbon brush is arced by the arcing device; After the arc treatment, the fixture with the carbon brushes is rotated to the derivation station, and the carbon brushes are discharged from the fixtures for clamping them through the derivation device 2 .

[0041] Further, the smart ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com