Grinding wheel clamp capable of being used on lathe

A grinding wheel and fixture technology, applied in manufacturing tools, ultra-finishing machines, metal processing equipment, etc., can solve the problems of waiting in line, reduce the efficiency of training, increase the risk factor, etc., achieve easy installation and disassembly, avoid crowd gathering, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

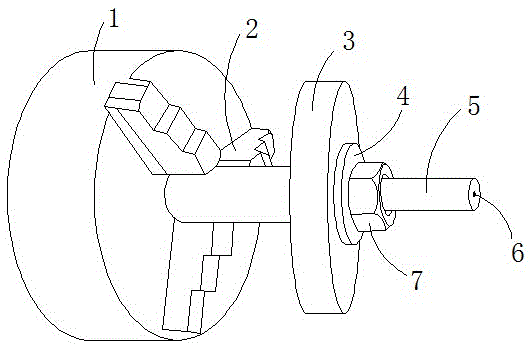

[0012] Such as figure 1 As shown, a grinding wheel clamp that can be used in a lathe includes a chuck 1, jaws 2 and a grinding wheel 3. The clamp also includes a stepped shaft 5, a grinding wheel stopper 4 and a fastening nut 7. The small size of the stepped shaft 5 There is an external thread on the outer circle of the end, and a central hole 6 is opened at the center of the head of the small end of the step shaft 5. One side of the grinding wheel 3 is installed close to the shoulder of the step shaft 5, and the grinding wheel stopper 4 is close to the side of the grinding wheel 3. On the other hand, the fastening nut 7 is screwed on one side of the grinding wheel stopper 4 by external threads.

[0013] Such as figure 1 As shown, a grinding wheel clamp that can be used for lathes, the stepped shaft 5 is a three-stage stepped shaft, the total length of the stepped shaft 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com