Composite coating and marker

A composite coating and marking technology, applied in the field of electric power, can solve the problems of easily pasted small advertisements and high breakage rate of signs, and achieve the effect of solving the problems of pasting and clearing, improving tear resistance and good anti-breakage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned coating can be sprayed. Specifically, each layer is sprayed on the base material in sequence, and after being cured, it can be formed.

[0032] In addition, the present invention also provides a sign, which comprises the above-mentioned composite coating. In the actual application process, the above-mentioned composite coating can be directly used as a mark.

[0033] The above-mentioned marking provided by the present invention includes the above-mentioned composite coating. The raw materials of the sealing layer include 36-77 parts of water, 0.9-2.2 parts of the first pH regulator, and 22-61 parts of toughening agent. This layer is in direct contact with the base material on which the logo is attached, and has high tear resistance. Therefore, the tear resistance of the coating can be significantly improved. Using this coating as an anti-collision logo has good anti-damage performance. The above-mentioned coating also incl...

Embodiment 1 to 6

[0042] Composite coating manufacturing process:

[0043] Configure the raw paint for the sealing layer, rough layer and finish layer, use the pole as the base material, and spray the sealing primer coating on the base material by spraying. After curing, further spray the rough layer paint. After the rough layer is cured, further spray the varnish coating, and solidify to form a composite coating.

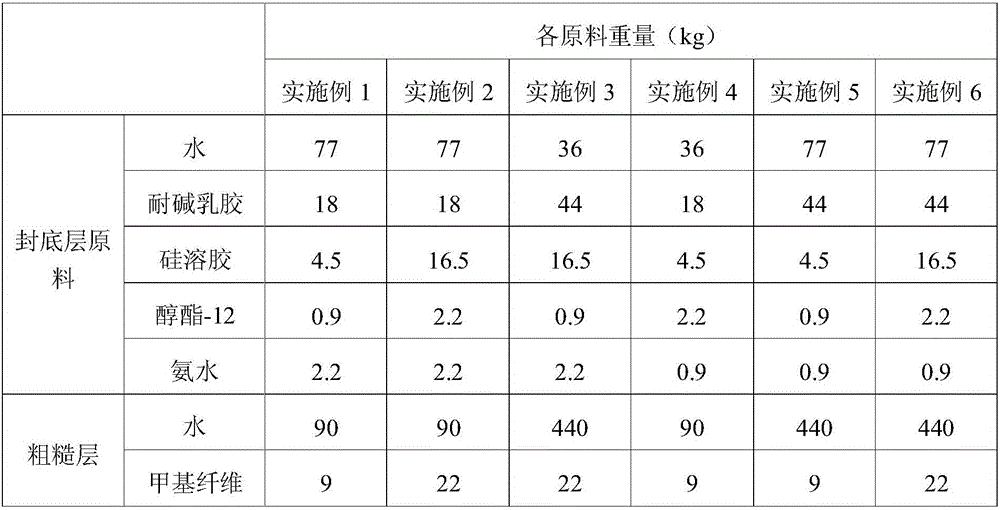

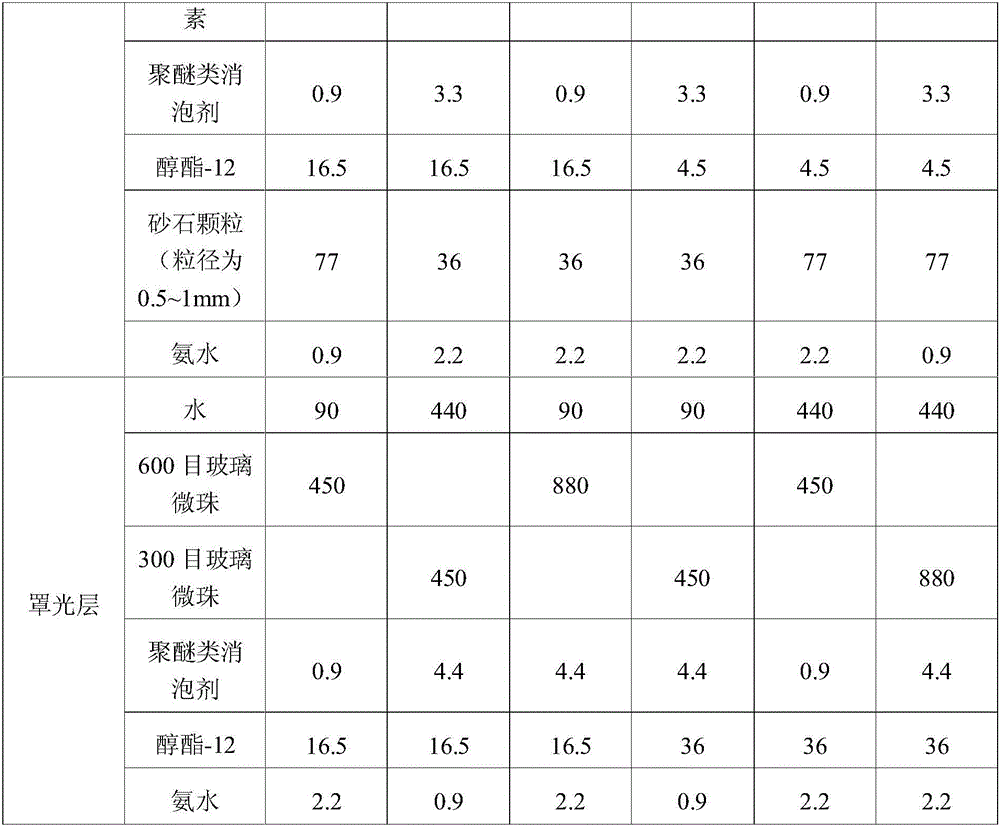

[0044] The coating material of each embodiment is as shown in Table 1:

[0045] Table I

[0046]

[0047]

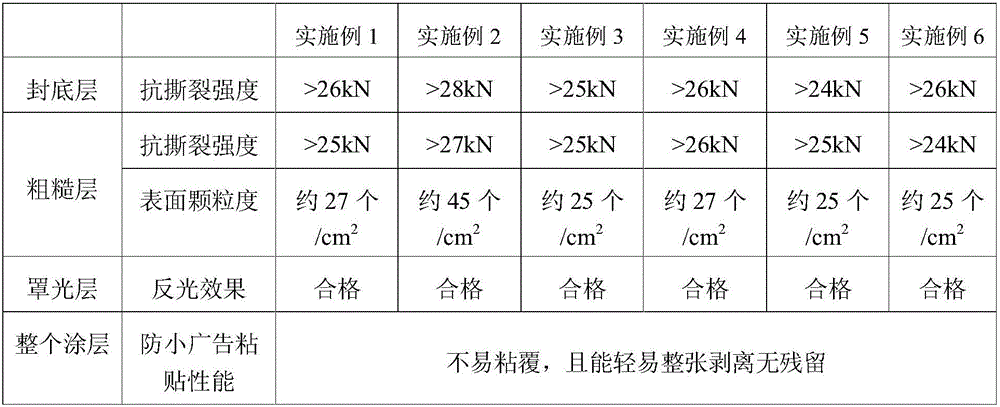

[0048] The performance characterization results of each layer of the composite coating in Examples 1 to 6 are shown in Table 2:

[0049] Table II

[0050]

[0051] From the above description, it can be seen that the above-mentioned embodiments of the present invention achieve the following technical effects: each layer of the composite coating prepared in the above-mentioned embodiments has high tear resistance. At the same time, it can prevent small advertisements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com