High-viscosity glue solution jet-dispensing quality improving method and dispensing device

A technology of dispensing device and spray point, which is used in devices for coating liquid on the surface, liquid chemical plating, coating, etc. , The effect of solving injection difficulties and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

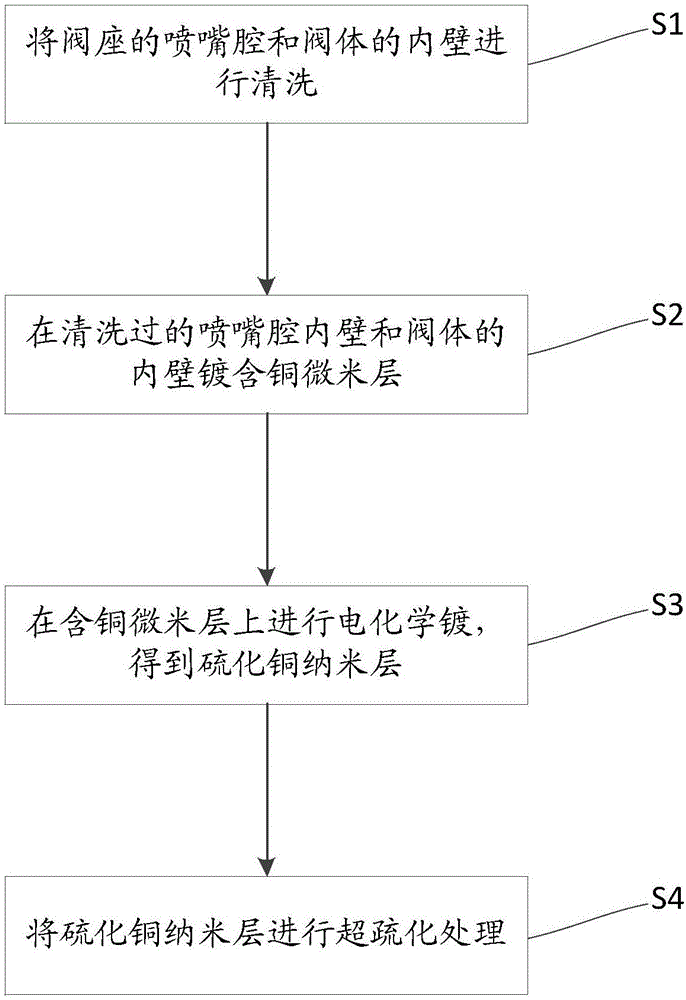

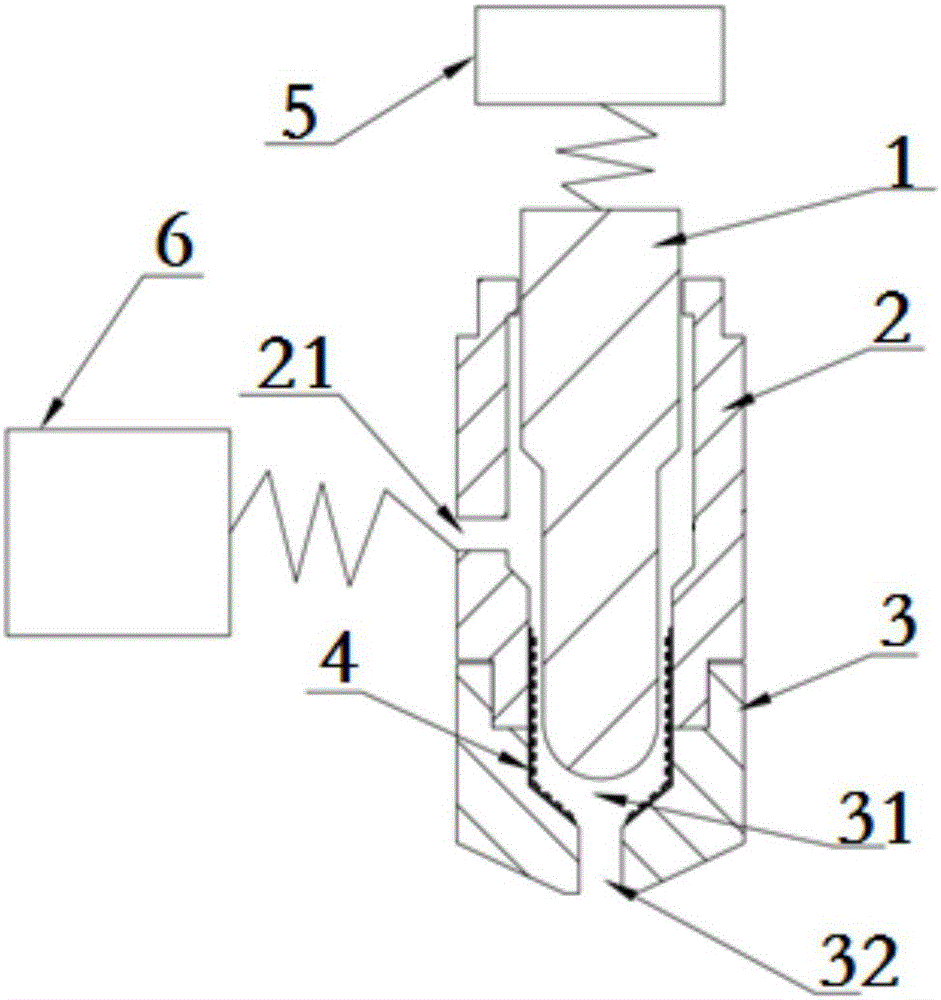

[0041] The core of the present invention is to provide a high-viscosity glue jet dispensing quality improvement method and a glue dispensing device, through the copper sulfide nanostructure on the surface of the inner wall, the super-phobic properties of the high-viscosity glue are effectively increased to drive the high-viscosity glue The flowing external force makes the direction of the force acting on the high-viscosity glue point to the injection port more consistently, and the high-viscosity glue is more likely to be ejected at a high speed and in a stable state, which solves the difficult problem of high-viscosity glue injection at the current stage. At the same time improve the efficiency of jet dispensing.

[0042] In order for those skilled in the art to better understand the technical solution of the present invention, the method for improving the quality of high-viscosity glue jet dispensing and the dispensing device of the present application will be described in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com