Mini distributed fiber temperature measuring calibration device and method

A distributed optical fiber and calibration device technology, applied in the direction of measuring devices, thermometers, measuring heat, etc., can solve problems such as calibration and transportation that take a long time, affect the promotion of instrument use, and affect test results, etc., to improve the calibration range , reduce the difficulty and requirements of calibration, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

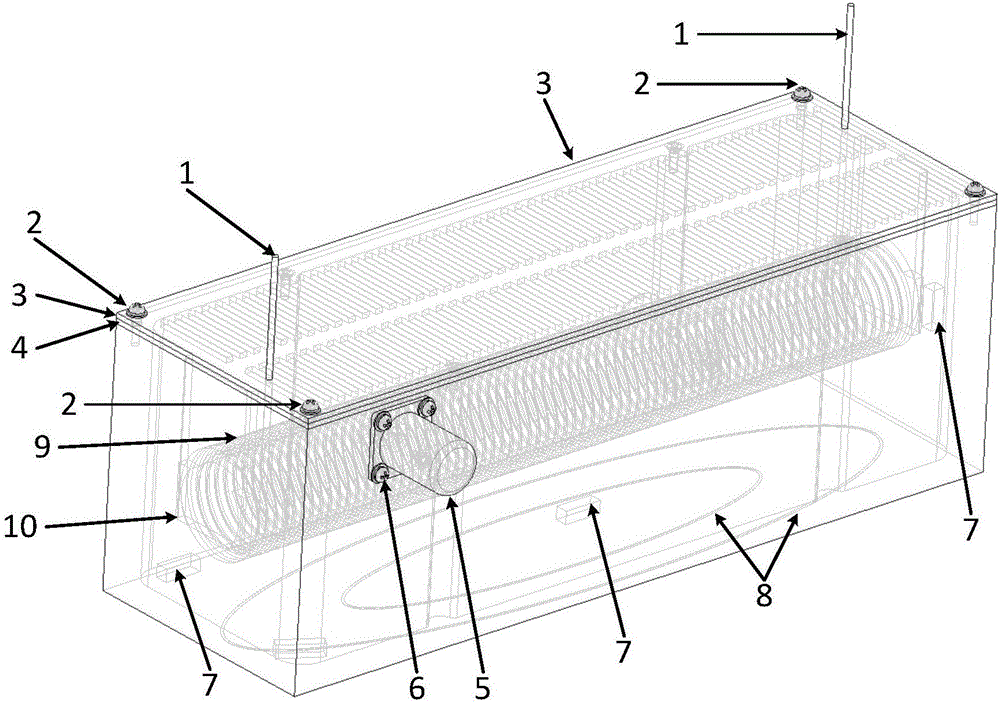

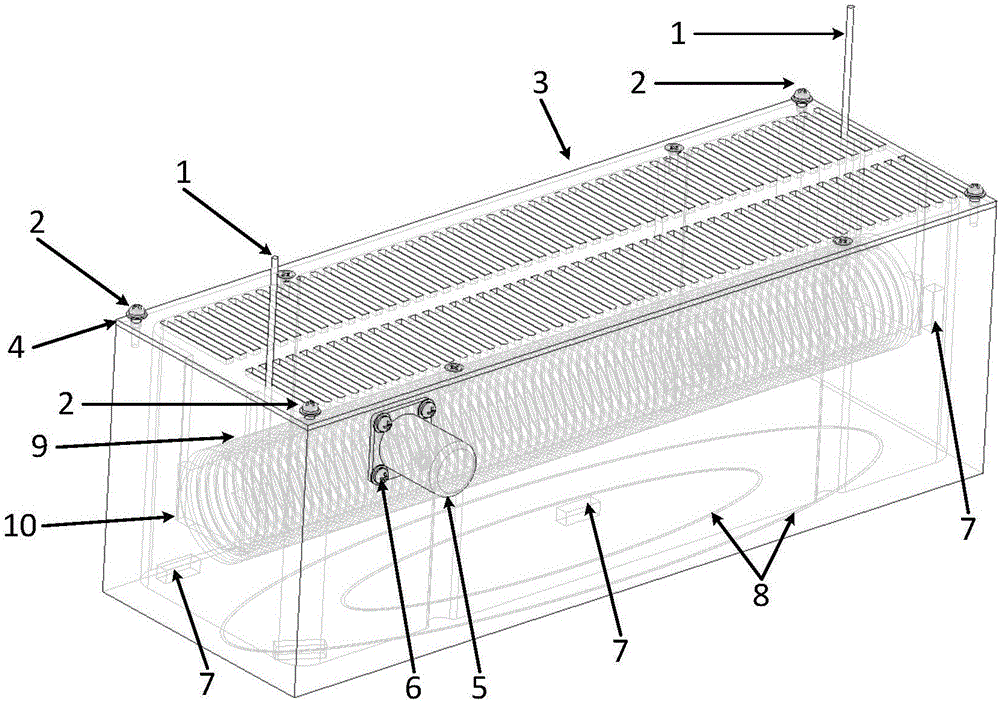

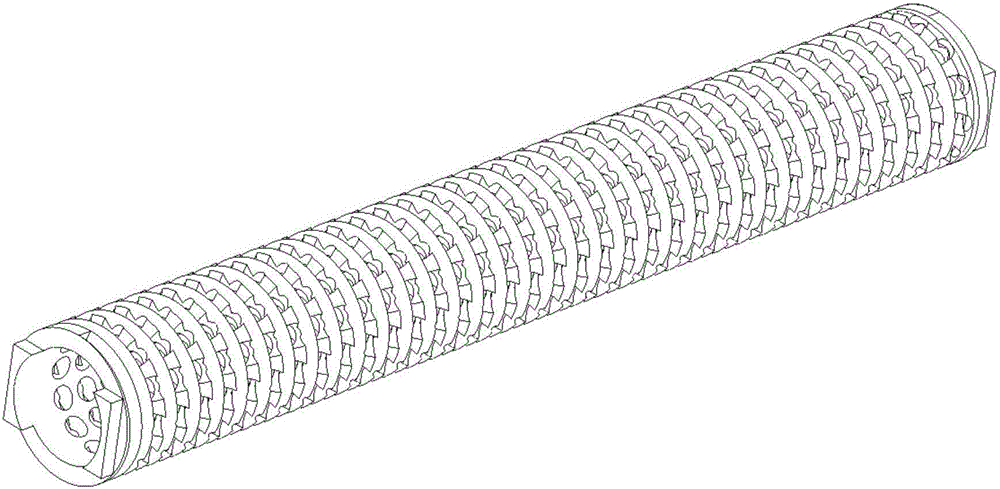

[0039] like figure 1 As shown, a miniaturized distributed optical fiber temperature measurement and calibration device includes a box, the upper panel of the box can be opened and closed, and the upper panel is provided with a through hole for the measured optical fiber 1 to pass through; The box body is provided with a detachable optical fiber winding column 9, the bottom of the box body is provided with a heating resistance wire 8, and the box body is also provided with a heat transfer fluid working medium and a temperature sensor 7, and the temperature sensor 7 and The heating resistance wires 8 are all connected with the calibration device controller.

[0040] Two micromotors 5 are also fixed on the side wall of the box, and the micromotors 5 are connected to the propellers arranged inside the box, and the micromotors 5 are also connected to the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com