Internal Stress Harvesting Device of Multilayer Annular Array Abrasive Group

An internal stress, annular array technology, applied in the direction of measuring devices, measuring force, force/torque/work measuring instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

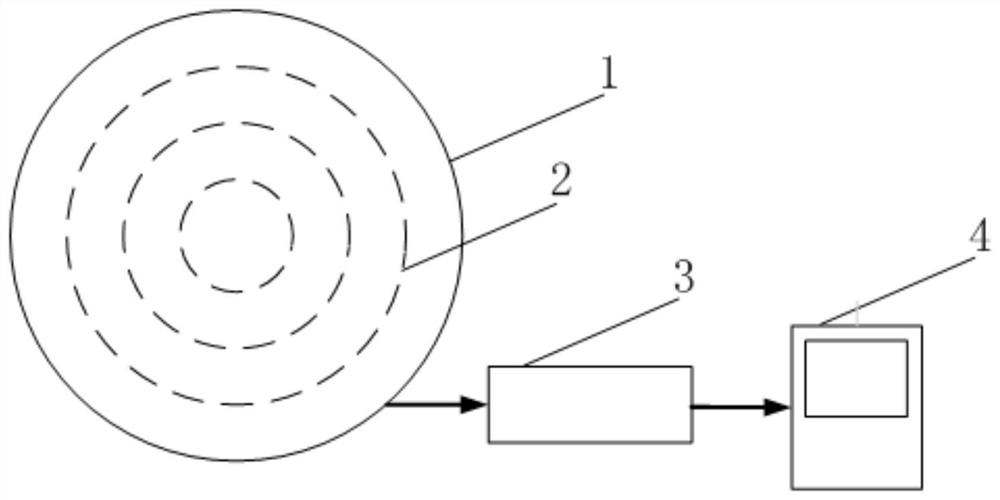

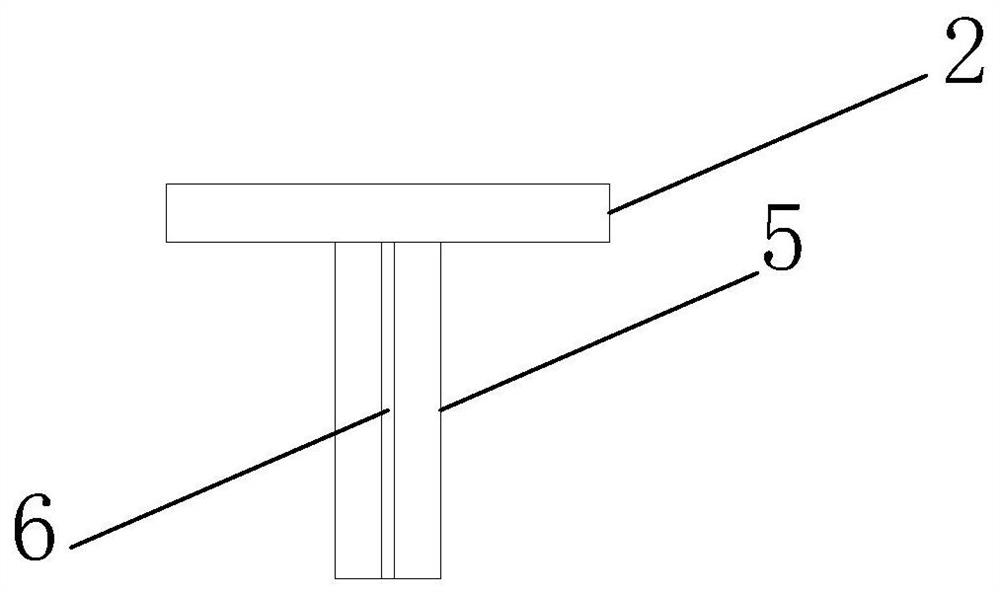

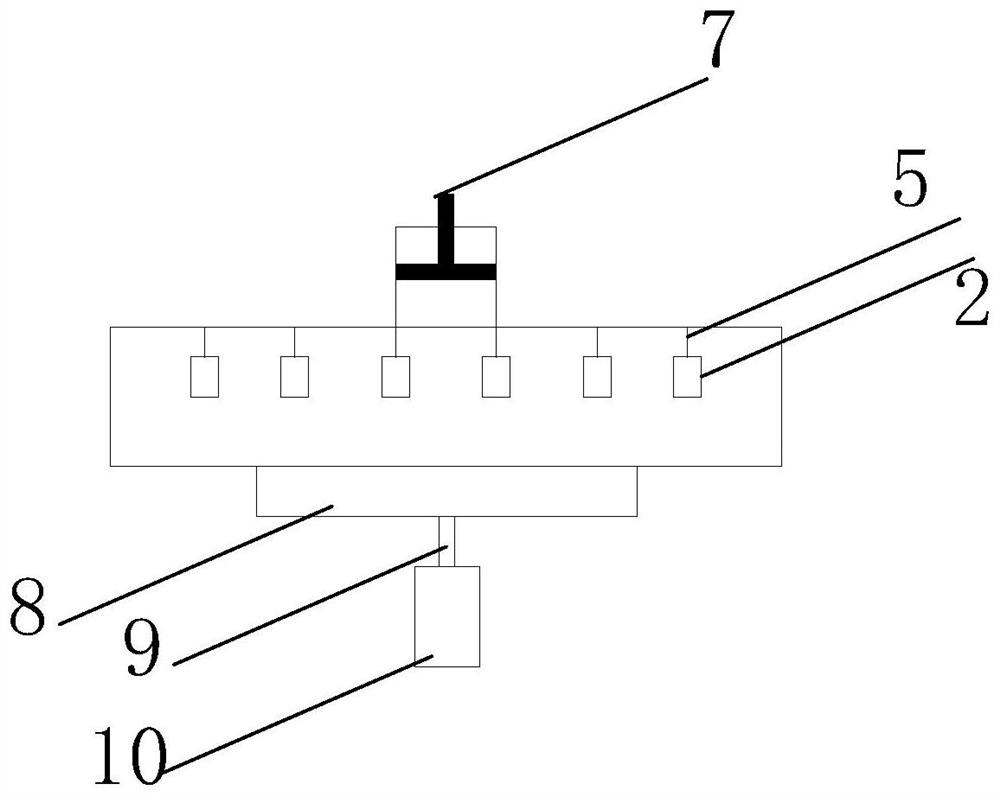

[0026] The internal stress collection device of the multi-layer annular array abrasive particle group according to the present invention includes a cavity 1 for accommodating and constraining the abrasive particle group, a multi-layer annular strain gauge array 2 for collecting dynamic changes in the stress of the abrasive particle group, a lower machine 3, a display 4 for displaying abrasive grain groups, a driving device 10 with a speed regulating knob and a piston device 7, the cavity 1 is a closed hollow cavity, and a feeding port with a seal is provided on the cavity, And it is fixed with a piston device 7 that can provide a controllable pressure of the cavity. The orbiting central axis of the cavity 1 is connected with the power output shaft 9 of the drive device 10 through the turntable 8, so that the cavity 1 can go around the cavity. The body is vertically arranged to rotate around the central axis 9; the inner surface of the bottom of the cavity 1 is used as a working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com