Waterproof roll tensile testing device

A testing device and waterproof membrane technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large impact and low precision, and achieve high sensitivity, stable movement, and accurate and reliable experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

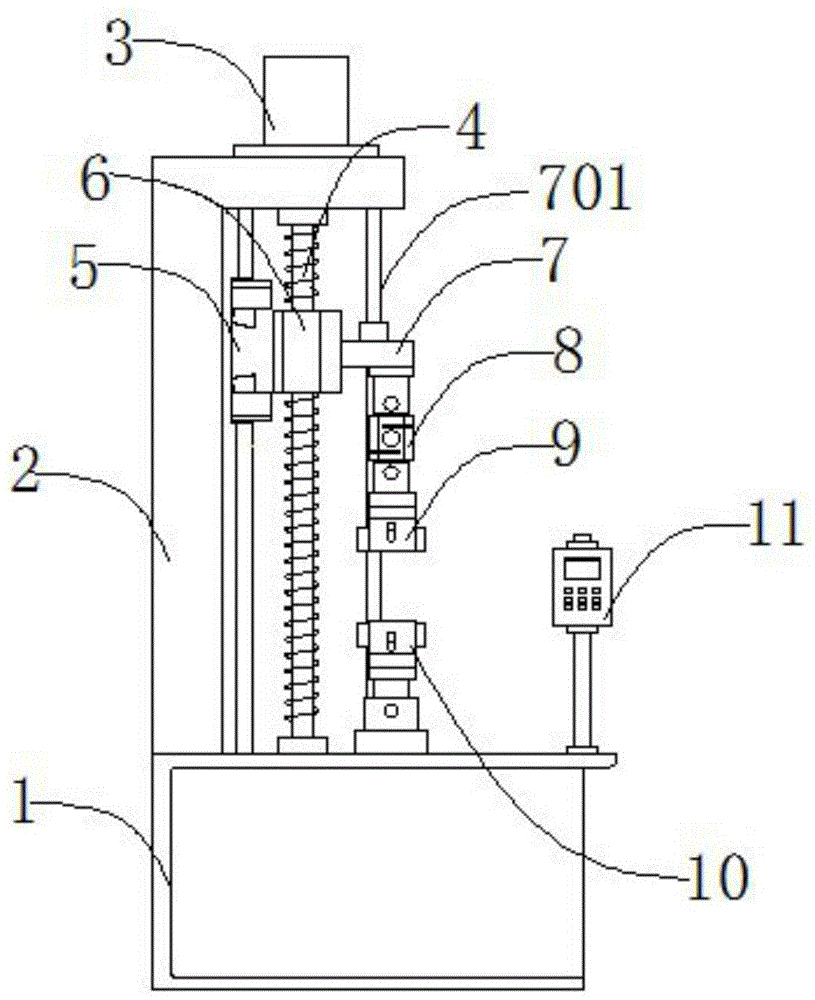

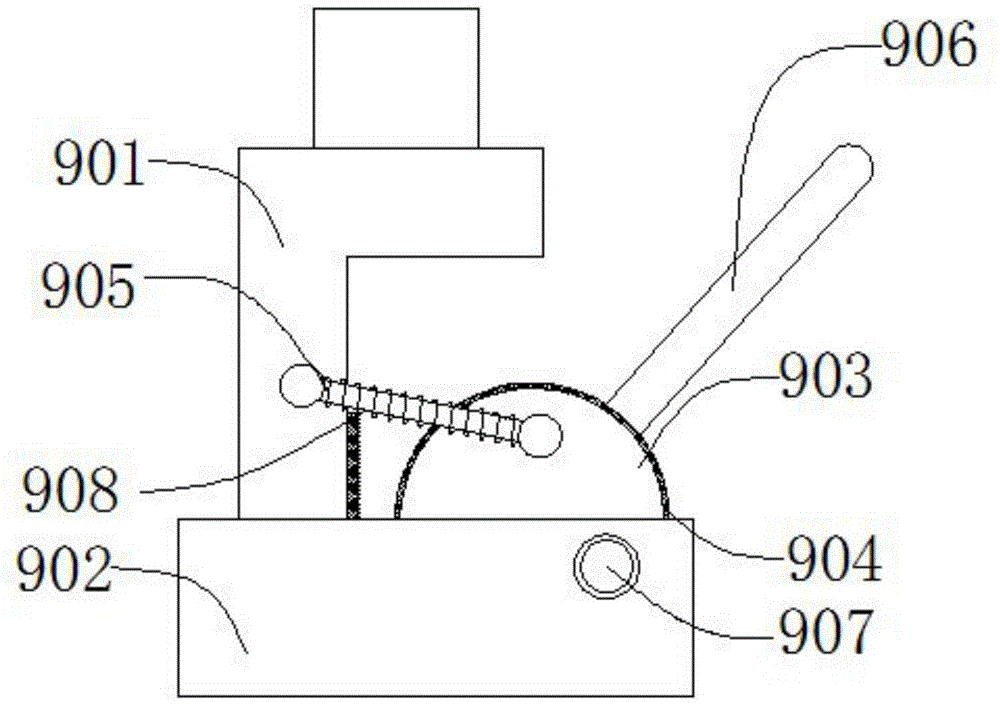

[0026] Such as figure 1 , figure 2 As shown, a waterproof membrane tensile test device includes a frame 1, a column 2, a servo motor 3, a screw 4, a linear guide 5, a feed nut 6, a base 7, a tension sensor 8, and an upper chuck 9 , the lower chuck 10, the controller 11, the column 2 is located at the left upper end of the frame 1, the column 2 is threadedly connected with the frame 1, the servo motor 3 is located at the upper end of the column 2, and the servo The motor 3 is threadedly connected with the column 2, the lead screw 4 is located at the lower end of the servo motor 3 and the upper end of the frame 1, the lead screw 4 is closely matched with the servo motor 3 and connected with the frame 1 in rotation, and the The linear guide rail 5 is located on the right side of the column 2, the linear guide rail 5 is threadedly connected with the column 2, the feed nut 6 is located on the outer wall of the lead screw 4 and is located on the right side of the linear guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com