Strip steel hole online detection method

A strip and hole technology, applied in the field of steel rolling, can solve problems such as product scrap, user hazards, product quality damage, etc., to avoid leaving the factory, reduce hazards, and improve strip quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

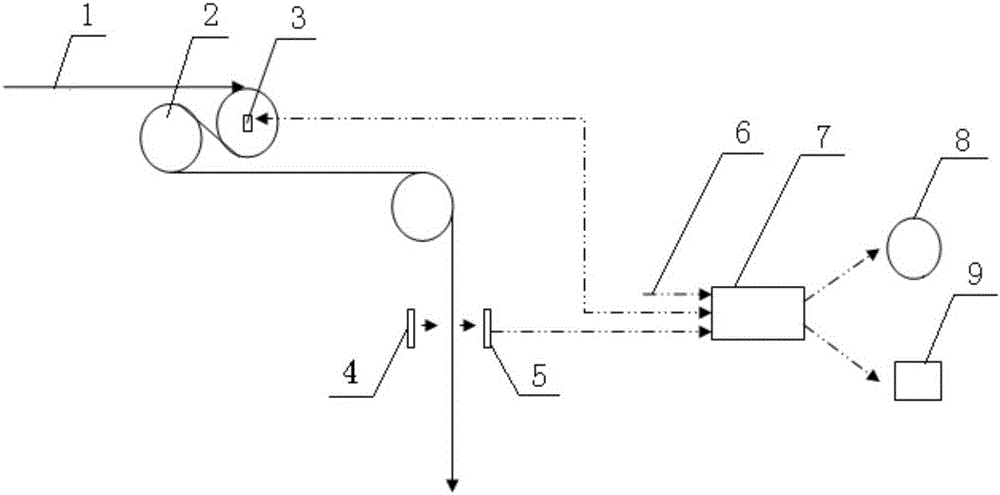

[0013] Depend on figure 1 It can be seen that the strip steel hole online detection device of the present invention is mainly composed of a code disc 3, a laser emitting assembly 4, a laser receiving assembly 5, a counter 6, a single-chip controller group 7, an acousto-optic alarm 8 and a display 9. The single-chip controller group 7 has a single-chip and a main single-chip. The laser emitting assembly 4 and the laser receiving assembly 5 are correspondingly arranged on both sides of the vertical strip steel 1 at the looper exit, the display 9 and the sound and light alarm 8 are arranged in the operating room, and the code disc 3 is installed on the coiler 2 synchronously with the strip steel. On the roller shaft, the code disc 3 is connected to the single-chip controller group 7 through the counter 6, and at the same time, the single-chip controller group 7 is also connected to the laser receiving component 5, the sound and light alarm 8 and the display 9 respectively.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com