Control method of electric tool and electric tool performing same

A technology of electric tools and control methods, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., and can solve the problems of troublesome manufacturing, complex structure of mechanical clutch, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

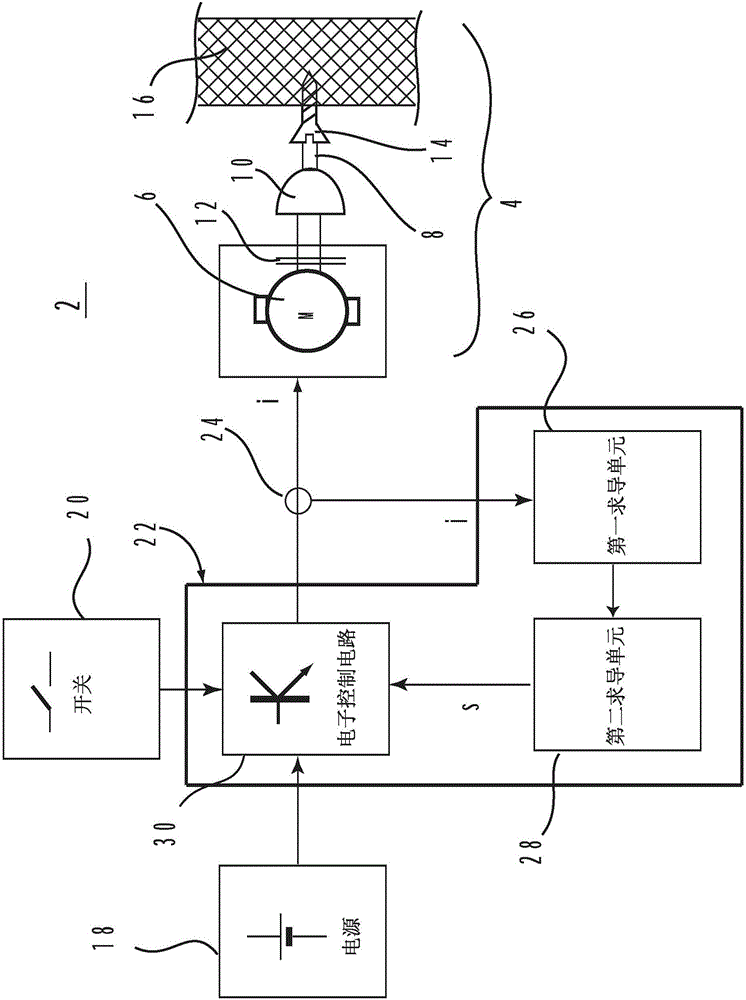

[0060] An embodiment of the present invention provides a control method of an electric tool, such as Figure 20 As shown, the method includes the following steps:

[0061] S1, measuring the parameters used to represent the load of the output shaft that change with time, the parameters include a variety of parameters, such as current, voltage, speed, etc. The measurement method may be sampling at a fixed period.

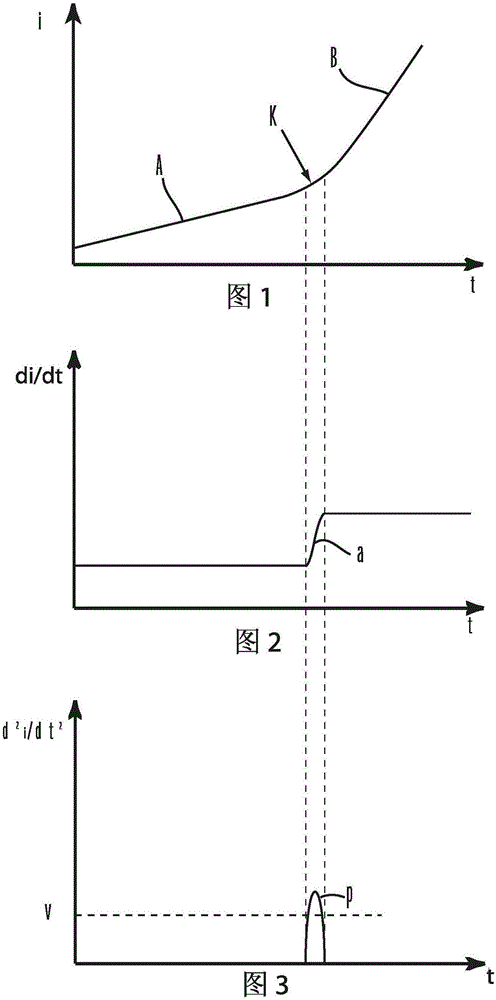

[0062] S2. Obtain the derivative of the parameter with respect to time, specifically, it can be a first-order derivative, a second-order derivative or a higher-order derivative. This derivative is actually the slope of the curve in FIG. 1 . There are many ways to calculate the derivative, which will be described in detail below.

[0063] S3, generating a corresponding control signal based on the derivative, that is, generating the control signal according to any one of the first-order derivative, second-order derivative or higher-order derivative. These derivatives...

Embodiment 2

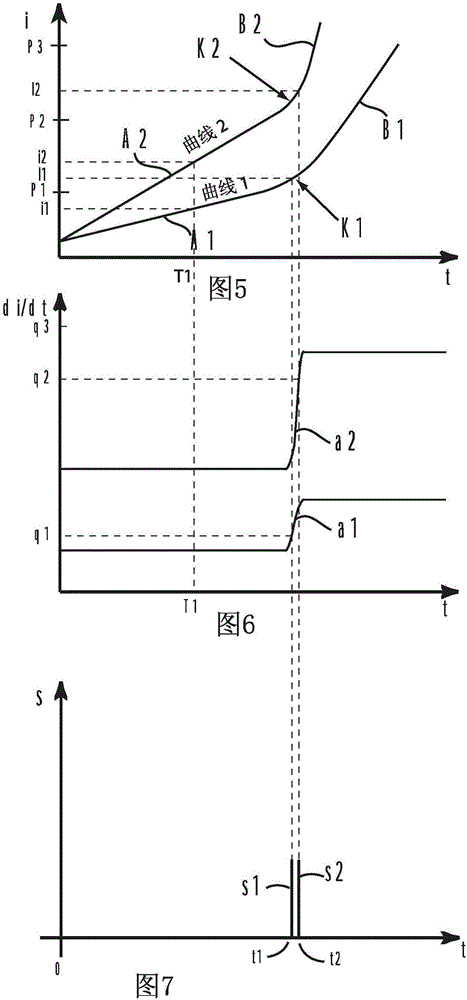

[0106] As described in the previous embodiment, Fig. 2 is the curve of the first derivative di / dt of current i versus time t in Fig. 1 picture . Among them, the first part A and the second part B in Figure 1 are in the picture The upper part is shown as a straight line parallel to the horizontal coordinate axis t, while the second part K is shown as a sharply rising curve.

[0107] Figure 3 is the second derivative d of the current i in Figure 1 with respect to time t 2 i / dt 2 after the curve picture . Among them, the values of the first part A and the second part B in Fig. 1 have become zero after the second derivative, while the second part K is shown as a parabola with an opening downward, and in the top area of the parabola (including the parabola A specific interval including the apex) forms a peak signal p. With reference Figure 4 As shown, when the peak signal p is formed, a control signal s will be generated accordingly. Of course, in a preferred embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com