Method of preparing C3N4/CaTi2O4(OH)2 composite material through solvothermal method

A technology of C3N4 and composite materials, which is applied in the field of photocatalysis, can solve the problems of difficult preparation and complex compounding, and achieve the effect of low cost, simple process and inhibiting compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

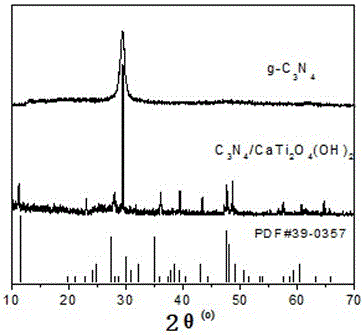

[0025] A kind of adopting solvothermal method to prepare C 3 N 4 / CaTi 2 o 4 (OH) 2 A method for composite materials, comprising the steps of:

[0026] Step 1: According to the molar ratio of butyl titanate:ethanol=1:5, dissolve butyl titanate in ethanol, stir until uniform to obtain A solution;

[0027] Step 2: Dissolve calcium chloride in distilled water according to the molar ratio of calcium chloride: distilled water: ethanol = 1: 400: 10, then add ethanol, and stir until uniform to obtain B solution;

[0028] Step 3: Add solution A dropwise into solution B under stirring, add 3ml of 3mol / L NaOH solution after stirring for 5 minutes, adjust the pH value to 8, continue stirring for 15 minutes, filter, and wash with distilled water for 6 times Dry in a vacuum oven at 90°C for 18 hours to form the precursor CaTi 2 o 4 (OH) 2 white precipitate;

[0029] Step 4: According to the precursor CaTi 2 o 4 (OH) 2 : ethanol: distilled water = 1:5:50, the precursor CaTi 2 o...

Embodiment 2

[0033] A kind of adopting solvothermal method to prepare C 3 N 4 / CaTi 2 o 4 (OH) 2 A method for composite materials, comprising the steps of:

[0034] Step 1: According to the molar ratio of isopropyl titanate:propanol=1:5, decompose isopropyl titanate in propanol, and stir until uniform to obtain A solution;

[0035] Step 2: Dissolve calcium chloride in distilled water according to the molar ratio of calcium chloride: distilled water: propanol=1:200:1, then add propanol, and stir until uniform to obtain B solution;

[0036] Step 3: Add solution A drop by drop into solution B under stirring, add 3.5ml of 3mol / L NaOH solution after stirring for 5 minutes, adjust the pH value to 8.5, continue stirring for 15 minutes, filter, and wash with distilled water 6 times Finally, dry it in a vacuum oven at 90°C for 24 hours to form the precursor CaTi 2 o 4 (OH) 2 white precipitate;

[0037] Step 4: According to the precursor CaTi 2 o 4 (OH) 2 : propanol: distilled water = 1:...

Embodiment 3

[0041] A kind of adopting solvothermal method to prepare C 3 N 4 / CaTi 2 o 4 (OH) 2 A method for composite materials, comprising the steps of:

[0042] Step 1: According to the molar ratio of titanium chloride:butanol=1:1, titanium chloride is dissolved in butanol, and stirred until uniform to obtain A solution;

[0043] Step 2: Dissolve calcium chloride in distilled water according to the molar ratio of calcium chloride: distilled water: butanol=1:300:5, then add butanol, and stir until uniform to obtain B solution;

[0044] Step 3: Add solution A dropwise into solution B under stirring, add 3.2ml of 3mol / L NaOH solution after stirring for 5 minutes, adjust the pH value to 8.2, continue stirring for 15 minutes, filter, and wash with distilled water 6 times Finally, dry it in a vacuum oven at 90°C for 20 hours to form the precursor CaTi 2 o 4 (OH) 2 white precipitate;

[0045] Step 4: According to the precursor CaTi 2 o 4 (OH) 2 : butanol: distilled water = 1:7:100...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap