Iron support for chemical test

A chemical test and iron stand technology, which is applied to chemical instruments and methods, laboratory utensils, supporting utensils, etc., can solve the problems of the height adjustment and rotation adjustment of the iron stand, the inseparability of the iron stand, etc. Ease of operation and increased tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

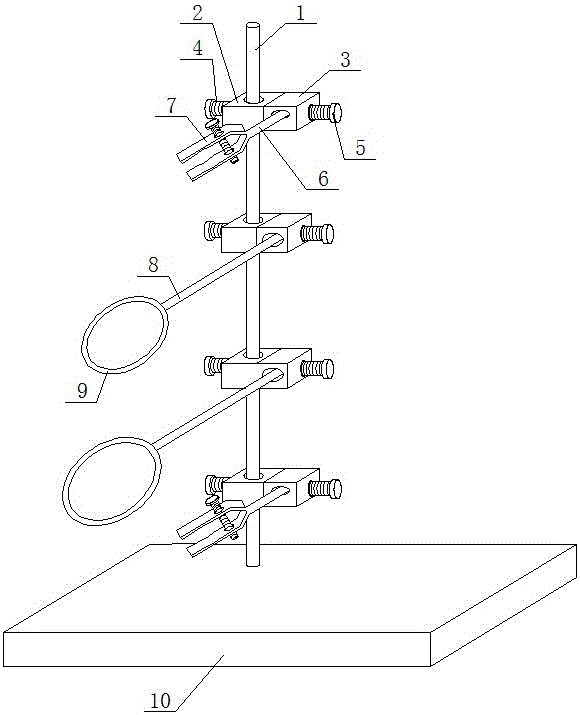

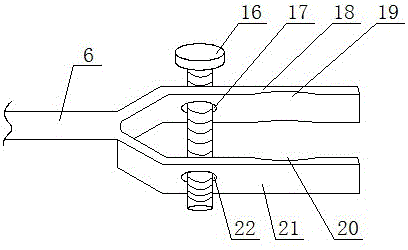

[0038] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, the chemical test iron frame platform of the present invention includes a base 10, a support rod 1, two test tube clamps and two iron rings, and each iron ring includes a connecting rod 8 and an outer end fixed on the connecting rod 8 Support rings 9, the diameters of the two support rings 9 are different; each test tube holder includes a rotating rod 6 and a clamping piece 7 fixed on the outer end of the rotating rod 6; the lower end of the supporting rod 1 is provided with external threads , The base 10 is provided with an installation threaded hole 11 for the support rod 1 to pass through, and the lower end of the support rod 1 is inserted into the installation threaded hole 11, that is, the support rod 1 and the base 10 are threaded. Four lifting mechanisms are arranged on the supporting rod 1, and the inner end of each connecting rod 8 and the inner end of each rotatin...

Embodiment 2

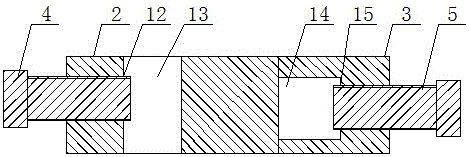

[0043] as attached Figure 5 ,. attached Figure 6 And attached Figure 7 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: the inner end of the fine-tuning bolt 4 is located in the fixing hole 13, and the inner end of the fine-tuning bolt 4 is fixed with a cross-section Arc-shaped support rod slot 23, the central axis of the support rod slot 23 is parallel to the central axis of the fixing hole 13, the support rod slot 23 can accommodate the support rod 1, when the fine-tuning bolt 4 is tightened to the right, the support rod The card slot 23 is inserted on the outer surface of the support rod 1, which increases the contact area between the fine-tuning bolt 4 and the support rod 1, thereby increasing the fastness of the support rod 1 in the fixing hole 13; at the same time, the positioning bolt 5 The inner end is located in the mounting hole 14, and the inner end of the positioning b...

Embodiment 3

[0046] as attached Figure 8 As shown, this embodiment is a further improvement on the basis of Embodiment 2. The difference between this embodiment and Embodiment 2 is that four support blocks 25 are fixed below the base 10, and the four support blocks 25 are distributed on the bottom of the base 10. On the four end corners; the base 10 has a receiving groove 26, the opening of the receiving groove 26 is located on the bottom surface of the base 10, and the opening of the receiving groove 26 is provided with a cover plate 27 slidably connected with it. Specifically, two guide rails are arranged on the opening of the accommodation groove 26, and the two guide rails are symmetrically fixed on the left and right sides of the opening of the accommodation groove 26, and the cover plate 27 is slidably connected on the two guide rails, the cover plate 27 and the accommodation groove 26 forms an openable or closed accommodating cavity, which can be used to place asbestos nets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com