Heat exchanger tube sheet assembling device and heat exchanger assembling and tube expanding device

A technology for assembling devices and heat exchanger tubes, which is applied in the directions of heat exchange equipment, feeding devices, positioning devices, etc., to achieve the effect of solving the problem of high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

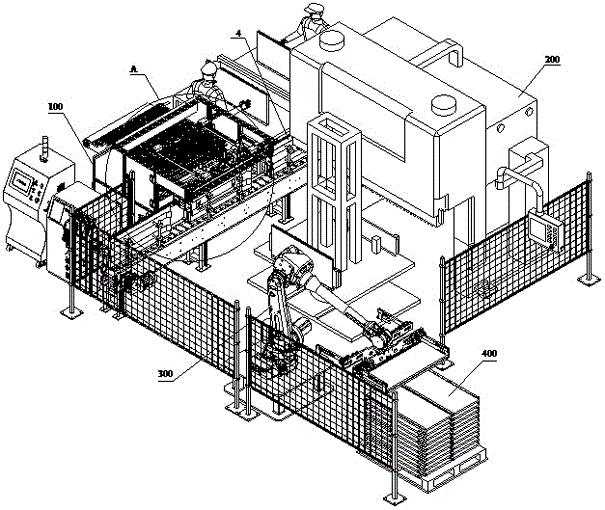

[0058] See figure 1 , the figure shows a perspective view of an embodiment of the device for assembling the expansion tubes of the heat exchanger based on the present invention, specifically, it is to realize the mechanical assembly of the tube sheet on the heat exchanger, and the mechanical handling of the installed A device that expands the heat exchanger behind the piping plate and transports it to the subsequent station.

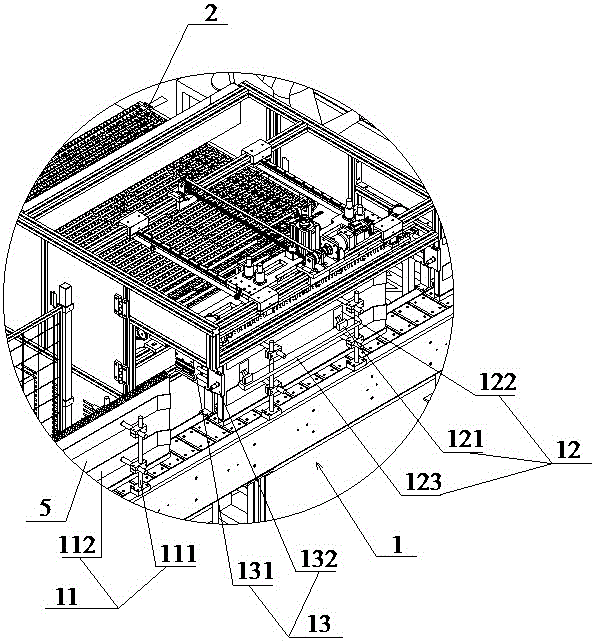

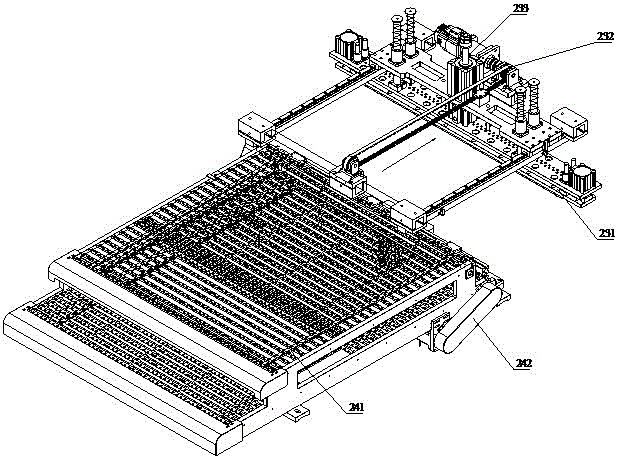

[0059] Such as figure 1 As shown, the heat exchanger assembling and expanding equipment of this embodiment includes a heat exchanger tube sheet assembling device 100 , a tube expander 200 and a heat exchanger handling device 300 . Wherein, the heat exchanger tube sheet assembly device 100 is used for assembling the tube she...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap