Preparing method of micrometer silver ball

A technology of silver balls and preparation steps, applied in the field of micron materials, can solve the problems of difficult operation, high requirements for equipment and experimental conditions, etc., and achieves the effects of mild conditions, improved synthesis efficiency and single product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

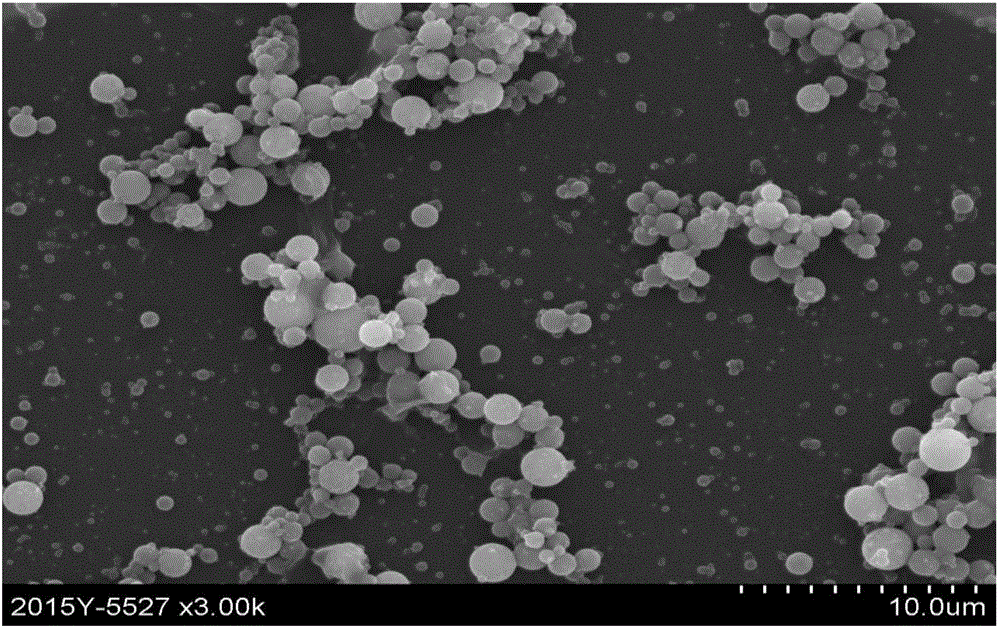

Image

Examples

Embodiment 1

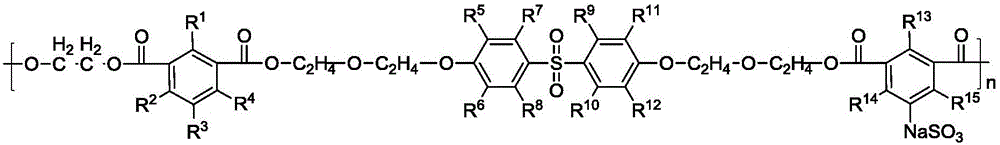

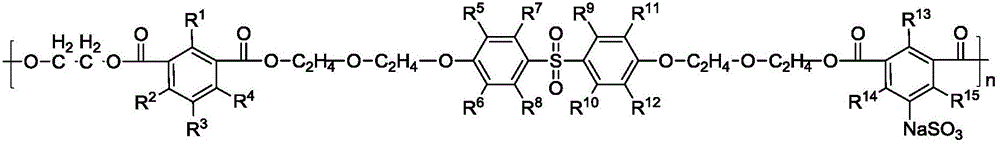

[0033] The modified polyester is synthesized according to the method reported in the patent document CN104672437A, the number average molecular weight is 11000, and its structural formula is:

[0034]

[0035] Dissolve 0.42g of silver nitrate in 10mL of ethylene glycol solvent for later use. Dissolve 0.77g of modified polyester with a number average molecular weight of 11,000 in 40mL of the same solvent, heat up to 140°C and stir. After stirring for one hour, add 0.25mL of 0.60mmol / L iron trichloride ethylene glycol solution, after stirring evenly, add the silver nitrate solution dropwise into the reaction, and stop heating after stirring for 8 hours. After cooling the obtained reaction mother liquor, dilute the reaction mother liquor with water and ethanol, centrifuge, collect the precipitate and disperse it with ethanol to obtain the product.

Embodiment 2

[0037] In the present embodiment, the synthesis of modified polyester is the same as in Example 1, and the number average molecular weight is 20000, and its structural formula is:

[0038]

[0039] Dissolve 0.42g of silver nitrate in 10mL of ethylene glycol solvent for later use. Dissolve 0.40g of modified polyester with a number average molecular weight of 20,000 in 40mL of the same solvent, and heat up to 130 ℃ Stir, after stirring for one hour, add 0.25mL of 0.60mmol / L iron trichloride ethylene glycol solution, stir evenly, add silver nitrate solution dropwise into the reaction, and stop heating after stirring for 6 hours. After cooling the obtained reaction mother liquor, dilute the reaction mother liquor with water and ethanol, centrifuge, collect the precipitate and disperse it with ethanol to obtain the product.

Embodiment 3

[0041] In the present embodiment, the synthesis of modified polyester is the same as in Example 1, and the number average molecular weight is 11000, and its structural formula is:

[0042]

[0043] Dissolve 0.71g of silver nitrate in 10mL of ethylene glycol solvent for later use. Dissolve 0.40g of modified polyester with a number average molecular weight of 11000 in 40mL of the same solvent and raise the temperature to 130 ℃ Stir, after stirring for one hour, add 0.25mL of 0.60mmol / L iron trichloride ethylene glycol solution, stir evenly, add the silver nitrate solution dropwise into the reaction, and stop heating after stirring for 8 hours. After cooling the obtained reaction mother liquor, dilute the reaction mother liquor with water and ethanol, centrifuge, collect the precipitate and disperse it with ethanol to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com