Machining rocker arm type clamp device

A fixture device and rocker-type technology, applied in the field of machining fixtures, can solve problems such as inability to guarantee machining safety and machining accuracy, self-locking can not guarantee the clamping performance of the fixture, and insufficient clamping force of the fixture, so that it is not easy to loosen. Good detachment and locking performance, sufficient locking force of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

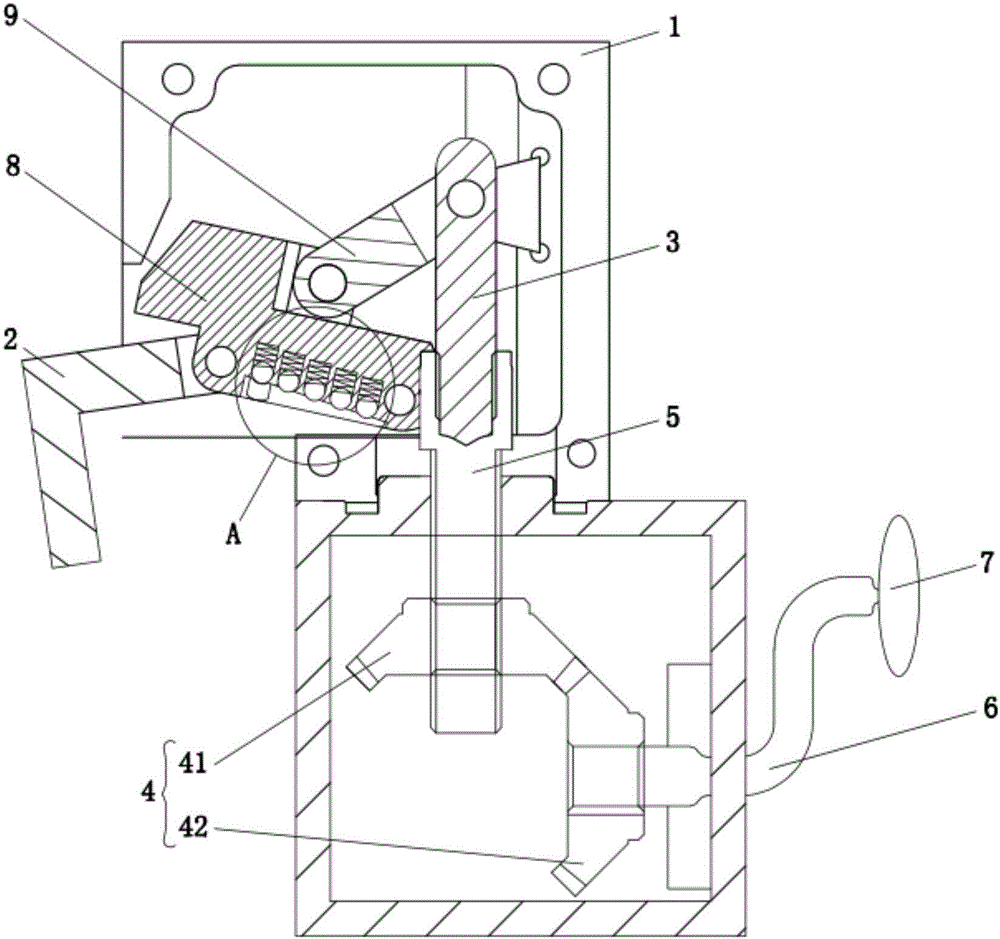

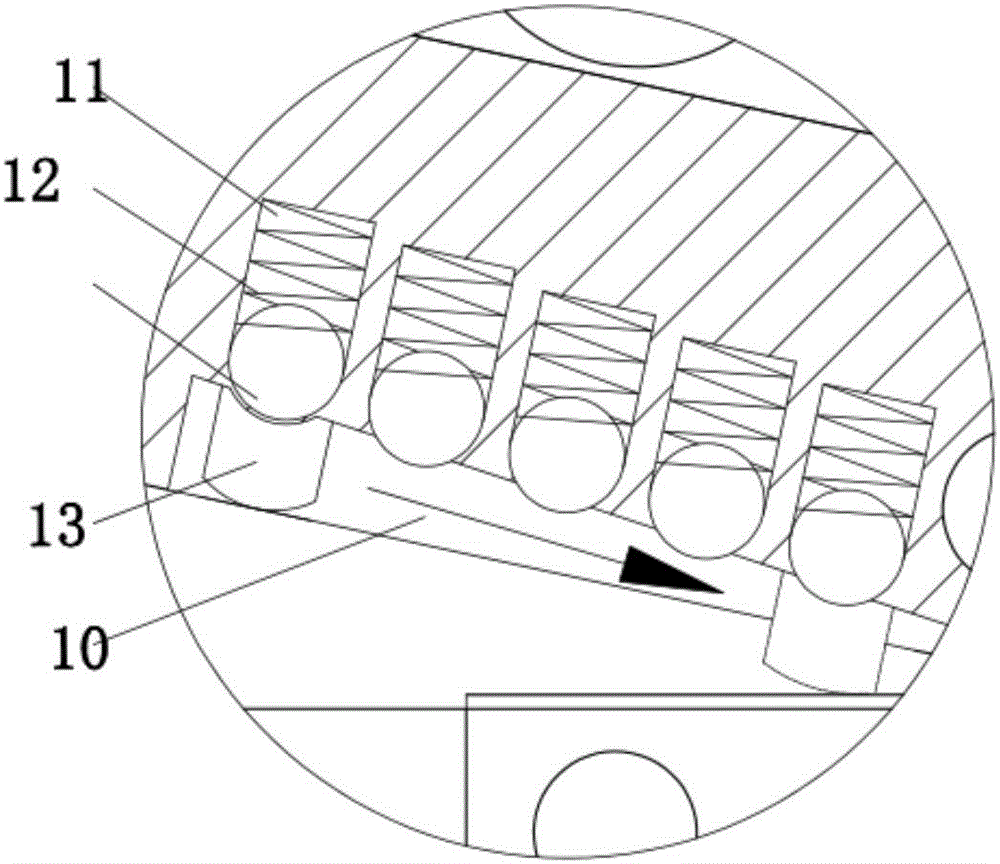

[0019] The specific embodiment of the present invention is as figure 1 , 2 As shown, a machined rocker-arm clamp device includes a housing 1, a lock 2, a self-locking mechanism with gear positions, a drive rod 3 and a bevel gear 4, and the lower end of the drive rod 3 is connected to a screw rod 5, The bevel gear 4 includes a first bevel gear 41 and a second bevel gear 42, the first bevel gear 41 is provided with an internal thread that cooperates with the screw mandrel 5, and the second bevel gear 42 and the first bevel gear 41 are mutually Matching and forming a certain angle, the crank handle 6 is inserted in the inner hole of the second bevel gear 42 .

[0020] One end of the crank handle 6 outside the shell is provided with a handle 7 , and the other end of the crank handle 6 is set inside the shell 1 .

[0021] The housing 1 is connected with a self-locking mechanism, and the self-locking mechanism includes a gear position self-locking arm 8 and a self-locking lever 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com