Mounting bracket capable of being regulated in multiple directions for spray head of ink-jet printing machine

A technology for installing brackets and inkjet printers, which is used in power transmission devices, printing, transfer materials, etc., and can solve the problem of inability to achieve adjustment and fine-tuning in multiple directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

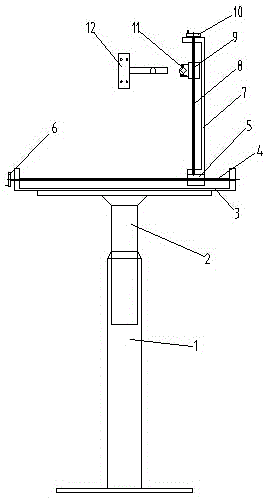

[0008] A multi-directional adjustable inkjet printer nozzle installation bracket, the installation bracket includes a bracket base 1, a horizontal screw pair, a vertical screw pair, a nozzle connecting plate 12 and a hinge clamping device 11, and the bracket carriage 2 inserted into the support base 1, the height of the entire support can be easily adjusted to facilitate the center height of each production line, the horizontal screw pair is arranged on the support carriage 2, and the horizontal screw pair includes a horizontal screw 4. Horizontal lead screw base 3, horizontal drag plate 5, horizontal hand wheel 6, the horizontal hand wheel 6 drives the horizontal screw rod 4 and drives the horizontal drag plate 5 to move back and forth, and the vertical lead screw pair is arranged on the horizontal drag On the plate 5, the vertical screw pair includes a vertical screw 8, a vertical screw base 7, a vertical carriage 9, and a vertical handwheel 10, and the vertical handwheel 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com