Cone yarn packaging line

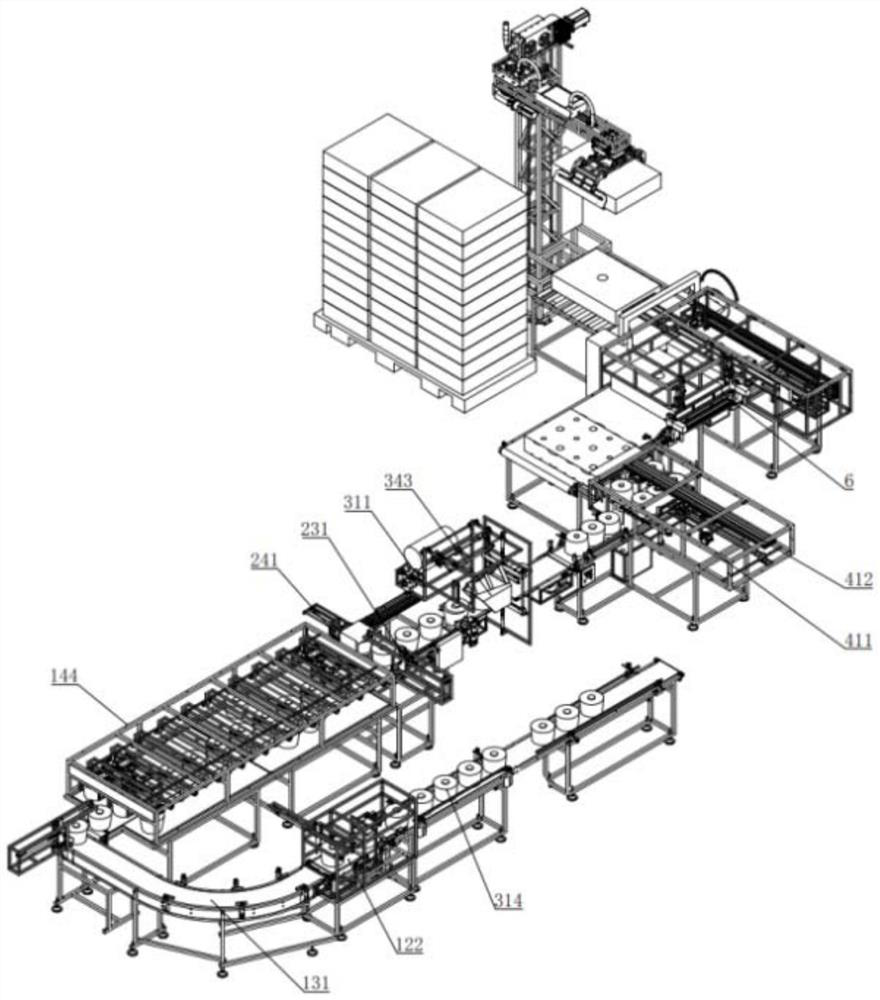

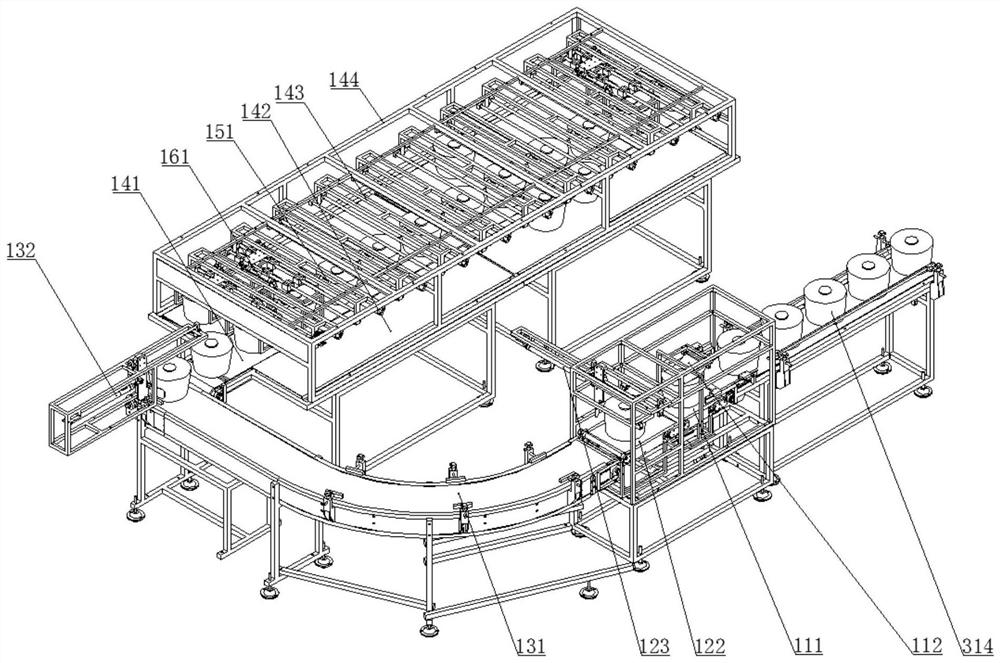

A packaging line and bobbin technology, which is applied in the field of bobbin packaging line, can solve the problems of low packaging efficiency, heavy workload of workers, difficulty in ensuring packaging accuracy and quality, and achieve the effect of improving accuracy and increasing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

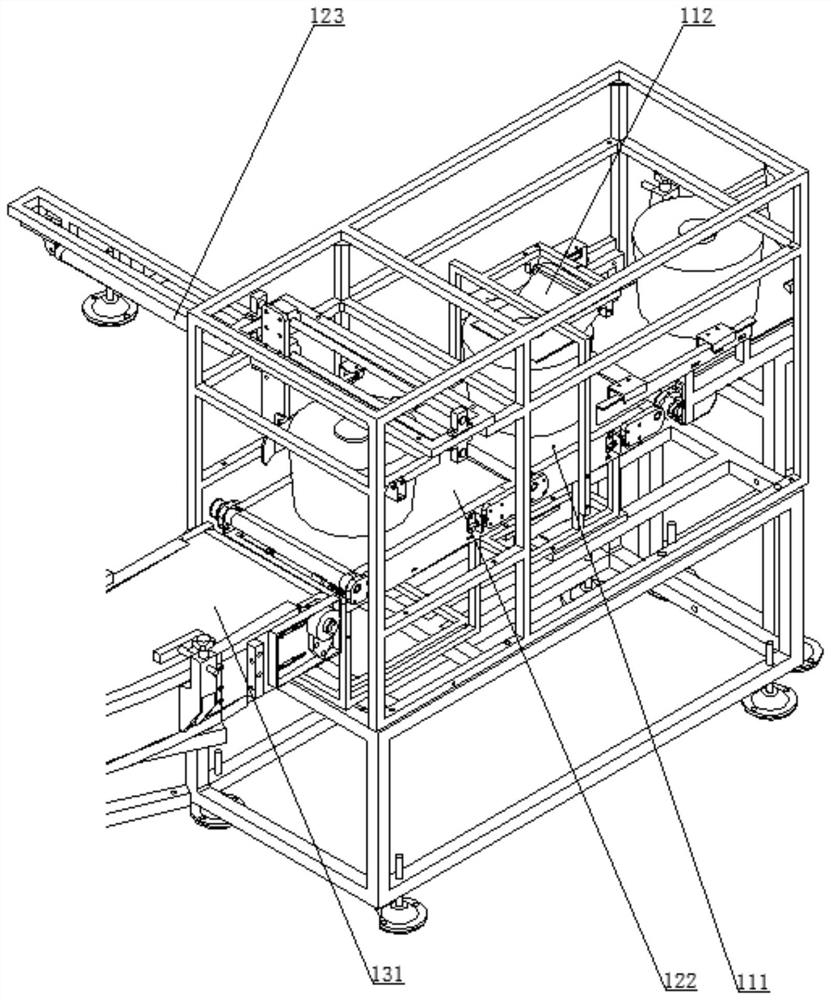

[0031] Preferably, the bobbin counterweight mechanism also includes a clamping cylinder 161, one end of the clamping cylinder 161 is connected to the clamping first frame body 162, and the other end is connected to the clamping second frame body 163; A second slider 153 is fixedly connected to the frame body 163, and the second slider 153 is slidingly connected with the push slide rail 154. The clamping first frame body 162 is parallel to the clamping second frame body 163 and partly Overlap settings. It should be noted that if Figure 4 and Figure 5One embodiment shown: the first slider 159 in the figure is fixed on the clamping first frame body 162, the slider 152 is located between the first sliders 159, and the slider 152 can collide with the first slider 159 Drive and clamp the first frame body 162 and clamp the second frame body 163 to act together, and the clamping cylinder 161 can drive the clamping first frame body 162 and the clamping second frame body 163 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com